This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

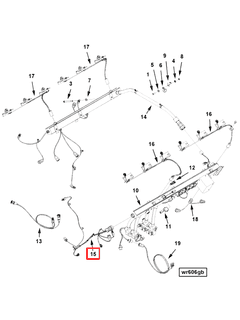

The 4928133 Electronic Control Module Wiring Harness is a vital component in the electrical system of commercial trucks. It facilitates the connection between the Electronic Control Module (ECM) and various sensors and actuators throughout the vehicle. This harness ensures that the ECM receives accurate data from the sensors and can effectively control the truck’s systems, contributing to overall operational efficiency and reliability.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a collection of wires and connectors that link the ECM to the truck’s various electrical components. It includes multiple wires, each serving a specific function, and connectors that ensure secure and reliable connections. The harness functions by transmitting signals and power between the ECM and other systems, allowing for precise control and monitoring of the truck’s operations 1.

Role of the 4928133 Electronic Control Module Wiring Harness in Truck Operation

The 4928133 Wiring Harness plays a significant role in the operation of a truck by enabling communication between the ECM and other critical systems. It ensures that the ECM receives real-time data from sensors, which it uses to make adjustments to the engine, transmission, and other systems. This harness also allows the ECM to send commands to actuators, ensuring that the truck operates smoothly and efficiently.

Key Features of the 4928133 Wiring Harness

The 4928133 Wiring Harness boasts several key features that enhance its performance and reliability. These include:

- Durability: Constructed from high-quality materials, the harness is designed to withstand the harsh conditions often encountered in commercial trucking.

- Design: The harness is engineered to fit precisely within the truck’s electrical system, ensuring a secure and reliable connection.

- Integration Capabilities: It is compatible with a wide range of sensors and actuators, allowing for versatile applications across different truck models.

Benefits of Using the 4928133 Wiring Harness

Utilizing the 4928133 Wiring Harness offers several advantages:

- Improved Reliability: The high-quality construction and precise design contribute to a more reliable electrical system.

- Efficiency: By ensuring accurate data transmission and control signals, the harness helps maintain optimal truck performance.

- Ease of Maintenance: The harness is designed for straightforward installation and maintenance, reducing downtime and repair costs.

Installation Considerations

Proper installation of the 4928133 Wiring Harness is crucial for its effective operation. Key considerations include:

- Following Manufacturer Guidelines: Adhering to the installation instructions provided by Cummins ensures correct setup.

- Ensuring Secure Connections: All connections should be tight and secure to prevent signal loss or electrical issues.

- Avoiding Common Pitfalls: Careful routing of the harness and protection from physical damage are important to maintain its integrity.

Troubleshooting Common Issues

When issues arise with the 4928133 Wiring Harness, systematic troubleshooting can help identify and resolve problems:

- Check Connections: Ensure all connectors are securely attached and free from corrosion.

- Inspect for Damage: Look for any signs of wear, fraying, or physical damage to the wires.

- Use Diagnostic Tools: Employ diagnostic equipment to test the harness and identify any faults.

Maintenance Tips

Regular maintenance of the 4928133 Wiring Harness can extend its lifespan and ensure optimal performance:

- Periodic Inspections: Regularly check the harness for signs of wear or damage.

- Clean Connections: Keep connectors clean and free from debris to ensure reliable connections.

- Protect from Elements: Shield the harness from extreme temperatures and moisture to prevent degradation.

Safety Considerations

When working with the 4928133 Wiring Harness, several safety considerations should be observed:

- Disconnect Power: Always ensure the truck’s electrical system is powered down before working on the harness.

- Use Proper Tools: Employ the correct tools to avoid damaging the harness or connectors.

- Follow Safety Protocols: Adhere to all safety guidelines and protocols to prevent accidents and injuries.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. Their product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding needs of commercial trucking.

Electronic Control Module Wiring Harness (Part 4928133) Compatibility with Cummins Engines

The Electronic Control Module (ECM) Wiring Harness, identified by part number 4928133, is a critical component designed to ensure seamless communication and power distribution between the ECM and various engine control units. This wiring harness is engineered to fit specific Cummins engines, ensuring optimal performance and reliability.

Compatibility with QSK38 Engines

The ECM Wiring Harness 4928133 is compatible with the QSK38 engines, specifically the QSK38 CM2150 MCRS and QSK38 CM850 MCRS models. These engines are known for their robust design and high performance, making them suitable for a variety of heavy-duty applications. The wiring harness is meticulously designed to interface with the ECM, ensuring that all necessary signals and power are correctly routed to maintain engine efficiency and responsiveness.

Ensuring Proper Fitment

When installing the ECM Wiring Harness 4928133 on QSK38 engines, it is crucial to follow the manufacturer’s guidelines to ensure a proper fit. This includes verifying that the harness is correctly routed to avoid interference with other components and ensuring that all connections are secure and properly seated. The harness is designed to withstand the rigors of heavy-duty operation, providing a reliable connection that can endure the demanding conditions these engines operate under.

Importance of Correct Installation

Correct installation of the ECM Wiring Harness is essential for the overall health and performance of the engine. An improperly installed harness can lead to communication errors, power supply issues, and potential engine malfunctions. It is recommended to use the appropriate tools and follow the detailed installation instructions provided by Cummins to ensure that the harness is installed correctly and securely.

Grouping for Ease of Reference

For ease of reference, the ECM Wiring Harness 4928133 is grouped with the QSK38 engines, highlighting its specific compatibility with these models. This grouping helps users quickly identify the correct part for their engine, ensuring that they have the necessary components for a successful installation.

Role of Part 4928133 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified by part number 4928133, serves as the vital connective tissue within engine systems, ensuring seamless communication and power distribution between the ECM and various engine components.

Integration with Engine Components

-

Sensors: The harness facilitates the connection of numerous sensors, such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and Manifold Absolute Pressure (MAP) sensor. These sensors provide real-time data to the ECM, allowing for precise control of fuel injection, ignition timing, and emissions 2.

-

Actuators: It links actuators like the fuel injectors, idle air control (IAC) valve, and throttle position sensor (TPS). This ensures that the ECM can execute commands based on sensor inputs, optimizing engine performance and efficiency.

-

Ignition System: The harness interfaces with the ignition system components, including the ignition coil and spark plugs. It enables the ECM to control the timing and duration of spark events, crucial for combustion efficiency.

-

Emission Control Systems: It connects components of the emission control system, such as the Exhaust Gas Recirculation (EGR) valve and the catalytic converter. This allows the ECM to manage emissions in compliance with environmental regulations 3.

-

Battery and Alternator: The harness includes connections to the battery and alternator, ensuring that the ECM receives a stable power supply. This is essential for the ECM to function correctly, especially during engine start-up and operation.

-

Grounding Points: It provides multiple grounding points to ensure a stable electrical environment, reducing the risk of electrical noise and ensuring accurate signal transmission between the ECM and other components.

Functional Synergy

The ECM Wiring Harness operates in concert with the ECM to monitor and adjust engine parameters in real-time. This dynamic interaction allows for optimal engine performance under varying conditions, whether the engine is idling, accelerating, or decelerating. The harness’s robust design ensures durability and reliability, even in the harsh environment of an engine compartment.

Conclusion

In summary, the ECM Wiring Harness (part 4928133) is integral to the functioning of modern engine systems, enabling the ECM to effectively manage and optimize engine operations through its connections to sensors, actuators, and other critical components.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.