4963807

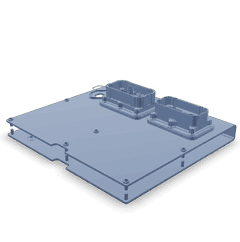

Electronic Control Module

Cummins®

AVAILABLE

4 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4963807 Electronic Control Module (ECM) by Cummins is a sophisticated component designed to enhance the operation of commercial trucks. This ECM is integral to the truck’s engine management system, contributing to improved engine performance and efficiency. By optimizing various engine parameters, the 4963807 ECM ensures that commercial trucks operate more effectively, meeting both performance and regulatory requirements 1.

Basic Concepts of Electronic Control Modules

An Electronic Control Module (ECM) is a computerized device that manages and controls various functions within a truck’s engine management system. It processes data from multiple sensors and actuators to regulate engine operations. The ECM operates based on pre-programmed algorithms that adjust engine parameters in real-time to optimize performance, fuel efficiency, and emissions control. Its role is pivotal in maintaining the balance between power output and efficiency 2.

Purpose of the 4963807 ECM

The 4963807 ECM is specifically designed to manage and optimize the engine’s operations in commercial trucks. It oversees engine control by adjusting fuel injection timing, air-fuel ratio, and ignition timing. Additionally, the ECM plays a role in emissions management by ensuring that the engine complies with environmental regulations. It also contributes to overall performance optimization by enhancing the truck’s responsiveness and efficiency under various driving conditions 1.

Key Features

The 4963807 ECM boasts several key features that enhance its functionality. It is equipped with robust processing power and ample memory capacity, allowing it to handle complex calculations and store extensive data. The ECM offers various connectivity options, enabling it to communicate with other vehicle systems and diagnostic tools. It incorporates unique technologies and designs that improve its reliability and performance, ensuring that it can withstand the demanding conditions of commercial truck operations 3.

Benefits of Using the 4963807 ECM

Utilizing the 4963807 ECM in commercial trucks offers numerous advantages. It contributes to improved fuel efficiency by optimizing engine operations, resulting in cost savings for fleet operators. The ECM enhances engine performance by ensuring that the engine operates within its optimal parameters. It also plays a role in better emissions control, helping trucks meet stringent environmental regulations. Additionally, the ECM increases the reliability of the engine system, reducing the likelihood of unexpected breakdowns and maintenance issues 1.

Integration with Other Systems

The 4963807 ECM interacts seamlessly with other components and systems within the truck. It communicates with the engine, transmission, and various sensors to ensure coordinated operation. This integration allows the ECM to make real-time adjustments based on data from these systems, enhancing the truck’s overall performance and efficiency. The ECM’s ability to interface with other systems ensures that the truck operates smoothly and efficiently under diverse conditions 3.

Diagnostic Capabilities

The 4963807 ECM is equipped with advanced diagnostic features that enable it to monitor engine health and detect faults. It continuously collects data from various sensors and can identify issues such as misfires, sensor malfunctions, and other abnormalities. The ECM provides valuable data for maintenance and repair, allowing technicians to diagnose problems quickly and accurately. This capability helps maintain the truck’s performance and prolong its operational life 1.

Programming and Updates

The 4963807 ECM can be programmed and updated to adapt to changing conditions or regulations. The process for software updates and calibrations involves connecting the ECM to a diagnostic tool and following the manufacturer’s instructions. Regular updates ensure that the ECM continues to operate efficiently and comply with the latest emissions standards. Programming the ECM allows fleet operators to customize engine parameters to suit specific operational needs 3.

Troubleshooting and Maintenance

To ensure the longevity and optimal performance of the 4963807 ECM, it is important to follow troubleshooting and maintenance guidelines. Common issues with the ECM can often be resolved by checking connections, updating software, and performing diagnostic tests. Regular maintenance, such as cleaning connectors and ensuring proper ventilation, helps prevent problems. Best practices for handling and installation, including avoiding exposure to moisture and extreme temperatures, are crucial for the ECM’s reliable operation 1.

Cummins Corporation

Cummins Corporation is a renowned manufacturer with a long-standing reputation in the industry for innovation and quality. Founded in 1919, Cummins has been at the forefront of engine technology, providing reliable and high-performance engine components for various applications. The company’s commitment to research and development ensures that its products, including the 4963807 ECM, meet the highest standards of quality and performance. Cummins’ dedication to customer satisfaction and technological advancement solidifies its position as a leader in the engine manufacturing sector 3.

Compatibility with Cummins Engines

The Electronic Control Module (ECM) part number 4963807, manufactured by Cummins, is designed to integrate seamlessly with a range of Cummins engines. This ECM is engineered to provide precise control and monitoring of engine operations, ensuring optimal performance and efficiency.

ISM CM876 Series

The ECM part 4963807 is compatible with the ISM CM876 engine, which is known for its robust performance and reliability in heavy-duty applications. This ECM ensures that the engine operates within its optimal parameters, enhancing fuel efficiency and reducing emissions 3.

ISM11 CM876 SN Series

For the ISM11 CM876 SN engine, the ECM part 4963807 offers advanced control features that cater to the specific needs of this engine variant. It provides enhanced diagnostics and communication capabilities, ensuring that the engine performs at its best under various operating conditions 3.

QSM11 Series

The ECM part 4963807 is also suitable for the QSM11 engines, including the QSM11 CM570 and QSM11 CM876. This ECM is designed to work with the unique specifications of the QSM11 series, providing precise control over engine functions and ensuring reliable performance 3.

QSN14 Series

In the QSN14 CM876 N103 engine, the ECM part 4963807 plays a crucial role in managing engine operations. It is engineered to handle the specific requirements of this engine variant, ensuring that it operates efficiently and reliably 3.

QSNT14 Series

Similarly, for the QSNT14 CM876 N102 engine, the ECM part 4963807 provides the necessary control and monitoring functions. This ECM is designed to integrate with the QSNT14 series, ensuring that the engine performs optimally under various conditions 3.

By using the ECM part 4963807, operators can expect improved engine performance, enhanced diagnostics, and better overall reliability across these Cummins engine models.

Role of Part 4963807 Electronic Control Module in Engine Systems

The Electronic Control Module (ECM) part 4963807 is integral to the operation of modern engine systems. It serves as the central processing unit, managing and coordinating various engine functions to ensure optimal performance and efficiency.

Integration with Engine Components

-

Engine Control Module (ECM): Part 4963807 works in tandem with the ECM to regulate fuel injection, ignition timing, and other critical engine parameters. It processes data from various sensors and adjusts engine operations in real-time to maintain performance standards 3.

-

Electronic Service Calibration: This module is essential for calibrating the engine’s electronic systems. Part 4963807 facilitates the fine-tuning of engine parameters, ensuring that the engine operates within specified tolerances and meets emission standards 3.

-

Sensors and Actuators: The ECM interfaces with a network of sensors (such as oxygen sensors, throttle position sensors, and mass airflow sensors) and actuators (like fuel injectors and ignition coils). It uses the data from these components to make precise adjustments, enhancing engine efficiency and responsiveness 2.

-

Communication Networks: Part 4963807 is part of the engine’s communication network, often utilizing protocols like CAN (Controller Area Network) to exchange data with other vehicle systems. This integration allows for comprehensive vehicle management, from transmission control to emissions monitoring 3.

-

Diagnostic Systems: The module plays a key role in onboard diagnostics (OBD). It monitors engine health, detects malfunctions, and stores diagnostic trouble codes (DTCs), which are vital for maintenance and repair processes 1.

-

Performance Optimization: By continuously analyzing engine performance data, part 4963807 helps in optimizing engine operation under various driving conditions. This includes adjustments for altitude, temperature, and load, ensuring consistent performance 3.

Conclusion

In summary, the 4963807 Electronic Control Module is a pivotal component in modern engine systems, enhancing functionality, efficiency, and reliability through sophisticated control and monitoring capabilities. Its integration with various engine components and systems ensures that commercial trucks operate at peak performance, meeting both regulatory and operational requirements 123.

-

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩ ↩ ↩ ↩ ↩ ↩ ↩ -

Osgood, Libby, Gayla Cameron, and Emma Christensen. Engineering Mechanics: Statics. Creative Commons, 2024.

↩ ↩ ↩ -

ElSayed, Mohamed PE. Fundamentals of Integrated Vehicle Realization. SAE International, 2017.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.