This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

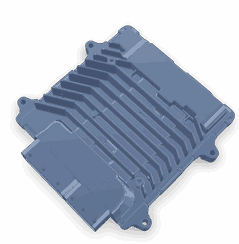

The Cummins 5291535 Electronic Control Module (ECM) is a sophisticated component designed to manage and optimize the operation of commercial trucks. Its purpose is to enhance the efficiency, performance, and reliability of the vehicle by controlling various engine functions. The significance of the ECM in the operation of commercial trucks lies in its ability to integrate and coordinate multiple systems, ensuring that the truck operates at peak performance under a variety of conditions.

Basic Concepts of Electronic Control Modules

An Electronic Control Module (ECM) is a computerized device that plays a central role in the operation of a truck’s systems. It functions by receiving data from various sensors throughout the vehicle, processing this information, and then sending commands to actuators to adjust engine parameters. In modern automotive technology, the ECM is responsible for managing engine operations, optimizing fuel efficiency, controlling emissions, and enhancing overall vehicle performance 1.

Purpose of the 5291535 Electronic Control Module

The Cummins 5291535 ECM is specifically designed to manage the engine’s operations in commercial trucks. It oversees engine management by regulating fuel injection, ignition timing, and other critical parameters to ensure optimal performance. Additionally, the ECM plays a role in emissions control by monitoring and adjusting engine operations to meet environmental regulations. Its responsibilities also extend to enhancing overall vehicle performance by ensuring that the engine operates efficiently under various driving conditions 2.

Key Features

The Cummins 5291535 ECM boasts several key features that contribute to its effectiveness. It is equipped with robust processing power, allowing it to quickly analyze data from multiple sensors and make real-time adjustments to engine operations. The ECM also has a significant memory capacity, enabling it to store diagnostic information and historical data for future reference. Connectivity options, such as CAN (Controller Area Network) bus compatibility, allow the ECM to communicate with other vehicle systems seamlessly. Additionally, the ECM incorporates unique technological advancements, such as advanced algorithms for fuel management and emissions control, enhancing its capabilities 3.

Benefits of Using the 5291535 ECM

The advantages provided by the Cummins 5291535 ECM are numerous. It contributes to improved fuel efficiency by optimizing engine operations, leading to cost savings for fleet operators. Enhanced engine performance is another benefit, as the ECM ensures that the engine operates at its best under various conditions. Better emissions control is achieved through precise management of engine parameters, helping trucks meet stringent environmental regulations. Furthermore, the ECM increases reliability and durability by continuously monitoring and adjusting engine operations to prevent issues and extend the lifespan of the vehicle 4.

Integration with Other Systems

The Cummins 5291535 ECM interacts with other truck systems to provide a cohesive driving experience. It communicates with the transmission to ensure smooth gear changes, works with the braking system to optimize stopping power, and integrates with driver assistance technologies to enhance safety and convenience. This seamless interaction between systems allows for a more efficient and reliable operation of the truck.

Troubleshooting and Maintenance Suggestions

Identifying common issues with the Cummins 5291535 ECM involves monitoring diagnostic trouble codes (DTCs) and performing regular inspections. Diagnostic procedures may include using specialized software to read and interpret DTCs, checking electrical connections, and verifying sensor inputs. Maintenance practices to ensure optimal performance and longevity include keeping the ECM and its connections clean, updating software as needed, and performing regular system checks to identify and address potential issues before they become critical.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation and quality in the automotive industry. The company’s mission is to create technologies that power a more prosperous world, and its contributions to engine and component technology have significantly advanced the capabilities of commercial vehicles.

Future Developments and Innovations

Potential future advancements in ECM technology include the integration of artificial intelligence and machine learning to further optimize engine performance and predict maintenance needs. Trends in automotive electronics suggest a move towards more connected and autonomous vehicles, where ECMs will play a crucial role in managing complex systems. Cummins is well-positioned to lead in this space, leveraging its expertise and commitment to innovation to develop next-generation ECMs that will continue to enhance the performance and efficiency of commercial trucks.

Electronic Control Module (Part 5291535) Compatibility with Cummins Engines

The Electronic Control Module (ECM) part number 5291535, manufactured by Cummins, is a critical component in the operation of several Cummins engine models. This ECM is designed to manage and regulate the engine’s performance, ensuring optimal efficiency and reliability. Below is a detailed description of its compatibility with the specified engines:

ISF2.8 CM2220 F129

The ECM part 5291535 is compatible with the ISF2.8 CM2220 F129 engine. This engine is known for its robust performance and is often used in various industrial applications. The ECM ensures precise control over the engine’s functions, enhancing its operational efficiency and longevity.

ISF3.8 CM2220 AN and ISF3.8 CM2220 F103

The ECM part 5291535 is also suitable for the ISF3.8 CM2220 AN and ISF3.8 CM2220 F103 engines. These engines share a similar architecture and performance characteristics, making the ECM a versatile component across these models. The ECM’s role in these engines is to provide accurate and timely data processing, which is essential for maintaining the engine’s performance under varying conditions.

QSF3.8 CM2880 F112

The ECM part 5291535 is compatible with the QSF3.8 CM2880 F112 engine as well. This engine model is designed for high-performance applications, and the ECM plays a crucial role in managing its complex systems. The ECM’s advanced features ensure that the engine operates at peak efficiency, providing reliable power and reducing downtime.

In summary, the ECM part 5291535 is a critical component for the specified Cummins engines, ensuring optimal performance and reliability across different engine models. Its compatibility with the ISF2.8 CM2220 F129, ISF3.8 CM2220 AN, ISF3.8 CM2220 F103, and QSF3.8 CM2880 F112 engines highlights its versatility and importance in the engine’s operation.

Role of Part 5291535 Electronic Control Module in Engine Systems

The part 5291535 Electronic Control Module (ECM) is integral to the operation of the Engine Control Module (ECM) in various engine systems. This component is responsible for processing data from multiple sensors distributed throughout the engine system.

Sensor Data Integration

The ECM collects inputs from sensors such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, Manifold Absolute Pressure (MAP) sensor, and others. These sensors provide real-time data on air intake, fuel mixture, and exhaust emissions. The ECM uses this data to make precise adjustments to fuel injection timing, ignition timing, and other parameters to optimize engine performance and efficiency.

Actuator Control

Based on the sensor data, the ECM sends commands to various actuators within the engine system. This includes the fuel injectors, ignition coils, and variable valve timing (VVT) systems. By controlling these components, the ECM ensures that the engine operates within specified parameters, enhancing both performance and fuel economy.

Emission Control

The ECM also plays a significant role in emission control. It monitors the data from the O2 sensors and other emission-related sensors to adjust the air-fuel ratio. This ensures that the engine operates in a manner that minimizes harmful emissions, complying with environmental regulations.

Diagnostic Capabilities

In addition to real-time control, the ECM is equipped with diagnostic capabilities. It can detect malfunctions in various engine components by monitoring sensor data and actuator performance. When an issue is detected, the ECM stores diagnostic trouble codes (DTCs), which can be retrieved using an OBD-II scanner for further analysis and repair.

Adaptive Learning

The ECM is designed with adaptive learning algorithms that allow it to adjust to changing conditions over time. This includes adapting to wear and tear on engine components, changes in fuel quality, and variations in driving conditions. By continuously learning and adapting, the ECM maintains optimal engine performance throughout the vehicle’s lifespan.

Communication with Other Modules

The ECM communicates with other control modules in the vehicle, such as the Transmission Control Module (TCM) and the Anti-lock Braking System (ABS) module. This inter-module communication allows for coordinated control of various vehicle systems, enhancing overall drivability and safety.

In summary, the part 5291535 Electronic Control Module is a sophisticated component that integrates sensor data, controls actuators, manages emissions, provides diagnostic capabilities, adapts to changing conditions, and communicates with other vehicle modules to ensure the engine operates efficiently and effectively.

Conclusion

The Cummins 5291535 Electronic Control Module is a critical component in the operation of commercial trucks, designed to optimize engine performance, enhance fuel efficiency, and ensure compliance with emissions regulations. Its advanced features, including robust processing power, significant memory capacity, and connectivity options, make it a versatile and essential part of modern automotive technology. The ECM’s ability to integrate with other vehicle systems and its diagnostic capabilities contribute to the overall reliability and efficiency of commercial trucks. As automotive technology continues to evolve, the role of the ECM will become even more significant, with potential advancements in artificial intelligence and machine learning further enhancing its capabilities.

-

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩ -

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ -

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.