This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

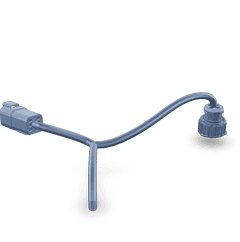

The 5416016 Electronic Control Module Wiring Harness by Cummins is a vital component in the electrical system of commercial trucks. It facilitates the connection between the Electronic Control Module (ECM) and various sensors and actuators throughout the vehicle. This part plays a role in ensuring the proper operation and communication within the truck’s electrical system, contributing to overall vehicle performance and reliability.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a network of wires and connectors designed to link the ECM to different components within the truck. It serves as the conduit for electrical signals, allowing the ECM to receive data from sensors and send commands to actuators. This interaction is fundamental to the truck’s operation, enabling the ECM to monitor and control various systems such as engine performance, transmission, and emissions 1.

Purpose of the 5416016 Electronic Control Module Wiring Harness

The 5416016 Electronic Control Module Wiring Harness is specifically designed to connect the ECM to a range of sensors and actuators in commercial trucks. Its role involves transmitting data from sensors to the ECM and relaying control signals from the ECM to actuators. This facilitates the ECM’s ability to manage engine functions, optimize performance, and ensure compliance with emissions standards 2.

Key Features

The 5416016 Electronic Control Module Wiring Harness is characterized by its robust design and the use of high-quality materials. It is engineered to withstand the harsh conditions typical of commercial truck environments, including exposure to vibrations, temperature fluctuations, and moisture. The harness features durable connectors and protective coatings that enhance its performance and longevity.

Benefits

The implementation of the 5416016 Electronic Control Module Wiring Harness in commercial trucks offers several advantages. It contributes to improved engine performance by ensuring efficient communication between the ECM and various components. Additionally, it enhances diagnostic capabilities, allowing for more accurate and timely identification of issues. The harness also increases the reliability of the truck’s electrical system, reducing the likelihood of malfunctions and improving overall vehicle dependability.

Installation Process

Installing the 5416016 Electronic Control Module Wiring Harness requires careful attention to detail and adherence to safety protocols. The process involves disconnecting the battery to prevent electrical shocks, routing the harness through the truck’s chassis to avoid interference with other components, and securely connecting it to the ECM and relevant sensors and actuators. Proper tools and equipment, such as wire strippers and crimping tools, are necessary for a successful installation. Safety precautions, including wearing protective gear and ensuring the work area is well-ventilated, should be observed throughout the process.

Troubleshooting and Maintenance

To maintain the optimal performance of the 5416016 Electronic Control Module Wiring Harness, regular inspections are recommended. This includes checking for signs of wear or damage to the wires and connectors, ensuring all connections are secure, and cleaning the harness to remove any dirt or debris that could interfere with its operation. Troubleshooting common issues may involve testing the electrical connections for continuity and using diagnostic tools to identify any faults within the system. Prompt attention to any detected issues can prevent more significant problems and ensure the longevity of the harness.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engines and components. The company’s product offerings include a wide range of diesel and natural gas engines, as well as aftermarket parts and services, all designed to meet the demanding requirements of commercial transportation.

Cummins Electronic Control Module Wiring Harness (Part 5416016) Compatibility

The Cummins Electronic Control Module (ECM) Wiring Harness, identified by part number 5416016, is designed to integrate seamlessly with a variety of Cummins engines. This wiring harness is a critical component that ensures the proper electrical connection between the ECM and various engine sensors and actuators, facilitating efficient engine operation and diagnostics.

QST30 Engine

The QST30 engine benefits from the 5416016 wiring harness, which provides the necessary electrical pathways for the ECM to communicate with the engine’s sensors and control systems. This harness ensures that the engine’s performance is optimized and that any potential issues are promptly identified and addressed.

CM2350 and T101 Engines

Similarly, the CM2350 and T101 engines are compatible with the 5416016 wiring harness. This compatibility ensures that the ECM can effectively manage the engine’s operations, including fuel injection, ignition timing, and emissions control. The harness’s design allows for a reliable and robust connection, which is essential for maintaining the engine’s performance and longevity.

By using the 5416016 wiring harness, these engines can benefit from enhanced diagnostic capabilities and improved overall efficiency. The harness’s compatibility with these engines underscores Cummins’ commitment to providing high-quality, reliable components that meet the demands of modern engine technology.

Role of Part 5416016 Electronic Control Module Wiring Harness in Engine Systems

The part 5416016 Electronic Control Module (ECM) Wiring Harness is an integral component in modern engine systems, facilitating seamless communication and power distribution among various engine components.

Integration with the Fuel System

In fuel-injected engines, the ECM Wiring Harness connects the ECM to the fuel injectors, fuel pump, and fuel pressure sensor. This connection allows the ECM to precisely control fuel delivery based on engine load, RPM, and other parameters. The harness ensures that the fuel system operates efficiently, optimizing fuel economy and reducing emissions.

Connection to the Air Intake System

The harness also interfaces with the Mass Air Flow (MAF) sensor and the Manifold Absolute Pressure (MAP) sensor. These sensors provide the ECM with data on the amount of air entering the engine, enabling it to adjust the air-fuel mixture for optimal combustion. This results in improved engine performance and reduced pollutants.

Role in Emission Control

For emission control systems, the ECM Wiring Harness links the ECM to components like the Oxygen (O2) sensors, Exhaust Gas Recirculation (EGR) valve, and Catalytic Converter. By monitoring and controlling these components, the ECM ensures that the engine meets emission standards, contributing to a cleaner environment.

Interaction with the Ignition System

In engines equipped with electronic ignition systems, the harness connects the ECM to the ignition coils and spark plugs. This allows the ECM to control the timing and duration of the spark, enhancing combustion efficiency and engine performance.

Communication with Ancillary Systems

Beyond the primary engine components, the ECM Wiring Harness also facilitates communication with ancillary systems such as the engine cooling system, variable valve timing system, and turbocharger (if equipped). This comprehensive connectivity enables the ECM to manage overall engine operation more effectively.

Conclusion

The 5416016 Electronic Control Module Wiring Harness by Cummins is a critical component in the electrical system of commercial trucks. It ensures efficient communication between the ECM and various sensors and actuators, contributing to improved engine performance, enhanced diagnostic capabilities, and increased reliability of the truck’s electrical system. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.