4919349

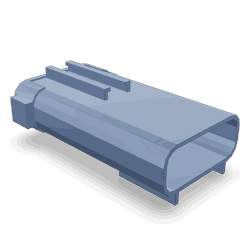

Electrical Connector

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4919349 Electrical Connector is a specialized component designed for use in commercial truck operations. Its purpose is to facilitate secure and reliable electrical connections within the truck’s electrical system. This connector plays a role in ensuring the proper functioning of various electrical components and systems in commercial trucks.

Basic Concepts of Electrical Connectors

Electrical connectors are devices used to join electrical circuits together, allowing the transfer of electrical power and signals between different components. In automotive applications, these connectors ensure that all electrical systems, such as lighting, sensors, and control units, operate correctly and efficiently. They are designed to withstand various environmental conditions, including vibrations, temperature fluctuations, and moisture 1.

Purpose of the Cummins 4919349 Electrical Connector

The Cummins 4919349 Electrical Connector is specifically designed to play a role in the electrical system of a truck by providing a secure connection point for various electrical components. It ensures that the electrical signals and power are transmitted reliably between different parts of the truck’s electrical system, contributing to the overall functionality and performance of the vehicle.

Key Features

The Cummins 4919349 Electrical Connector features a robust design that includes high-quality materials to ensure durability and reliability. It is constructed using materials that can resist corrosion and wear, enhancing its longevity. The connector also incorporates unique characteristics such as weather-sealing and vibration resistance, which are crucial for maintaining performance in the demanding conditions typical of commercial truck operations 2.

Benefits

The Cummins 4919349 Electrical Connector offers several benefits, including improved reliability in electrical connections, enhanced efficiency in signal and power transmission, and increased safety by ensuring secure and stable connections. These factors contribute to the overall performance and longevity of the truck’s electrical system.

Installation and Usage

Proper installation of the Cummins 4919349 Electrical Connector involves following manufacturer guidelines to ensure a secure and correct connection. Best practices include verifying that the connector is compatible with the specific electrical system it will be used in, ensuring all connections are tight and secure, and protecting the connector from environmental factors that could affect its performance 3.

Troubleshooting and Maintenance

Common issues with the Cummins 4919349 Electrical Connector may include loose connections, corrosion, or damage from environmental factors. Troubleshooting involves inspecting the connector for signs of wear or damage, ensuring all connections are secure, and cleaning or replacing the connector if necessary. Regular maintenance, such as checking for corrosion and ensuring connections are tight, can help prevent issues and ensure optimal performance.

Common Failures and Solutions

Common failure modes for the Cummins 4919349 Electrical Connector may include corrosion, physical damage, or wear from repeated use. Solutions to these issues may involve cleaning the connector, tightening connections, or replacing the connector if it is damaged beyond repair. Regular inspections and maintenance can help identify potential issues before they lead to failures.

Integration with Other Systems

The Cummins 4919349 Electrical Connector integrates with various truck systems and components, including the engine control unit, sensors, and lighting systems. This integration enhances the overall performance of the vehicle by ensuring reliable electrical connections across these systems, contributing to efficient operation and reduced downtime.

Safety Considerations

When working with the Cummins 4919349 Electrical Connector, it is important to follow safety considerations to prevent injury and ensure the connector functions correctly. This includes handling the connector with care to avoid damage, ensuring the electrical system is de-energized during installation or maintenance, and following all manufacturer guidelines for safe use.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history of innovation and quality, Cummins plays a significant role in the automotive industry, particularly in the production of high-quality truck components that enhance vehicle performance and reliability.

Role of Part 4919349 Electrical Connector in Engine Systems

Integration with Tool Certification Kit

The 4919349 Electrical Connector is instrumental in the functionality of a Tool Certification Kit. This kit is designed to ensure that tools used in engine maintenance meet specific standards and perform reliably. The electrical connector facilitates the secure and efficient transfer of data between the certification tool and the engine’s electronic control unit (ECU). This connection allows for the accurate monitoring of tool performance, ensuring that all diagnostic and repair processes adhere to manufacturer specifications. The connector’s robust design ensures that data transmission is consistent and free from interference, which is essential for precise tool certification.

Application in Wiring Harness Repair Kit

In the context of a Wiring Harness Repair Kit, the 4919349 Electrical Connector plays a significant role in restoring and maintaining the integrity of the engine’s electrical system. When repairing a wiring harness, it is vital to ensure that all connections are secure and reliable to prevent issues such as short circuits or data loss. The electrical connector provides a dependable link between various components within the wiring harness, such as sensors, actuators, and the ECU. Its design allows for easy installation and removal, which simplifies the repair process and reduces downtime. Additionally, the connector’s durability ensures that it can withstand the harsh conditions often found in engine compartments, such as high temperatures and vibrations, thereby prolonging the lifespan of the repair.

Conclusion

The Cummins 4919349 Electrical Connector is a vital component in the electrical systems of commercial trucks, ensuring reliable connections and efficient operation. Its robust design, integration with various systems, and role in maintenance kits highlight its importance in maintaining vehicle performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.