5372678

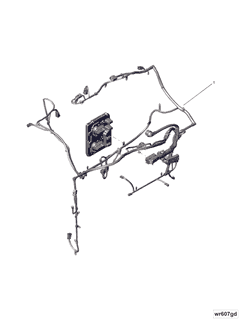

Electronic Control Module Wiring Harness

Cummins®

IN STOCK

1 is currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5372678 Electronic Control Module Wiring Harness is a component manufactured by Cummins, a well-established name in the automotive industry. This wiring harness plays a significant role in the operation of commercial trucks by facilitating the communication between the Electronic Control Module (ECM) and various sensors and actuators within the vehicle.

Basic Concepts

Understanding the fundamental concepts related to Electronic Control Module Wiring Harnesses is important for grasping their function and integration within a truck’s electronic system. These harnesses consist of a network of wires, connectors, and terminals designed to transmit electrical signals. They are integral to the truck’s electronic system, enabling the ECM to receive data from sensors and send commands to actuators, thereby controlling various aspects of the truck’s operation 2.

Purpose and Functionality

The 5372678 Electronic Control Module Wiring Harness serves the purpose of establishing a reliable communication pathway between the ECM and the truck’s sensors and actuators. This communication is vital for the ECM to monitor and adjust the truck’s performance in real-time. The harness allows the ECM to receive input from sensors regarding engine conditions, vehicle speed, and other operational parameters. Based on this input, the ECM sends signals through the harness to actuators, which then make the necessary adjustments to optimize the truck’s performance 4.

Key Features

The 5372678 Wiring Harness is characterized by several key features that enhance its performance and reliability. Its design incorporates high-quality materials that are resistant to wear, corrosion, and environmental factors. The harness is engineered for durability, ensuring it can withstand the rigors of commercial truck operation. Additionally, it features precise connectors and terminals that ensure secure and reliable connections, minimizing the risk of signal interference or loss 1.

Benefits

Utilizing the 5372678 Wiring Harness offers several benefits to commercial truck operators. It contributes to improved engine performance by ensuring accurate and timely communication between the ECM and the truck’s components. This results in enhanced fuel efficiency, as the ECM can make precise adjustments to optimize fuel consumption. Furthermore, the harness aids in reducing emissions by enabling the ECM to control emissions-related systems more effectively. Its reliable performance also increases the overall reliability of the truck’s electronic systems, leading to fewer breakdowns and maintenance issues 3.

Installation and Integration

Proper installation and integration of the 5372678 Wiring Harness within a truck’s electronic system are crucial for optimal performance. It is important to follow guidelines and best practices during installation to ensure the harness is correctly routed, secured, and connected. This includes handling the harness with care to avoid damage to the wires and connectors, as well as ensuring all connections are tight and secure. Proper installation not only enhances the performance of the harness but also contributes to the overall reliability of the truck’s electronic system 2.

Troubleshooting and Maintenance

Regular maintenance and troubleshooting are important for ensuring the longevity and reliability of the 5372678 Wiring Harness. Common issues may include wear, corrosion, or damage to the wires or connectors. Inspecting the harness for these issues during routine maintenance can help identify problems early, allowing for timely repairs or replacements. Additionally, following manufacturer guidelines for maintenance and troubleshooting can help prevent issues and ensure the harness continues to perform reliably 3.

Safety Considerations

When working with the 5372678 Wiring Harness, it is important to observe safety considerations to protect both the technician and the equipment. This includes following proper handling procedures to avoid damage to the harness, as well as adhering to electrical safety precautions to prevent electrical shocks or fires. It is also important to follow manufacturer guidelines for installation, maintenance, and troubleshooting to ensure the harness operates safely and reliably 3.

Cummins Overview

Cummins Inc. is a reputable manufacturer in the automotive industry, known for its commitment to producing high-quality components. With a rich history of innovation and excellence, Cummins has established itself as a leader in the production of engines, powertrains, and related components. The company’s dedication to quality and performance is evident in its products, including the 5372678 Electronic Control Module Wiring Harness, which is designed to meet the demanding requirements of commercial truck operations 4.

Electronic Control Module Wiring Harness for Cummins Engines

The Electronic Control Module (ECM) Wiring Harness, part number 5372678, is a critical component in the Cummins engine ecosystem. This wiring harness is designed to facilitate seamless communication between the ECM and various engine sensors and actuators. It ensures that the ECM can effectively monitor and control engine performance, emissions, and overall functionality.

Application in Cummins Engines

The ECM Wiring Harness is integral to the proper operation of several Cummins engines, including the QSK38 CM2150 MCRS and QSK60 CM850 MCRS. These engines are part of the Cummins QSK series, known for their reliability and efficiency in a variety of applications, from marine to industrial use.

QSK38 CM2150 MCRS

In the QSK38 CM2150 MCRS engine, the ECM Wiring Harness connects the ECM to critical components such as the fuel injection system, turbocharger, and exhaust gas recirculation (EGR) system. This ensures that the engine can dynamically adjust to varying loads and operating conditions, maintaining optimal performance and fuel efficiency.

QSK60 CM850 MCRS

Similarly, in the QSK60 CM850 MCRS engine, the ECM Wiring Harness plays a pivotal role in linking the ECM with the engine’s sensors and actuators. This includes connections to the fuel injectors, variable geometry turbocharger, and other critical systems. The harness ensures that the ECM can accurately interpret sensor data and make real-time adjustments to engine parameters, enhancing both performance and emissions control.

Importance of the Wiring Harness

The ECM Wiring Harness is essential for maintaining the integrity of the engine’s electronic control systems. It must be properly installed and maintained to prevent issues such as poor engine performance, increased emissions, and potential engine failures. Regular inspection and maintenance of the wiring harness can help prevent these issues, ensuring that the engine operates at peak efficiency.

By ensuring that the ECM can communicate effectively with the engine’s various components, the ECM Wiring Harness is a key factor in the overall reliability and performance of the Cummins QSK38 CM2150 MCRS and QSK60 CM850 MCRS engines.

Role of Part 5372678 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified by part number 5372678, is integral to the operation of modern engine systems. This harness serves as the vital link between the ECM and various engine components, facilitating the transmission of electrical signals that are essential for engine management and performance.

Integration with Engine Components

-

Sensors: The ECM Wiring Harness connects to a multitude of sensors distributed throughout the engine system. These sensors monitor parameters such as temperature, pressure, and airflow. The harness ensures that real-time data is accurately transmitted to the ECM, allowing for precise control over engine operations.

-

Actuators: Actuators, which include components like fuel injectors, ignition coils, and variable valve timing solenoids, rely on the ECM Wiring Harness to receive commands from the ECM. This communication is essential for the actuators to perform their functions, such as injecting fuel at the correct time or adjusting valve timing for optimal performance.

-

Power Supply: The harness also plays a role in distributing power from the vehicle’s electrical system to the ECM and other electronic components. This ensures that all parts of the engine system have the necessary electrical power to operate efficiently.

-

Grounding: Proper grounding is facilitated by the ECM Wiring Harness, which connects various components to the vehicle’s chassis. This grounding is essential for the stable operation of electronic components and helps in reducing electrical noise that could interfere with signal transmission.

-

Communication Networks: In many modern vehicles, the ECM Wiring Harness is part of a larger communication network that includes other control modules (such as the transmission control module or the anti-lock braking system module). This network allows for coordinated control of various vehicle systems, enhancing overall performance and safety.

Operational Significance

The ECM Wiring Harness is designed to withstand the harsh environment of the engine compartment, including exposure to heat, vibration, and chemicals. Its robust construction ensures reliable operation under all driving conditions, contributing to the durability and efficiency of the engine system.

Conclusion

In summary, the ECM Wiring Harness (part 5372678) is a fundamental component that enables the ECM to effectively manage and control the engine system. Its role in connecting sensors, actuators, and other components is essential for the precise and efficient operation of modern engines. Proper installation, maintenance, and understanding of its functionality are crucial for ensuring the reliability and performance of commercial trucks equipped with Cummins engines.

-

P A Lakshminarayanan and Yogesh V Aghav, Modelling Diesel Combustion (Springer Science, 2010)

↩ -

Haoran Hu, Rudy Smaling, and Simon Baseley, Heavy-Duty Wheeled Vehicles (SAE International, 2014)

↩ ↩ -

Cummins Inc., Fault Code Troubleshooting Manual, Bulletin Number 5659678

↩ ↩ ↩ -

Kirk T Van Gelder, Fundamentals of Automotive Technology Principles and Practice (Jones Bartlett Learning, 2018)

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.