This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

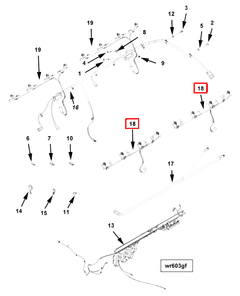

The 4964235 Electronic Control Module Wiring Harness, produced by Cummins, is a critical component in the operation of heavy-duty trucks. This wiring harness facilitates communication between the Electronic Control Module (ECM) and various truck components, ensuring efficient and reliable performance.

Basic Concepts

The ECM acts as the central processing unit of the truck’s electronic system, overseeing and regulating various functions. The wiring harness provides the necessary electrical connections for the ECM to communicate with different truck components, which is essential for coordinating engine performance, emissions control, and other systems 1.

Purpose and Functionality

The 4964235 Wiring Harness is designed to enable the ECM to effectively monitor and control engine performance, emissions, and other systems within the truck. It ensures that the ECM receives accurate data from sensors and can send appropriate signals to actuators and other components, maintaining optimal engine operation and compliance with emissions standards 2.

Key Features

This Cummins part is characterized by its robust design and the use of high-quality materials. These features contribute to its durability and performance under the demanding conditions typical of heavy-duty truck operations. The harness is engineered to withstand vibrations, temperature fluctuations, and exposure to chemicals, ensuring long-term reliability 3.

Benefits

Utilizing the 4964235 Wiring Harness offers several advantages. It contributes to improved engine efficiency by ensuring precise communication between the ECM and engine components. Additionally, it enhances diagnostic capabilities, allowing for more accurate identification of issues. The harness also increases the reliability of the truck’s electronic systems, leading to reduced downtime and maintenance costs.

Installation and Integration

Proper installation and integration of the 4964235 Wiring Harness are crucial for its effective operation. It is important to follow manufacturer guidelines to ensure compatibility with other components within the truck’s electronic system. Careful attention to detail during installation helps prevent issues related to electrical connectivity and ensures the harness functions as intended.

Troubleshooting and Maintenance

Common issues with the Electronic Control Module Wiring Harness can often be traced to physical damage, corrosion, or loose connections. Regular inspection and maintenance can help identify and address these issues before they lead to more significant problems. Keeping the harness clean and free from debris, and ensuring all connections are secure, are important maintenance practices.

Safety Considerations

When working with the 4964235 Wiring Harness, it is important to observe safety precautions. This includes ensuring the truck’s battery is disconnected before beginning any work to prevent electrical shocks. Additionally, using the appropriate tools and following safety guidelines can help protect against injuries and ensure the integrity of the wiring harness and other components.

Cummins Overview

Cummins Inc. has a long-standing reputation in the automotive industry, particularly for its contributions to the heavy-duty truck sector. With a history of innovation and quality, Cummins continues to be a trusted name in the production of components that enhance the performance, efficiency, and reliability of heavy-duty trucks.

Role of the 4964235 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified by part number 4964235, serves as the vital link between the ECM and various engine components. This harness facilitates the transmission of electrical signals, ensuring seamless communication and coordination among the engine’s electronic systems.

Integration with Engine Components

-

Sensors: The ECM Wiring Harness connects to a multitude of sensors, such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and Manifold Absolute Pressure (MAP) sensor. These sensors provide real-time data on air intake, oxygen levels, and pressure within the intake manifold, allowing the ECM to make precise adjustments to fuel delivery and ignition timing.

-

Actuators: This harness also interfaces with actuators, including the fuel injectors, throttle body, and variable valve timing (VVT) solenoids. By receiving signals from the ECM, these actuators adjust fuel injection, throttle position, and valve timing to optimize engine performance and efficiency.

-

Ignition System: The ECM Wiring Harness is integral to the ignition system, connecting to the ignition coil(s) and spark plugs. It ensures that the ECM can control the timing and intensity of the spark, which is essential for efficient combustion.

-

Emission Control Systems: Components like the Exhaust Gas Recirculation (EGR) valve and the Evaporative Emission Control (EVAP) system rely on the ECM Wiring Harness for operation. The harness allows the ECM to monitor and control these systems to reduce emissions and meet regulatory standards.

-

Battery and Alternator: The harness also includes connections to the battery and alternator, ensuring that the ECM receives a stable power supply. This is essential for the ECM to function correctly, especially during engine start-up and under varying load conditions.

-

Communication Networks: In modern engines, the ECM Wiring Harness often includes connections to the Controller Area Network (CAN) bus. This allows the ECM to communicate with other control modules in the vehicle, such as the Transmission Control Module (TCM) and the Anti-lock Braking System (ABS) module, enhancing overall vehicle performance and safety.

By providing a robust and reliable electrical connection between the ECM and these various components, the ECM Wiring Harness ensures that the engine operates efficiently, responds accurately to driving conditions, and complies with emission regulations.

Conclusion

The 4964235 Electronic Control Module Wiring Harness is a vital component in the operation of heavy-duty trucks. Its role in facilitating communication between the ECM and various engine components ensures efficient engine performance, accurate emissions control, and reliable operation of the truck’s electronic systems. Proper installation, regular maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this Cummins part.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar Agarwal. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer, 2019.

↩ -

Happian-Smith, Julian. An Introduction to Modern Vehicle Design. Butterworth-Heinemann, 2002.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.