This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

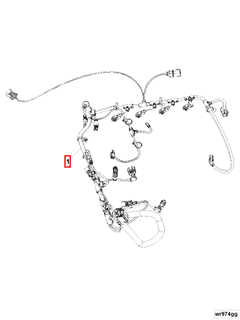

The Cummins 5342591 Electronic Control Module Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a vital link in the vehicle’s electrical system, facilitating communication and power distribution between the electronic control module (ECM) and various electronic systems within the truck. This harness is engineered to ensure reliable operation and efficient performance of the truck’s electronic systems.

Basic Concepts

Electronic control module wiring harnesses are integral to a vehicle’s electrical system. They consist of a network of wires, connectors, and terminals that transmit electrical signals and power between the ECM and other electronic components. These harnesses enable the ECM to monitor and control various functions of the truck, such as engine performance, transmission operation, and emissions control. Understanding the function and interaction of these harnesses with other components is fundamental to maintaining and troubleshooting the truck’s electrical system 1.

Purpose and Function

The Cummins 5342591 Electronic Control Module Wiring Harness is designed to connect the ECM to the truck’s electronic systems. It plays a role in transmitting data and power, allowing the ECM to effectively manage and regulate the truck’s operations. This harness ensures that the ECM receives accurate information from sensors and other components, enabling it to make precise adjustments to the truck’s performance. Additionally, it distributes power to various electronic systems, ensuring they operate efficiently 2.

Key Features

The Cummins 5342591 Electronic Control Module Wiring Harness is characterized by its robust design and high-quality construction materials. It is built to withstand the demanding conditions of commercial truck operations, including exposure to vibrations, temperature fluctuations, and moisture. The harness features durable connectors and terminals that ensure secure and reliable connections. Its design also includes protective measures to prevent damage from electrical interference and physical stress, enhancing its performance and longevity 3.

Benefits

The use of the Cummins 5342591 Electronic Control Module Wiring Harness offers several benefits to fleet operators. It contributes to improved reliability by ensuring consistent and accurate communication between the ECM and other electronic systems. This results in enhanced performance of the truck, as the ECM can make real-time adjustments based on precise data. Additionally, the harness can lead to potential cost savings by reducing the likelihood of electrical malfunctions and the need for frequent repairs 4.

Installation and Integration

Proper installation and integration of the Cummins 5342591 Electronic Control Module Wiring Harness are vital to ensure its effective operation within the truck’s electrical system. It is important to follow manufacturer guidelines and consider compatibility with various truck models and ECMs. Careful attention to detail during installation helps prevent issues such as loose connections or damage to the harness, which could affect the truck’s performance .

Troubleshooting and Maintenance

Regular maintenance and prompt troubleshooting of the Cummins 5342591 Electronic Control Module Wiring Harness are important for ensuring optimal performance and longevity. Common issues may include loose connections, damaged wires, or faulty terminals. Best practices for maintenance include periodic inspections for signs of wear or damage, ensuring all connections are secure, and protecting the harness from physical stress and environmental factors. Addressing issues promptly can prevent more significant problems and ensure the harness continues to function effectively .

Safety Considerations

When working with the Cummins 5342591 Electronic Control Module Wiring Harness, it is important to observe safety considerations and precautions. This includes proper handling, installation, and maintenance procedures to minimize the risk of electrical hazards or malfunctions. Ensuring that the electrical system is de-energized before performing any work on the harness is a fundamental safety practice. Additionally, using the appropriate tools and following manufacturer guidelines can help prevent accidents and ensure the safe operation of the truck’s electrical system .

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a strong reputation in the industry, Cummins is committed to quality and excellence in the production of automotive components. The company’s dedication to research and development ensures that its products, including the Cummins 5342591 Electronic Control Module Wiring Harness, meet the high standards required for commercial truck applications .

Conclusion

The Cummins 5342591 Electronic Control Module Wiring Harness is a critical component in the electrical system of commercial trucks. Its robust design, key features, and benefits contribute to the reliable operation and efficient performance of the truck’s electronic systems. Proper installation, regular maintenance, and adherence to safety considerations are essential for maximizing the harness’s performance and longevity. Cummins’ commitment to quality and innovation ensures that this part meets the high standards required for commercial truck applications.

-

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Fehan, D. R. (2013). Design of Racing and High-Performance Engines 2004-2013. SAE International.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4332681.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.