This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

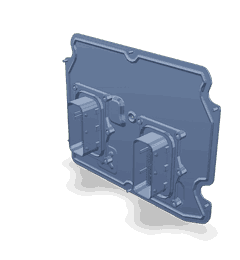

The Cummins 5317106 Electronic Control Module (ECM) is a sophisticated component designed to manage and optimize the performance of commercial trucks. This ECM is integral to the operation of Cummins engines, ensuring efficient and reliable performance. Its significance lies in its ability to enhance engine management, control emissions, and contribute to overall vehicle performance 1.

Basic Concepts of Electronic Control Modules

An Electronic Control Module (ECM) is a computerized device that plays a central role in the management of vehicle systems. It processes data from various sensors and actuators to control engine functions, transmission operations, and other critical systems. The ECM is part of the vehicle’s management system, which includes the engine control unit (ECU), transmission control unit (TCU), and other control modules. These systems work together to ensure the vehicle operates efficiently and reliably 2.

Purpose of the Cummins 5317106 Electronic Control Module

The Cummins 5317106 ECM is specifically designed to manage the engine’s operations in commercial trucks. It oversees engine management by regulating fuel injection, ignition timing, and other parameters to ensure optimal performance. Additionally, it plays a role in emissions control by monitoring and adjusting engine operations to meet environmental regulations. The ECM also contributes to overall vehicle performance by coordinating with other systems to provide a smooth and efficient driving experience 3.

Key Features

The Cummins 5317106 ECM boasts several key features that enhance its functionality. These include advanced processing capabilities, substantial memory storage for data logging and diagnostics, and multiple communication interfaces for interaction with other vehicle systems. The ECM also incorporates unique technological advancements, such as improved algorithms and machine learning capabilities, to provide precise control and adaptive performance.

Benefits of Using the Cummins 5317106 ECM

Utilizing the Cummins 5317106 ECM offers several advantages. It contributes to improved engine performance by ensuring precise control over engine operations. Enhanced fuel efficiency is another benefit, as the ECM optimizes fuel delivery and combustion processes. Better emissions control is achieved through real-time monitoring and adjustment of engine parameters. Additionally, the ECM increases reliability and durability by providing consistent and accurate control, reducing the likelihood of mechanical issues.

Integration with Other Systems

The Cummins 5317106 ECM interacts seamlessly with other truck systems to provide a cohesive driving experience. It communicates with the transmission system to ensure smooth gear changes and optimal power delivery. The ECM also works with the braking system to enhance safety and performance. Furthermore, it interfaces with driver information displays to provide real-time data and diagnostics, allowing drivers to monitor vehicle performance and make informed decisions.

Diagnostic and Monitoring Capabilities

The Cummins 5317106 ECM is equipped with robust diagnostic and monitoring features. It can store error codes and provide real-time data on engine performance, allowing for quick identification and resolution of issues. The ECM also supports remote diagnostics, enabling technicians to monitor and diagnose problems without physical access to the vehicle. This capability enhances maintenance efficiency and reduces downtime.

Troubleshooting and Maintenance Suggestions

To troubleshoot common issues with the Cummins 5317106 ECM, it is important to follow a systematic approach. Begin by checking for error codes stored in the ECM and referring to the manufacturer’s diagnostic guidelines. Regular maintenance practices, such as updating software, inspecting connections, and performing routine checks, can help ensure the ECM’s longevity and optimal performance. Additionally, keeping the ECM and its components clean and free from corrosion will contribute to its reliability.

Technological Advancements

The Cummins 5317106 ECM incorporates several technological innovations. Advanced algorithms and machine learning capabilities allow the ECM to adapt to changing conditions and optimize performance over time. Integration with IoT (Internet of Things) enhances fleet management by providing real-time data and insights into vehicle operations. These advancements contribute to improved efficiency, reliability, and overall performance.

Environmental Impact

The Cummins 5317106 ECM plays a role in reducing the environmental impact of commercial trucks. By precisely controlling engine operations, it helps achieve better emissions control, meeting stringent environmental regulations. Improved fuel efficiency also contributes to lower greenhouse gas emissions, making commercial trucking more sustainable. The ECM’s ability to optimize engine performance further supports these environmental benefits.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established itself as a trusted name in the commercial truck industry. The company’s mission is to power a more prosperous world, and its commitment to innovation and customer satisfaction is evident in products like the Cummins 5317106 ECM.

Cummins Electronic Control Module (ECM) 5317106 Compatibility

The Cummins Electronic Control Module (ECM) part number 5317106 is a critical component for the operation of various Cummins diesel engines. This ECM is designed to manage and control the engine’s performance, ensuring optimal efficiency and reliability. Below is a detailed overview of the engines with which this ECM is compatible:

B Series Engines

- B4.5 CM2350 B104

- B6.7 CM2350 B101

- B6.7 CM2350 B105

F Series Engines

- F3.8 CM2350 F109

- F3.8 CM2350 F120B

- F3.8 CM2350 F128C

- F3.8 CM2350 F107

I Series Engines

- ISB4.5 CM2350 B104

- ISB6.7 CM2350 B101

- ISF3.8 CM2350 F109

QSB Series Engines

- QSB6.7 CM2350 B105

- QSF3.8 CM2350 F107

- QSL9 CM2350 L102

- QST30 CM2350 T101

QSK Series Engines

- QSK19 CM2350 K105

- QSK19 CM2350 K114

- QSK19 CM2350 K144G

- QSK50 CM2350 K108

- QSK95 CM2350 K111

- QSK95 CM2350 K113

ISX Series Engines

- ISX12 CM2350 X102

- ISX15 CM2350 X101

X Series Engines

- X12 CM2350 X119B

- X12 CM2670 X121B

Other Series Engines

- B129B

- B152B

- B135B

- G107

- G110

- X105

The ECM 5317106 is engineered to work seamlessly with these engines, providing precise control over various engine functions, including fuel injection, timing, and emissions management. Its compatibility with a wide range of Cummins engines underscores its versatility and importance in maintaining engine performance across different applications.

Role of Part 5317106 Electronic Control Module in Engine Systems

The Electronic Control Module (ECM) part 5317106 is integral to the operation and management of various engine systems. It acts as the central processing unit for the engine, coordinating and optimizing the performance of multiple components.

Integration with Engine Control Module (ECM)

The ECM 5317106 interfaces directly with the Engine Control Module to manage engine operations. It processes data from various sensors and adjusts engine parameters such as fuel injection timing, ignition timing, and valve timing to ensure optimal performance and efficiency.

Coordination with Fuel Control Module

In conjunction with the Fuel Control Module, the ECM 5317106 regulates fuel delivery. It monitors fuel pressure, flow rate, and air-fuel ratio, making real-time adjustments to maintain efficient combustion and reduce emissions.

Electronic Service Calibration

The ECM 5317106 is also responsible for Electronic Service Calibration. It stores calibration data that can be updated or modified to adapt to different operating conditions or to comply with updated emissions standards. This ensures the engine maintains peak performance throughout its operational life.

Sensor Data Processing

The ECM 5317106 collects data from various sensors such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensor, and Manifold Absolute Pressure (MAP) sensor. It uses this data to make informed decisions about engine operation, ensuring that all systems work in harmony.

Actuator Control

The ECM 5317106 controls various actuators within the engine system, including the throttle body, fuel injectors, and variable valve timing mechanisms. By precisely controlling these components, it ensures that the engine operates smoothly and efficiently under all conditions.

Fault Detection and Diagnostics

One of the key functions of the ECM 5317106 is to monitor the engine for faults. It continuously checks the performance of various components and systems, logging any irregularities or malfunctions. This data is invaluable for diagnostics, allowing mechanics to quickly identify and address issues.

Communication with Other Systems

The ECM 5317106 also communicates with other vehicle systems, such as the transmission control module and the anti-lock braking system (ABS). This inter-system communication allows for coordinated vehicle performance, enhancing both safety and efficiency.

Conclusion

The Cummins 5317106 Electronic Control Module is a vital component in the management and optimization of commercial truck engines. Its advanced features, integration with other systems, and diagnostic capabilities make it an essential part of modern engine management systems. By ensuring precise control over engine operations, the ECM contributes to improved performance, fuel efficiency, and emissions control, ultimately enhancing the overall driving experience and environmental sustainability.

-

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩ -

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.