This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

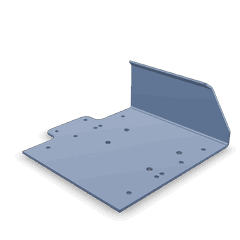

The 5407831 Electronic Control Module (ECM) Bracket by Cummins is a component designed to secure and protect the ECM within heavy-duty trucks. This part plays a role in the operation of these vehicles by ensuring the ECM remains safely housed and operational under various conditions. Cummins Inc., the manufacturer, is renowned for its expertise in diesel engine manufacturing and commitment to quality and innovation in the automotive industry 1.

Function and Role in Truck Operation

The 5407831 ECM Bracket serves to secure and protect the ECM, which is a vital component in the truck’s electronic system. By providing a stable and secure mounting point, the bracket helps to shield the ECM from physical damage, environmental factors, and electrical interference. This protection is integral to the ECM’s ability to manage engine functions, monitor performance, and communicate with other electronic systems within the truck. The reliability of the ECM bracket directly influences the overall functionality and reliability of the truck’s electronic systems 2.

Key Features

The 5407831 ECM Bracket is designed with specific characteristics that enhance its performance and longevity. Constructed from durable materials, it offers excellent corrosion resistance, ensuring it can withstand the harsh conditions often encountered in heavy-duty truck operations. Its design facilitates ease of installation, allowing for straightforward mounting and secure attachment to the truck’s chassis. These features contribute to the bracket’s effectiveness in protecting the ECM and supporting the truck’s electronic systems 3.

Benefits of Using the 5407831 ECM Bracket

Utilizing a high-quality ECM bracket like the 5407831 model offers several advantages. Enhanced protection for the ECM leads to improved system reliability, as the ECM is less susceptible to damage from vibrations, impacts, and environmental conditions. This reliability can result in potential cost savings over time, as reduced maintenance needs and fewer ECM-related issues can lead to lower operational costs. Additionally, the durability and corrosion resistance of the bracket contribute to its longevity, further enhancing its value 4.

Installation Process

Proper installation of the 5407831 ECM Bracket is crucial for ensuring the ECM is securely and correctly mounted. The process involves identifying the correct mounting location on the truck’s chassis, aligning the bracket with the designated points, and securing it in place using the provided fasteners. It is important to follow the manufacturer’s guidelines to ensure the bracket is installed correctly, which includes checking for proper alignment and secure attachment to prevent any movement or shifting that could affect the ECM’s performance.

Troubleshooting Common Issues

Common issues associated with ECM brackets and the ECM itself can include bracket misalignment, corrosion, and ECM malfunctions. To address these problems, it is important to conduct regular inspections of the bracket and ECM for signs of damage or wear. Misalignment can often be corrected by re-securing the bracket, while corrosion may require cleaning or, in severe cases, replacement of the bracket. ECM malfunctions should be diagnosed by a professional to determine the cause and appropriate solution.

Maintenance Tips

Regular maintenance checks and care for the ECM bracket are recommended to ensure its longevity and optimal performance. This includes inspecting the bracket for any signs of damage, corrosion, or wear, and cleaning it as necessary to remove dirt and debris that could affect its function. If significant damage is observed, or if the bracket shows signs of corrosion that cannot be cleaned away, it may be necessary to consider replacement to maintain the protection and reliability of the ECM.

Compatibility and Application

The 5407831 ECM Bracket is designed for specific types of trucks and ECMs, ensuring compatibility and optimal performance. It is important to use manufacturer-recommended parts to maintain the integrity of the truck’s electronic systems and ensure the ECM is properly protected and supported. This compatibility is crucial for the overall performance and reliability of the vehicle.

Cummins: A Brief Overview

Cummins Inc. is a leader in the diesel engine manufacturing industry, with a history of innovation and commitment to quality. Founded with a focus on engine technology, Cummins has expanded its expertise to include a wide range of products and services for the automotive industry. The company’s dedication to quality and innovation is evident in its products, including the 5407831 ECM Bracket, which is designed to meet the demanding requirements of heavy-duty truck operations.

Electronic Control Module Bracket (Part 5407831) Compatibility with Cummins Engines

The Electronic Control Module (ECM) Bracket, identified by part number 5407831, is a component designed to securely mount the ECM in various Cummins engine configurations. This bracket ensures the ECM is properly positioned and protected, facilitating optimal engine performance and reliability.

G855 CM558 and GTA855 CM558 (CM2358)

The ECM Bracket 5407831 is compatible with the G855 CM558 and GTA855 CM558 engines, including those with the CM2358 designation. These engines are part of the Cummins G-Series, known for their robust design and high performance in heavy-duty applications. The bracket’s design allows for precise alignment and mounting of the ECM, ensuring that the electronic control system functions seamlessly with the engine’s operational parameters.

G101

The G101 engine also benefits from the ECM Bracket 5407831. This bracket is engineered to fit the specific mounting requirements of the G101, providing a stable and secure platform for the ECM. The compatibility ensures that the electronic control system is properly integrated, enhancing the engine’s overall efficiency and reliability.

Grouping of Compatible Engines

The ECM Bracket 5407831 is designed to be versatile, fitting a range of Cummins engines while maintaining the necessary precision for electronic control system integration. By grouping the G855 CM558, GTA855 CM558 (CM2358), and G101 engines, it is evident that this bracket is a key component in ensuring the ECM is correctly mounted and protected across these engine models. This compatibility underscores the importance of using the correct mounting hardware to maintain the integrity and performance of the engine’s electronic systems.

Role of Part 5407831 Electronic Control Module (ECM) Bracket in Engine Systems

The part 5407831 Electronic Control Module (ECM) Bracket is a component in the mounting and stabilization of the Engine Control Module within various engine systems. This bracket ensures that the ECM is securely positioned, protecting it from vibrations and physical damage that could otherwise occur during engine operation.

When integrated into engine systems, the ECM Bracket facilitates the connection of the ECM to other vital components such as sensors, actuators, and the engine control unit (ECU). It allows for organized and neat wiring, reducing the risk of electrical interference and ensuring reliable signal transmission between the ECM and other engine components.

Additionally, the ECM Bracket contributes to the overall structural integrity of the engine system. By providing a stable mounting point for the ECM, it helps maintain the precise alignment of connected components, which is important for the accurate functioning of the engine’s electronic systems.

Conclusion

In summary, the 5407831 ECM Bracket plays a significant role in the reliable operation of engine systems by securing the ECM, organizing wiring, and contributing to the structural stability of the engine’s electronic components. Its compatibility with specific Cummins engines ensures that the ECM is correctly mounted and protected, enhancing the overall performance and reliability of the vehicle.

-

Design of Racing and High-Performance Engines 2004-2013, Douglas R. Fehan, SAE International, 2013

↩ -

The Repair of Vehicle Bodies Fifth Edition, Alan Robinson and Andrew Livesey, Elsevier, 2006

↩ -

Automotive Transmissions Fundamentals Selection Design and Application, Harald Naunheimer, Bernd Bertsche, Joachim Ryborz, Wolfgang Novak, Springer Vieweg, 2011

↩ -

SAE International’s Dictionary of Testing, Verification and Validation, Jon M. Quigley, SAE International, 2023

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.