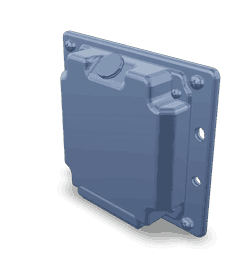

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 5303458 Electronic Interface Module (EIM) is designed to enhance the operation of commercial trucks. It acts as a central hub for communication between various truck systems, ensuring seamless interaction and optimal performance. The significance of this Cummins part lies in its ability to integrate and manage data from different subsystems, contributing to efficient truck operation .

Basic Concepts of Electronic Interface Modules

An Electronic Interface Module (EIM) is a device that facilitates communication between different electronic systems within a vehicle. Its general function is to act as a mediator, allowing various components to share information and operate cohesively. The EIM integrates with other vehicle systems by providing a standardized interface for data exchange, ensuring that all parts of the vehicle can work together effectively .

Role of the 5303458 Electronic Interface Module in Truck Operation

The 5303458 EIM plays a specific role in the operation of a truck by managing the interaction between the engine, transmission, and other critical systems. It collects data from these systems, processes it, and sends appropriate signals to ensure that all components function harmoniously. This module helps in optimizing engine performance, improving transmission efficiency, and enhancing overall truck operation .

Key Features of the 5303458 Electronic Interface Module

The primary features of the 5303458 EIM include robust connectivity options, advanced diagnostic capabilities, and seamless integration with Cummins software. These features allow for comprehensive monitoring and control of the truck’s systems, providing real-time data and insights that can be used to maintain and optimize performance.

Benefits of Using the 5303458 Electronic Interface Module

The advantages provided by the 5303458 EIM include improved diagnostics, which allow for quicker identification and resolution of issues. Enhanced performance monitoring enables operators to keep track of the truck’s condition in real-time, leading to better maintenance practices. Additionally, the increased reliability offered by the EIM contributes to reduced downtime and improved fleet efficiency.

Installation and Integration

When installing and integrating the 5303458 EIM into a truck’s system, it is important to follow specific guidelines and considerations. This may include ensuring that the necessary software and hardware requirements are met, as well as properly connecting the EIM to the truck’s existing systems. Careful attention to these details will help ensure that the EIM functions correctly and provides the intended benefits.

Troubleshooting Common Issues

To address common problems that may arise with the 5303458 EIM, it is helpful to follow a systematic approach. This includes identifying error codes, checking for connectivity issues, and addressing any performance anomalies. By taking these steps, operators can often resolve issues quickly and keep the truck running smoothly.

Maintenance and Care

Maintaining the 5303458 EIM involves regular checks, software updates, and physical inspections. These practices help ensure that the module continues to operate optimally. By staying on top of maintenance, operators can prevent many common issues and extend the lifespan of the EIM.

Impact on Fleet Operations

The 5303458 EIM can have a notable impact on fleet operations by influencing maintenance schedules, driver training, and overall fleet efficiency. Its ability to provide real-time data and diagnostics allows for more informed decision-making, leading to better fleet management and performance.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the automotive industry, known for its innovative products and commitment to quality. With a rich history and a diverse product range, Cummins continues to push the boundaries of technology, providing solutions that enhance the performance and reliability of commercial vehicles.

Role of the Electronic Interface Module (Part 5303458) in Engine Systems

The Electronic Interface Module (Part 5303458) serves as a pivotal component in the orchestration of various engine systems. It acts as the central hub for communication between the engine control unit (ECU) and other electronic components, ensuring seamless data exchange and coordinated operation.

Integration with Key Engine Components

-

Engine Control Unit (ECU): The Electronic Interface Module facilitates real-time data transfer between the ECU and other engine subsystems. This ensures that the ECU receives accurate sensor readings and can make precise adjustments to fuel injection, ignition timing, and other critical parameters.

-

Sensors: Various sensors, such as the mass airflow sensor, oxygen sensor, and throttle position sensor, relay vital data to the Electronic Interface Module. This module then processes the information and transmits it to the ECU for analysis and decision-making.

-

Actuators: The module also interfaces with actuators, including the fuel injectors, idle air control valve, and variable valve timing solenoids. It sends commands from the ECU to these components, ensuring they operate in harmony with the engine’s requirements.

-

Diagnostic Systems: In conjunction with the onboard diagnostics (OBD) system, the Electronic Interface Module helps in monitoring the health of engine components. It collects data that can be used for fault detection and reporting, aiding in proactive maintenance.

-

Communication Networks: The module is integral to the engine’s communication network, often part of the controller area network (CAN) bus. It ensures that all electronic components are synchronized and can share information efficiently.

-

User Interface: For engines equipped with a driver information system, the Electronic Interface Module may also relay data to the vehicle’s dashboard, providing real-time feedback on engine performance and status.

By bridging the gap between disparate engine components, the Electronic Interface Module (Part 5303458) enhances the overall efficiency, performance, and reliability of the engine system.

Conclusion

The Cummins 5303458 Electronic Interface Module is a vital component in the operation of commercial trucks and engines. Its role in facilitating communication between various systems, providing advanced diagnostics, and enhancing overall performance makes it an indispensable part of modern vehicle technology. Proper installation, maintenance, and troubleshooting are essential to ensure the module functions optimally, contributing to improved fleet efficiency and reliability.

: Khajepour, A. (2023). *Synthesis Lectures on Advances in Automotive Technology*. Springer.

: Randall, M. (2015). *Haynes Manual on Diesel Engines*. Haynes Publishing.

: Hick, H., Kupper, K., & Sorger, H. (2021). *Systems Engineering for Automotive Powertrain Development*. Springer.SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.