This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

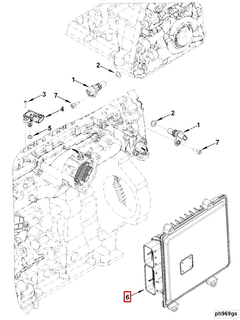

The 5306852 Electronic Control Module (ECM) by Cummins is a sophisticated component designed to enhance the operation of commercial trucks. It plays a role in optimizing engine performance and efficiency, contributing to the overall effectiveness of the vehicle.

Basic Concepts of Electronic Control Modules

An Electronic Control Module (ECM) is a vital component within a truck’s engine management system. It functions by processing data from various sensors throughout the engine and making real-time adjustments to optimize performance. The ECM operates on basic principles of data acquisition, processing, and control, ensuring that the engine runs efficiently under varying conditions 1.

Purpose of the 5306852 ECM

The 5306852 ECM is specifically designed to manage and control various aspects of a truck’s engine. Its responsibilities include regulating fuel injection, monitoring engine parameters, and ensuring compliance with emissions standards. By optimizing these functions, the ECM contributes to improved engine performance and reduced environmental impact 2.

Key Features

The 5306852 ECM boasts several key features that enhance its functionality. These include advanced diagnostics capabilities, which allow for real-time monitoring and troubleshooting of engine issues. Additionally, the ECM processes data in real-time, enabling quick responses to changing conditions. It also integrates seamlessly with other vehicle systems, providing a comprehensive approach to engine management 3.

Benefits of Using the 5306852 ECM

Incorporating the 5306852 ECM into a truck’s engine management system offers numerous benefits. These include improved fuel efficiency, which can lead to cost savings over time. The ECM also enhances engine performance by ensuring optimal operation under various conditions. Furthermore, it helps in reducing emissions, contributing to a cleaner environment. Increased reliability is another advantage, as the ECM’s advanced diagnostics and real-time adjustments help prevent potential issues before they become critical 1.

Installation and Integration

Proper installation and integration of the 5306852 ECM are crucial for its effective operation. This process involves connecting the ECM to the truck’s engine management system through appropriate wiring. Software updates may be necessary to ensure compatibility and optimal performance. Calibration procedures might also be required to fine-tune the ECM’s settings for the specific engine it is controlling 4.

Troubleshooting and Maintenance

To maintain the 5306852 ECM’s performance, it is important to follow troubleshooting and maintenance practices. Common issues can often be diagnosed using the ECM’s built-in diagnostic tools, which provide error codes that can guide repair efforts. Regular maintenance, such as software updates and sensor checks, ensures that the ECM continues to operate efficiently 2.

Impact on Fleet Operations

The introduction of the 5306852 ECM into fleet operations can have significant implications. Fleet managers and operators may need to adjust maintenance schedules to accommodate the ECM’s diagnostic capabilities and real-time data processing. Performance monitoring becomes more streamlined, allowing for proactive management of engine health. Additionally, the cost-effectiveness of the fleet can be enhanced through improved fuel efficiency and reduced emissions 3.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its innovative engine technologies and comprehensive product offerings. With a rich history of providing reliable and high-performance engines, Cummins has built a strong reputation for quality and durability. The company’s commitment to advancing engine technology is evident in products like the 5306852 ECM, which exemplifies Cummins’ dedication to enhancing engine performance and efficiency 4.

Electronic Control Module (Part 5306852) Compatibility with Cummins Engines

The Electronic Control Module (ECM) part number 5306852, manufactured by Cummins, is a critical component for the operation of several engine models. This ECM is designed to manage and regulate various engine functions, ensuring optimal performance and efficiency. Below is a detailed description of its compatibility with the specified engines:

QSF2.8 CM2880 Series

The ECM part 5306852 is compatible with the following engines within the QSF2.8 CM2880 series:

- QSF2.8 CM2880 F104

- QSF2.8 CM2880 F105

- QSF2.8 CM2880 F108

These engines share a common architecture and control system, making the ECM part 5306852 a suitable fit for all three models. The ECM interfaces with the engine’s sensors and actuators to monitor and adjust parameters such as fuel injection timing, air intake, and exhaust emissions.

QSF3.8 CM2880 Series

The ECM part 5306852 is also compatible with the following engine:

- QSF3.8 CM2880 F112

While this engine belongs to a slightly different series, it shares many similarities with the QSF2.8 CM2880 series in terms of control architecture. The ECM part 5306852 is designed to work seamlessly with the QSF3.8 CM2880 F112, ensuring that it can manage the engine’s functions effectively.

Summary

The ECM part 5306852 is a versatile and essential component for the specified Cummins engines. Its compatibility with both the QSF2.8 CM2880 and QSF3.8 CM2880 series underscores its importance in maintaining engine performance and efficiency across different models.

Conclusion

The 5306852 ECM is a pivotal component that ensures the seamless integration and operation of various engine systems, contributing to overall engine efficiency, performance, and emissions compliance. Its advanced features and benefits make it a valuable addition to any commercial truck’s engine management system.

-

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ ↩ -

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ ↩ -

Stone, R. (2012). Introduction to Internal Combustion Engines, Fourth Edition. Macmillan.

↩ ↩ -

Cummins Inc. (n.d.). Owners Manual for QSB3.3 CM2250 B137. Bulletin Number 5411060.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.