This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

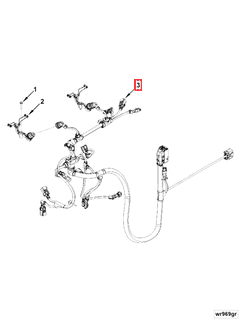

The Electronic Control Module Wiring Assembly (part number 5316891) by Cummins is a specialized component designed for use in commercial trucks. This assembly facilitates communication between the Electronic Control Module (ECM) and various electronic systems within the truck. Its purpose is to ensure reliable and efficient operation of the truck’s electronic systems, contributing to overall vehicle performance and reliability.

Basic Concepts

Electronic Control Module Wiring Assemblies are integral to the truck’s electronic system. They serve as the conduit for signals between the ECM and other electronic components, such as sensors, actuators, and control units. These assemblies are responsible for transmitting data and power, enabling the ECM to monitor and control various functions within the truck. Understanding the role of these wiring assemblies is fundamental to grasping how modern trucks operate electronically 1.

Purpose and Role

The 5316891 Electronic Control Module Wiring Assembly is designed to connect the ECM to the truck’s electronic systems. It plays a role in facilitating communication and power distribution between the ECM and other components. This assembly ensures that the ECM can effectively manage engine performance, transmission operations, and various other systems by providing a reliable pathway for data and electrical signals 2.

Key Features

The 5316891 Electronic Control Module Wiring Assembly is characterized by its robust design and high-quality materials. It is engineered to withstand the harsh conditions typically encountered in commercial truck environments. Key features include corrosion-resistant connectors, durable insulation, and a compact design that facilitates easy installation and integration into the truck’s electronic system. These features contribute to the assembly’s performance and reliability 3.

Benefits

The integration of the 5316891 Electronic Control Module Wiring Assembly into a truck’s electronic system offers several benefits. It contributes to improved engine performance by ensuring efficient communication between the ECM and engine components. Additionally, it enhances diagnostic capabilities, allowing for more accurate monitoring and troubleshooting of the truck’s electronic systems. Furthermore, it increases the overall efficiency of the truck’s electronic systems, leading to better fuel economy and reduced maintenance costs 2.

Installation and Integration

When installing the 5316891 Electronic Control Module Wiring Assembly, it is important to follow manufacturer guidelines to ensure proper integration into the truck’s electronic system. Compatibility with various truck models and ECMs should be verified prior to installation. Careful attention to detail during the installation process will help ensure that the assembly functions as intended, contributing to the truck’s overall performance and reliability 3.

Troubleshooting and Maintenance

To maintain the performance and longevity of the 5316891 Electronic Control Module Wiring Assembly, regular inspection and maintenance are recommended. Common issues may include corroded connectors or damaged insulation, which can be addressed through cleaning or replacement as necessary. Adhering to best practices for troubleshooting and maintenance will help ensure that the assembly continues to operate efficiently, contributing to the truck’s overall reliability 2.

Cummins Overview

Cummins is a renowned manufacturer with a long-standing reputation in the automotive and heavy-duty truck industries. The company is committed to producing high-quality components that meet the demanding requirements of commercial truck applications. Cummins’ focus on innovation, quality, and customer satisfaction has established it as a trusted name in the industry, providing reliable solutions for enhancing truck performance and efficiency 3.

Electronic Control Module Wiring Assembly for Cummins Engines

The Electronic Control Module (ECM) Wiring Assembly, part number 5316891, is a critical component for the proper functioning of various Cummins engines. This assembly ensures that the ECM can communicate effectively with other engine control units and sensors, facilitating optimal engine performance and efficiency.

ISF3.8 CM2220 AN

For the ISF3.8 CM2220 AN engine, the ECM Wiring Assembly is integral to the engine’s electronic control system. This assembly connects the ECM to various sensors and actuators, ensuring that the engine can monitor and adjust its performance parameters in real-time. The wiring harness is designed to withstand the harsh conditions within the engine compartment, providing reliable connectivity and minimizing the risk of electrical faults.

The ECM Wiring Assembly for the ISF3.8 CM2220 AN engine is engineered to meet the specific electrical requirements of this engine model. It includes connectors and wiring that are tailored to the unique layout and configuration of the engine’s electronic control system. This ensures that the ECM can accurately receive and process data from the engine’s sensors, allowing for precise control of fuel injection, ignition timing, and other critical functions.

By integrating seamlessly with the engine’s electronic architecture, the ECM Wiring Assembly plays a vital role in maintaining the reliability and performance of the ISF3.8 CM2220 AN engine. Its design and construction reflect Cummins’ commitment to quality and durability, ensuring that the engine can operate efficiently and reliably over its service life 4.

Role of Part 5316891 Electronic Control Module Wiring Assembly in Engine Systems

The Electronic Control Module (ECM) Wiring Assembly, identified by part number 5316891, is integral to the operation of modern engine systems. This assembly serves as the vital link between the ECM and various engine components, facilitating the transmission of data and control signals necessary for optimal engine performance.

Integration with the Harness

The ECM Wiring Assembly interfaces directly with the vehicle’s wiring harness. This connection ensures that the ECM receives accurate data from sensors distributed throughout the engine system. The harness, in turn, relies on the ECM Wiring Assembly to transmit control signals to actuators, such as fuel injectors and ignition coils, enabling precise management of fuel delivery and ignition timing.

Communication with the Electronic Control Module

At the heart of the engine management system, the ECM relies on the ECM Wiring Assembly to communicate with all connected components. This assembly ensures that the ECM can monitor engine parameters in real-time, such as engine temperature, air-fuel ratio, and throttle position. By providing a robust and reliable connection, the ECM Wiring Assembly allows the ECM to make instantaneous adjustments to engine operation, enhancing efficiency and performance.

Ensuring System Integrity

The ECM Wiring Assembly plays a significant role in maintaining the integrity of the engine management system. It is designed to withstand the harsh environment under the hood, protecting sensitive electronic components from heat, vibration, and electrical interference. This durability ensures that the ECM can continue to operate effectively, even under demanding conditions.

Facilitating Diagnostic Capabilities

Modern engine systems are equipped with advanced diagnostic capabilities, allowing mechanics to quickly identify and address issues. The ECM Wiring Assembly is essential for these diagnostic functions, providing a clear pathway for data to flow between the ECM and diagnostic tools. This facilitates efficient troubleshooting and maintenance, reducing downtime and improving overall vehicle reliability.

Conclusion

The ECM Wiring Assembly (part 5316891) is a fundamental component in the engine management system, ensuring seamless communication between the ECM, wiring harness, and various engine components. Its role in data transmission, system integrity, and diagnostic capabilities underscores its importance in maintaining optimal engine performance.

-

Reif, Konrad. Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer, 2014.

↩ -

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩ ↩ ↩ -

Hilgers, Michael. Vocational Vehicles and Applications. Springer Nature, 2023.

↩ ↩ ↩ -

Cummins Inc. Service Manual (5579689). L9 CM2350 L129C.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.