4964240

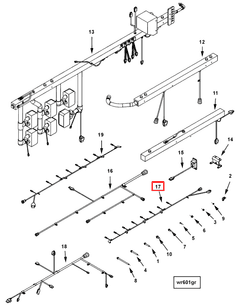

Electronic Control Module Wiring Harness

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4964240 Electronic Control Module (ECM) Wiring Harness by Cummins is a vital component in the operation of commercial trucks. Manufactured by Cummins, a well-established name in the commercial truck industry, this wiring harness is designed to facilitate the communication and power distribution necessary for the truck’s electronic systems to function efficiently 1.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a network of wires and connectors that link the ECM to various sensors, actuators, and other electronic components throughout the truck. This harness ensures that data and power are accurately transmitted between the ECM and the truck’s systems, allowing for precise control and monitoring of engine performance, emissions, and other critical functions 2.

Purpose of the 4964240 Electronic Control Module Wiring Harness

The 4964240 ECM Wiring Harness plays a significant role in the operation of a truck by enabling the ECM to communicate with and control various electronic systems. It ensures that the ECM receives accurate data from sensors and that commands from the ECM are effectively executed by actuators. This interaction is crucial for maintaining optimal engine performance, fuel efficiency, and emissions compliance 3.

Key Features

The 4964240 ECM Wiring Harness is characterized by several key features that enhance its functionality and reliability. These include:

- Durability: Constructed from high-quality materials, the harness is designed to withstand the harsh conditions often encountered in commercial trucking.

- Design: The harness is engineered to fit precisely within the truck’s existing framework, ensuring a secure and efficient installation.

- Integration Capabilities: It is designed to seamlessly integrate with the truck’s electronic systems, facilitating smooth data and power transmission.

Benefits

The implementation of the 4964240 ECM Wiring Harness offers several benefits, including:

- Improved Efficiency: By ensuring accurate and timely data transmission, the harness contributes to more efficient engine operation.

- Reliability: Its robust construction and precise design enhance the reliability of the truck’s electronic systems.

- Performance: The harness supports optimal performance of the ECM and, by extension, the truck’s overall electronic systems.

Installation Process

Installing the 4964240 ECM Wiring Harness involves several steps:

- Preparation: Ensure the truck is turned off and the battery is disconnected to prevent electrical shocks.

- Routing: Carefully route the harness through the truck’s framework, following the manufacturer’s guidelines to avoid damage to the wires.

- Connection: Connect the harness to the ECM and other electronic components, ensuring all connections are secure.

- Testing: After installation, test the harness to confirm that all connections are functioning correctly and that the ECM is receiving accurate data.

Troubleshooting Common Issues

Common issues with the 4964240 ECM Wiring Harness may include:

- Poor Connections: Ensure all connections are secure and free from corrosion.

- Damaged Wires: Inspect the harness for any signs of wear or damage and repair or replace as necessary.

- ECM Malfunction: If the ECM is not functioning correctly, verify that the harness is installed correctly and that all connections are secure.

Maintenance Tips

To ensure the longevity and optimal performance of the 4964240 ECM Wiring Harness, consider the following maintenance tips:

- Regular Inspections: Periodically inspect the harness for signs of wear, damage, or corrosion.

- Cleaning: Keep the harness clean and free from debris to prevent interference with its operation.

- Professional Checks: Have the harness professionally checked during routine maintenance to identify any potential issues early.

Compatibility with Cummins Engines

The Electronic Control Module (ECM) Wiring Harness, part number 4964240, is compatible with various Cummins engines, including the QSK60, CM850, and MCRS engines. This compatibility ensures that the harness can be used interchangeably within these engine groups, providing a standardized solution for maintaining electronic control integrity 4.

Role of 4964240 Electronic Control Module Wiring Harness in Engine Systems

The 4964240 ECM Wiring Harness serves as the vital connective tissue within engine systems, facilitating seamless communication and power distribution between the ECM and various engine components. This harness is meticulously designed to integrate with a multitude of engine components, ensuring optimal performance and reliability.

Integration with Engine Components

-

Sensors: The ECM Wiring Harness connects to an array of sensors such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and Manifold Absolute Pressure (MAP) sensor. These connections allow the ECM to receive real-time data on air intake, exhaust emissions, and engine load, enabling precise control over fuel injection and ignition timing.

-

Actuators: It interfaces with actuators including the fuel injectors, throttle body, and variable valve timing (VVT) solenoids. This ensures that the ECM can dynamically adjust fuel delivery and air intake based on driving conditions and sensor inputs.

-

Ignition System: The harness provides the necessary connections to the ignition coils and spark plugs. This allows the ECM to control the ignition timing with high precision, enhancing engine efficiency and performance.

-

Transmission Control Module (TCM): In engines with automatic transmissions, the ECM Wiring Harness links the ECM with the TCM. This integration enables coordinated control over gear shifting, ensuring smooth transitions and optimal power delivery.

-

Emission Control Systems: It connects to components of the emission control system, such as the Exhaust Gas Recirculation (EGR) valve and the Evaporative Emission Control (EVAP) system. This facilitates the ECM’s role in minimizing harmful emissions while maintaining engine performance.

-

Battery and Alternator: The harness includes connections to the battery and alternator, ensuring that the ECM receives a stable power supply. This is essential for the ECM to operate continuously and maintain engine functions.

-

Grounding Points: Multiple grounding points within the harness ensure that electrical signals are accurately transmitted and received, reducing the risk of electrical noise and ensuring reliable operation of the ECM and connected components.

Conclusion

The 4964240 ECM Wiring Harness by Cummins is a critical component in the efficient and reliable operation of commercial truck engines. Its robust design, precise integration capabilities, and compatibility with various Cummins engines make it an indispensable part of modern engine systems. Regular maintenance and proper installation are essential to ensure the harness functions optimally, contributing to the overall performance and durability of the vehicle.

-

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality (Elsevier, 2021).

↩ -

Tigran Parikyan Ed, Advances in Engine and Powertrain Research and Technology (Springer Nature, 2022).

↩ -

Gang Sheng, Vehicle Noise, Vibration and Sound Quality (SAE International, 2012).

↩ -

P A Lakshminarayanan and Yogesh V Aghav, Modelling Diesel Combustion (Springer Science, 2010).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.