This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5283766 Electrical Connector is a specialized component designed for use in commercial truck operations. This connector facilitates the secure and efficient transmission of electrical signals and power within the truck’s electrical system. Its role is significant as it ensures the reliable operation of various electrical components and systems, contributing to the overall performance and safety of the vehicle 1.

Basic Concepts of Electrical Connectors

Electrical connectors are devices used to join electrical circuits together, allowing the transfer of electrical signals and power between different components. They are integral to the functionality of vehicle electrical systems, ensuring that all electrical components operate correctly and efficiently. The design and quality of these connectors can greatly influence the reliability and performance of the electrical system 2.

Purpose of the 5283766 Electrical Connector

The Cummins 5283766 Electrical Connector serves a specific function within the electrical system of a truck. It is designed to connect various electrical components, ensuring a stable and secure connection that can withstand the rigors of commercial truck operations. This connector plays a role in maintaining the integrity of electrical signals and power distribution, which is vital for the operation of the truck’s electrical systems 3.

Key Features

The Cummins 5283766 Electrical Connector is characterized by several key features that enhance its performance. Its design incorporates robust materials that provide durability and resistance to environmental factors. The connector is engineered to offer a secure fit, minimizing the risk of disconnection or signal interference. Additionally, it features protective elements that safeguard against moisture and debris, ensuring long-term reliability.

Benefits

The advantages of using the Cummins 5283766 Electrical Connector include enhanced reliability, durability, and efficiency in electrical connections. Its design ensures a stable connection, reducing the likelihood of electrical issues that can arise from poor connections. The connector’s materials and construction contribute to its longevity, making it a cost-effective solution for commercial truck applications.

Installation and Usage

Proper installation of the Cummins 5283766 Electrical Connector is crucial for ensuring optimal performance and longevity. It should be installed according to the manufacturer’s guidelines, ensuring a secure and correct fit. Regular checks should be performed to confirm that the connection remains intact and that there are no signs of wear or damage.

Troubleshooting Common Issues

Common problems with electrical connectors can include loose connections, corrosion, or damage to the connector itself. Troubleshooting these issues involves inspecting the connector for signs of wear, ensuring it is securely connected, and cleaning any corrosion that may have formed. In cases of damage, replacement of the connector may be necessary to restore proper function.

Maintenance Tips

Regular maintenance of the Cummins 5283766 Electrical Connector is important for keeping it in good working condition. This includes routine inspections for signs of wear or damage, cleaning the connector to remove any dirt or corrosion, and ensuring that all connections are secure. Following these maintenance practices can help prevent electrical issues and extend the life of the connector.

Safety Considerations

When working with electrical connectors, it is important to follow safety guidelines to prevent accidents and ensure personal safety. This includes wearing appropriate personal protective equipment, ensuring the vehicle’s electrical system is de-energized before working on it, and following proper procedures for installation and maintenance. Adhering to these safety practices helps protect both the individual and the vehicle’s electrical system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins plays a significant role in the commercial truck industry. The company’s products are known for their reliability, efficiency, and performance, making them a preferred choice for commercial vehicle applications.

Cummins Electrical Connector Part 5283766 Compatibility

The Cummins Electrical Connector part number 5283766 is designed to integrate seamlessly with various engine models, ensuring reliable electrical connections and optimal performance. This part is engineered to fit within the Cummins QSM11 and CM570 engine families, providing a critical link in the engine’s electrical system.

Cummins QSM11 Engines

The Cummins QSM11 engines are known for their robust design and efficiency, often used in a variety of industrial and commercial applications. The electrical connector part 5283766 is specifically tailored to meet the needs of these engines, ensuring that all electrical connections are secure and reliable. This part is crucial for maintaining the integrity of the engine’s electrical system, which is essential for the smooth operation of the engine.

Cummins CM570 Engines

Similarly, the Cummins CM570 engines benefit from the use of the electrical connector part 5283766. These engines are typically used in heavy-duty applications, where reliability and performance are paramount. The connector part ensures that all electrical components are properly connected, reducing the risk of electrical failures and enhancing the overall efficiency of the engine.

By using the Cummins Electrical Connector part 5283766, technicians and operators can be confident that their engines will maintain optimal electrical performance, ensuring longevity and reliability in demanding environments.

Role of Part 5283766 Electrical Connector in Engine Systems

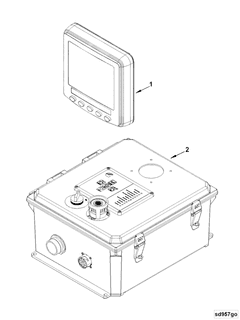

The 5283766 Electrical Connector is integral to the seamless operation of various engine systems. It facilitates the connection between the control panel and the engine instrument system, ensuring that all electrical signals are transmitted accurately and efficiently. This connector is essential for the proper functioning of the engine monitoring system, allowing real-time data to be collected and analyzed.

In the context of product installation, the 5283766 Electrical Connector ensures that all components are correctly linked, reducing the risk of electrical faults and improving overall system reliability. Its role in the package assembly is to provide a secure and consistent electrical interface, which is vital for the durability and performance of the engine system.

Additionally, the connector plays a significant role in the panel integration, where it helps in maintaining the integrity of the electrical connections across different panels. This ensures that the engine instrument system receives consistent and reliable data, which is essential for accurate engine performance monitoring.

Overall, the 5283766 Electrical Connector is a key component in ensuring that all electrical connections within the engine system are robust, reliable, and capable of withstanding the demands of continuous operation.

Conclusion

The Cummins 5283766 Electrical Connector is a vital component in the electrical systems of commercial trucks, particularly those equipped with Cummins QSM11 and CM570 engines. Its robust design, durability, and reliable performance make it an essential part for maintaining the integrity of electrical connections and ensuring the smooth operation of engine systems. Proper installation, regular maintenance, and adherence to safety guidelines are crucial for maximizing the benefits of this connector and ensuring the longevity and reliability of the vehicle’s electrical system.

-

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩ -

Lakshminarayanan, P. A., & Aghav, Y. V. (2010). Modelling Diesel Combustion. Springer Science.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.