5475400

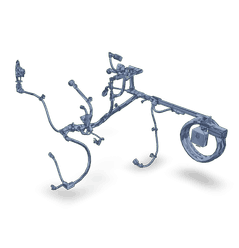

Electronic Control Module Wiring Harness

Cummins®

AVAILABLE

6 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 5475400 Electronic Control Module Wiring Harness is a vital component in the electrical system of commercial trucks. It facilitates communication between the Electronic Control Module (ECM) and various sensors and actuators throughout the vehicle. This harness ensures that the ECM receives accurate data and can effectively control the truck’s systems, contributing to overall performance and efficiency.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a network of wires and connectors designed to link the ECM with other electronic components in a truck. It consists of multiple wires, each serving a specific function, bundled together for protection and organization. The harness allows for the transmission of data and power between the ECM and components such as sensors, actuators, and other control units. This system ensures that the ECM can monitor and adjust the truck’s operations in real-time 1.

Purpose and Role in Truck Operation

The 5475400 Electronic Control Module Wiring Harness plays a significant role in the operation of a truck by enabling the ECM to communicate with various electronic systems. It allows the ECM to receive input from sensors regarding engine performance, fuel efficiency, and other critical parameters. Additionally, it enables the ECM to send commands to actuators to adjust engine functions, transmission shifts, and other operations. This continuous data exchange ensures that the truck operates efficiently and reliably 2.

Key Features

The Cummins 5475400 Electronic Control Module Wiring Harness is designed with several key features that enhance its performance and durability. It is constructed using high-quality materials resistant to wear, corrosion, and environmental factors. The harness is engineered to withstand the vibrations and harsh conditions typical in commercial truck operations. Its design includes robust connectors and terminals that ensure secure and reliable connections. Additionally, the harness is tailored to fit specific truck models, ensuring a precise and efficient integration into the vehicle’s electrical system 3.

Benefits

The 5475400 Electronic Control Module Wiring Harness offers several benefits that contribute to the overall performance and reliability of a truck. By facilitating accurate and timely communication between the ECM and other electronic components, it helps improve engine performance and fuel efficiency. The harness also enhances the reliability of the truck’s electronic systems by ensuring consistent and secure data transmission. Furthermore, its durable construction reduces the likelihood of failures and the need for frequent repairs, leading to lower maintenance costs and increased uptime.

Installation and Integration

Proper installation and integration of the 5475400 Electronic Control Module Wiring Harness are crucial for ensuring its effective operation. The installation process involves connecting the harness to the ECM and various sensors and actuators throughout the truck. It is important to follow the manufacturer’s guidelines to ensure that all connections are secure and correctly aligned. Additionally, any specific requirements or considerations for the truck model should be taken into account to ensure optimal performance and compatibility.

Troubleshooting and Maintenance

Regular maintenance and timely troubleshooting are important for ensuring the longevity and optimal performance of the 5475400 Electronic Control Module Wiring Harness. Common issues may include loose connections, damaged wires, or corroded terminals. Inspecting the harness regularly for signs of wear or damage can help identify potential problems early. Maintenance tips include keeping the harness clean and dry, ensuring all connections are tight, and protecting it from physical damage. If issues arise, consulting the manufacturer’s guidelines or a professional technician can help diagnose and resolve problems effectively.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the diesel engine industry. The company’s products are used in a wide range of applications, including commercial trucks, construction equipment, agricultural machinery, and power generation. Cummins is committed to advancing technology and providing solutions that meet the evolving needs of its customers.

Role of Part 5475400 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified by part number 5475400, serves as the vital connective tissue within modern engine systems. This harness is responsible for facilitating the communication and power distribution between the ECM and various engine components.

Integration with Engine Components

-

Sensors: The harness connects a multitude of sensors—such as the Mass Air Flow (MAF) sensor, Manifold Absolute Pressure (MAP) sensor, and Oxygen (O2) sensors—to the ECM. These sensors provide real-time data on air intake, fuel mixture, and exhaust emissions, allowing the ECM to make precise adjustments for optimal performance and efficiency.

-

Actuators: It interfaces with actuators including the fuel injectors, throttle body, and variable valve timing (VVT) solenoids. By transmitting signals from the ECM, the harness ensures these components operate in harmony with the engine’s requirements, enhancing both power output and fuel economy.

-

Ignition System: The harness links the ignition coils and spark plugs to the ECM. This connection allows for the precise timing of spark delivery, which is essential for combustion efficiency and reducing emissions.

-

Emission Control Systems: It also routes signals to emission control components like the Exhaust Gas Recirculation (EGR) valve and the catalytic converter. Proper function of these parts is imperative for meeting environmental regulations and maintaining engine health.

-

Power Supply: Beyond signal transmission, the harness ensures a stable power supply to the ECM and other electronic components, safeguarding against voltage fluctuations that could disrupt engine operation.

In summary, the ECM Wiring Harness (part 5475400) is integral to the seamless operation of engine systems. It ensures that all electronic components work in concert, allowing the ECM to execute its role as the brain of the engine effectively.

Conclusion

The Cummins 5475400 Electronic Control Module Wiring Harness is a critical component for the efficient and reliable operation of commercial trucks. Its role in facilitating communication between the ECM and various electronic components ensures optimal engine performance, fuel efficiency, and reliability. Proper installation, regular maintenance, and timely troubleshooting are essential for maximizing the benefits of this Cummins part.

-

Heywood, John. Internal Combustion Engine Fundamentals. McGraw-Hill Education, 2019.

↩ -

Brown Jr, Andrew. Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences, 2010.

↩ -

Fijalkowski, BT. Automotive Mechatronics Operational and Practical Issues Volume 1. Springer, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.