This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5410165 Time Delay Relay is a specialized component designed for use in commercial truck operations. Its purpose is to manage and control electrical circuits by introducing a time delay before activating or deactivating a circuit. This function is significant in ensuring the smooth and efficient operation of various electrical systems within commercial trucks 2.

Basic Concepts of Time Delay Relays

A time delay relay is an electrical device that introduces a predetermined delay between the application of an input signal and the activation or deactivation of an output circuit. This delay can be used to sequence operations, protect circuits from sudden surges, or allow systems to stabilize before engaging. In automotive systems, time delay relays are commonly used in applications such as headlight control, engine management systems, and auxiliary equipment operation 3.

Purpose of the Cummins 5410165 Time Delay Relay

The Cummins 5410165 Time Delay Relay plays a specific role in the operation of a commercial truck by managing the timing of electrical signals within the vehicle’s electrical system. It ensures that certain circuits are activated or deactivated at precise intervals, which can be crucial for the proper functioning of various truck systems. This relay helps in preventing electrical overloads, sequencing operations correctly, and enhancing the overall reliability of the truck’s electrical components 4.

Key Features

The Cummins 5410165 Time Delay Relay is characterized by several key features that enhance its performance and durability. Its design incorporates high-quality materials that ensure resistance to environmental factors such as moisture, dust, and temperature fluctuations. The relay is constructed with precision to provide accurate timing functions and reliable operation under varying conditions. Additionally, it may include unique attributes such as adjustable delay settings, which allow for customization based on specific application requirements 1.

Benefits of Using the Cummins 5410165 Time Delay Relay

Utilizing the Cummins 5410165 Time Delay Relay offers several advantages. It contributes to improved system reliability by ensuring that electrical circuits are managed with precision timing. This can lead to enhanced performance of the truck’s electrical systems and potentially reduce the risk of component failure. Moreover, the relay can contribute to cost savings by prolonging the lifespan of electrical components and reducing the need for frequent repairs or replacements 2.

Installation Process

Installing the Cummins 5410165 Time Delay Relay requires careful attention to detail to ensure proper functionality. The process involves identifying the correct location within the truck’s electrical system, disconnecting the battery to prevent electrical shocks, and connecting the relay according to the manufacturer’s instructions. Tools such as wire strippers, crimping tools, and a multimeter may be required to complete the installation successfully. It is important to follow all safety guidelines and ensure that all connections are secure and correctly aligned 3.

Troubleshooting Common Issues

Common problems associated with time delay relays can include incorrect timing, failure to activate or deactivate circuits, or electrical malfunctions. Troubleshooting steps may involve checking the relay’s connections, testing the input and output signals with a multimeter, and verifying that the delay settings are correctly configured. If the relay appears to be faulty, it may need to be replaced. Consulting the manufacturer’s documentation can provide specific guidance on diagnosing and resolving issues 4.

Maintenance Tips

Regular maintenance of the Cummins 5410165 Time Delay Relay is important to ensure its longevity and optimal performance. This includes inspecting the relay for signs of wear or damage, ensuring that all connections are secure, and cleaning the relay to remove any dirt or debris that may affect its operation. Periodically testing the relay’s function can help identify potential issues before they lead to system failures 1.

Safety Considerations

When working with the Cummins 5410165 Time Delay Relay, it is important to observe several safety guidelines. These include disconnecting the vehicle’s battery before beginning any work to prevent electrical shocks, wearing appropriate personal protective equipment, and ensuring that all tools and equipment are in good condition. Following these precautions can help prevent accidents and ensure safe operation during installation, maintenance, or troubleshooting procedures 2.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. With a history spanning over a century, Cummins has established a strong reputation in the automotive industry for producing high-quality, reliable products. The company’s extensive product range serves various markets, including commercial vehicles, construction equipment, and power generation, demonstrating its commitment to innovation and customer satisfaction 3.

Time Delay Relay 5410165 in Cummins Engines

The Time Delay Relay 5410165, manufactured by Cummins, is a critical component in the operation of several Cummins engine models. This relay is designed to manage the timing of electrical signals within the engine’s control system, ensuring that various functions are executed in a specific sequence to prevent damage and enhance performance.

QSK95 Engine

In the QSK95 engine, the Time Delay Relay 5410165 plays a pivotal role in managing the timing of the engine’s turbocharger system. This engine is known for its robust performance and reliability, often used in heavy-duty applications such as marine and stationary power generation. The relay ensures that the turbocharger’s boost pressure is applied gradually, preventing sudden surges that could harm the engine 4.

CM2350 Engine

The CM2350 engine also benefits from the Time Delay Relay 5410165. This engine is typically employed in medium-duty applications, such as construction equipment and agricultural machinery. The relay helps in the precise timing of the engine’s fuel injection and ignition systems, ensuring smooth operation and optimal fuel efficiency. It also aids in the management of the engine’s after-treatment systems, which are crucial for meeting stringent emissions standards 1.

K113 Engine

The K113 engine, another model in Cummins’ lineup, utilizes the Time Delay Relay 5410165 to manage the timing of its various electrical and mechanical systems. This engine is often found in on-highway applications, such as trucks and buses. The relay ensures that the engine’s various subsystems, including the cooling and lubrication systems, are activated in the correct sequence, enhancing the engine’s overall reliability and longevity 2.

Grouping of Engines

The QSK95 and CM2350 engines, while differing in their specific applications, share a common need for precise timing control in their turbocharger and fuel injection systems, respectively. The K113 engine, on the other hand, requires the relay for managing its on-highway systems, ensuring that it operates efficiently and reliably under varying conditions. The Time Delay Relay 5410165 is thus a versatile and essential component across these diverse engine models, highlighting its importance in Cummins’ engine technology 3.

Role of Part 5410165 Time Delay Relay in Engine Systems

The Time Delay Relay, identified as part 5410165, is an essential component in the orchestration of various engine systems. Its primary function is to introduce a timed delay in the activation or deactivation of electrical circuits, ensuring that operations occur in a controlled and sequential manner 4.

Integration with Accessories

In engine systems, accessories such as alternators, fuel pumps, and cooling fans rely on precise timing for optimal performance. The Time Delay Relay 5410165 ensures that these accessories do not engage simultaneously, which could lead to electrical overloads or inefficient operation. For instance, it can delay the activation of a fuel pump until the engine has reached a stable RPM, thereby preventing unnecessary wear and ensuring smooth operation 1.

Electrical System Management

The relay plays a significant role in managing the electrical load distribution across the engine system. By introducing delays, it prevents spikes in current draw that can occur when multiple high-draw accessories are activated at the same time. This is particularly important in systems where components like the starter motor and ignition system are in use, as it helps maintain voltage stability and protects sensitive electronic components from damage 2.

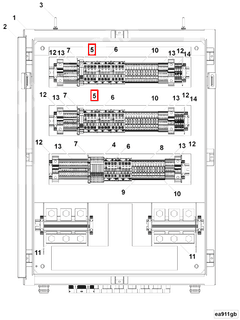

Junction Box Coordination

In conjunction with the junction box, the Time Delay Relay 5410165 enhances the overall efficiency of the electrical system. The junction box serves as a central distribution point for electrical signals and power. The relay ensures that signals sent to various components are timed correctly, allowing for a more organized and efficient flow of electricity. This is especially beneficial in complex engine systems where multiple signals need to be managed simultaneously, such as in modern engines with advanced fuel injection and emissions control systems 3.

Conclusion

By integrating the Time Delay Relay 5410165 into these systems, engineers and mechanics can achieve a more reliable and efficient engine operation, ultimately leading to improved performance and longevity of the engine components 4.

-

Cars Encyclopedia, Clive Gifford, DK Publishing, 2014

↩ ↩ ↩ ↩ -

Heavy Duty Truck Systems, Fifth Edition, Sean Bennett, Ian Andrew Norman, Delmar Cengage Learning, 2011

↩ ↩ ↩ ↩ ↩ -

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Springer, 2018

↩ ↩ ↩ ↩ ↩ -

Engine Testing: Theory and Practice: Third Edition, A.J. Martyr, SAE International, 2007

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.