This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

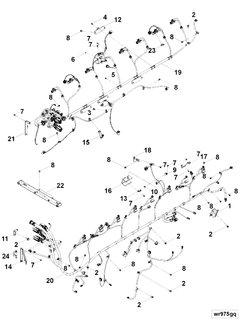

The Cummins 5409764 Electronic Control Module (ECM) Wiring Harness is a critical component in the operation of commercial trucks. This wiring harness is designed to facilitate communication and power transmission between the ECM and various other components within the truck’s electronic system. Its role is significant in ensuring the efficient and reliable performance of the vehicle.

Basic Concepts

Electronic Control Module Wiring Harnesses serve as the backbone of a vehicle’s electronic system. They are responsible for transmitting signals and power between the ECM and other electronic components. This facilitates the coordination and operation of various systems within the truck, such as the engine, transmission, and emissions control systems. The wiring harness ensures that all components can communicate effectively, allowing for optimal performance and efficiency 1.

Purpose and Role

The Cummins 5409764 ECM Wiring Harness plays a specific role within the truck’s electronic system. It is responsible for transmitting signals and power between the ECM and other components, such as sensors, actuators, and the engine. This allows the ECM to monitor and control various aspects of the truck’s operation, ensuring that all systems are working together seamlessly 2.

Key Features

The Cummins 5409764 ECM Wiring Harness is designed with several key features that enhance its performance and reliability. These include a robust construction using high-quality materials, which ensures durability and resistance to environmental factors. The harness is also designed to be compatible with various Cummins engine models and truck makes and models, providing versatility and ease of use 3.

Benefits

The Cummins 5409764 ECM Wiring Harness offers several benefits to commercial truck operators. These include improved efficiency, as the harness allows for better communication and coordination between the ECM and other components. This can lead to enhanced performance and fuel efficiency. Additionally, the harness is designed for reliability, ensuring that it can withstand the demands of commercial truck operation. Its compatibility with Cummins engines and other components also makes it a versatile choice for truck operators.

Installation and Compatibility

Proper installation of the Cummins 5409764 ECM Wiring Harness is crucial to ensure optimal performance and longevity. It is important to follow the manufacturer’s guidelines and recommendations for installation, which may include specific routing and securing procedures. The harness is compatible with various Cummins engine models and truck makes and models, making it a versatile choice for many commercial truck applications.

Troubleshooting and Maintenance

Common issues that may arise with the Cummins 5409764 ECM Wiring Harness include loose connections, damaged wires, or corrosion. Regular inspection and maintenance can help identify and address these issues before they lead to more significant problems. Troubleshooting tips may include checking for proper connections, inspecting wires for damage, and cleaning or replacing corroded components. Following the manufacturer’s maintenance recommendations can help ensure the optimal performance and longevity of the wiring harness.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history dating back to 1919, Cummins has established a strong reputation within the commercial truck industry for producing high-quality, reliable, and efficient products. The company offers a wide range of products and services, including engines, powertrains, and aftermarket parts, catering to various industries and applications.

Role of Part 5409764 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, specifically part 5409764, is an integral component in modern engine systems, facilitating seamless communication and power distribution between the ECM and various engine components. This harness is designed to connect the ECM to sensors, actuators, and other control units, ensuring that the engine operates efficiently and effectively.

Integration with Engine Components

-

Sensors: The ECM Wiring Harness interfaces with a variety of sensors such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and Manifold Absolute Pressure (MAP) sensor. These sensors provide real-time data to the ECM, allowing it to make precise adjustments to fuel injection, ignition timing, and other critical parameters.

-

Actuators: The harness also connects to actuators like the fuel injectors, throttle body, and variable valve timing (VVT) solenoids. These components rely on signals from the ECM to perform their functions, ensuring that the engine delivers optimal performance under varying conditions.

-

Ignition System: In ignition systems, the ECM Wiring Harness links the ECM to ignition coils and spark plugs. This connection enables the ECM to control the timing and duration of spark events, which is essential for combustion efficiency and emissions control.

-

Transmission Control: For engines with automatic transmissions, the harness connects the ECM to the Transmission Control Module (TCM). This link allows for coordinated shifts and ensures that the transmission operates in harmony with the engine’s performance demands.

-

Emissions Control: The harness plays a role in connecting the ECM to emissions control components such as the Exhaust Gas Recirculation (EGR) valve and the catalytic converter. These connections help the ECM monitor and regulate emissions, ensuring compliance with environmental standards.

-

Battery and Alternator: The ECM Wiring Harness also includes connections to the battery and alternator, providing the necessary power supply to the ECM and other electronic components. This ensures that the engine management system remains operational, even during periods of high electrical demand.

-

Diagnostic Connectors: Lastly, the harness incorporates diagnostic connectors that allow mechanics to interface with the On-Board Diagnostics (OBD) system. This feature is invaluable for troubleshooting and maintaining the engine system, as it provides access to error codes and live data streams.

Conclusion

In summary, the ECM Wiring Harness (part 5409764) is a vital component that ensures the ECM can effectively manage and control various engine functions, contributing to overall vehicle performance and reliability. Proper installation, regular maintenance, and understanding its role within the engine system are essential for maximizing the benefits of this Cummins part.

-

Quansheng Zhan, Shengbo Eben, Li Kun Deng. Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning, 2018.

↩ -

Michael Klyde and Kirk VanGelder. Advanced Automotive Electricity and Electronics. Jones Bartlett Learning, 2010.

↩ -

Zhiyu Han. Simulation and Optimization of Internal Combustion Engines. SAE International, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.