This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

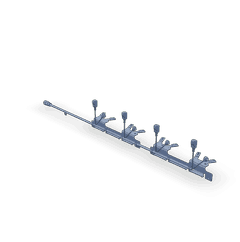

The 5538112 Electronic Control Module Wiring Harness, manufactured by Cummins, is a vital component in the operation of commercial trucks. Cummins, a well-established name in the automotive industry, is known for its commitment to quality and innovation. This wiring harness is designed to facilitate the electrical connections necessary for the proper functioning of the truck’s electronic control module (ECM), which is integral to the vehicle’s overall performance and efficiency.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a collection of wires and connectors that link the ECM to various sensors, actuators, and other electronic components within the truck. The harness typically includes insulated wires, connectors, terminals, and protective housings. Its function is to transmit electrical signals and power between the ECM and the components it controls, ensuring that the truck operates smoothly and efficiently 1.

Role of the 5538112 Electronic Control Module Wiring Harness in Truck Operation

The 5538112 Wiring Harness plays a significant role in the operation of a commercial truck by providing the necessary electrical connections for the ECM. This harness enables the ECM to communicate with various systems such as the engine, transmission, brakes, and emissions control systems. By facilitating these connections, the harness ensures that the ECM can monitor and control these systems effectively, contributing to the truck’s overall performance, fuel efficiency, and compliance with emissions regulations 2.

Key Features of the 5538112 Wiring Harness

The 5538112 Wiring Harness is characterized by several key features that enhance its performance and reliability. Its design incorporates high-quality materials that are resistant to wear, corrosion, and environmental factors. The harness is engineered to withstand the harsh conditions typically encountered in commercial trucking, such as vibrations, temperature fluctuations, and exposure to chemicals. Additionally, the harness features precise connector alignments and secure terminal connections, which help to ensure reliable signal transmission and power delivery.

Benefits of Using the 5538112 Wiring Harness

Utilizing the 5538112 Wiring Harness offers several benefits. It contributes to improved efficiency by ensuring that the ECM can effectively manage the truck’s systems. The harness’s robust construction and high-quality materials enhance its reliability, reducing the likelihood of electrical failures. Furthermore, its design facilitates ease of maintenance, allowing for straightforward diagnosis and repair of any issues that may arise.

Installation Considerations

When installing the 5538112 Wiring Harness, it is important to follow guidelines and best practices to ensure proper functionality. This may include verifying that all connections are secure and that the harness is routed away from potential sources of damage, such as sharp edges or high-temperature areas. Special tools may be required for certain installations, and it is advisable to consult the manufacturer’s instructions for specific recommendations.

Troubleshooting Common Issues

Identifying and resolving common issues with the 5538112 Wiring Harness can be achieved through systematic diagnostic steps. These may include checking for loose connections, inspecting the harness for signs of wear or damage, and using diagnostic tools to test electrical continuity. Potential solutions could involve repairing or replacing damaged sections of the harness or re-securing loose connections.

Maintenance Tips

Regular maintenance of the 5538112 Wiring Harness is crucial for ensuring its longevity and optimal performance. This includes routine inspections for signs of wear, corrosion, or damage. Cleaning the harness and its connections to remove dirt and debris can also help to maintain reliable electrical connections. Additionally, protecting the harness from physical damage and environmental factors will contribute to its durability.

Cummins: A Brief Overview

Cummins is a renowned manufacturer with a strong reputation in the automotive industry. The company has a history of innovation and commitment to quality, which is reflected in its wide range of automotive components. Cummins’ dedication to advancing technology and meeting the needs of its customers has established it as a trusted name in the industry.

Cummins Electronic Control Module Wiring Harness (Part 5538112)

The Cummins Electronic Control Module Wiring Harness, identified by part number 5538112, is a critical component in the electrical architecture of several Cummins engine models. This wiring harness is designed to facilitate the transmission of electrical signals between the Electronic Control Module (ECM) and various sensors and actuators throughout the engine system.

Application in Cummins Engines

QSK60 Series

The QSK60 series engines, known for their robust performance and reliability, integrate the 5538112 wiring harness to ensure seamless communication between the ECM and the engine’s electronic components. This harness is essential for maintaining optimal engine performance and diagnostics.

CM850 Series

In the CM850 series, the 5538112 wiring harness plays a pivotal role in the engine’s electronic management system. It ensures that the ECM can effectively monitor and control various engine parameters, contributing to the engine’s efficiency and longevity.

MCRS Series

The MCRS series engines, which are often used in marine applications, also rely on the 5538112 wiring harness. This component is crucial for the proper functioning of the engine’s electronic systems, ensuring that all sensors and actuators communicate effectively with the ECM.

Importance of the Wiring Harness

The 5538112 wiring harness is integral to the overall functionality of these engines. It ensures that the ECM can accurately receive data from various sensors and send commands to the necessary actuators. This seamless communication is vital for maintaining engine performance, efficiency, and reliability 3.

Installation and Maintenance

Proper installation and maintenance of the 5538112 wiring harness are essential to prevent electrical faults and ensure the engine operates at peak performance. Technicians should follow Cummins’ recommended procedures for installation and regularly inspect the harness for signs of wear or damage.

Conclusion

The 5538112 Electronic Control Module Wiring Harness is a critical component in the operation of commercial trucks and Cummins engines. Its role in facilitating communication between the ECM and various electronic components ensures optimal performance, efficiency, and reliability. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.