This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

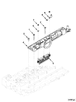

The Electrical Connector part 4896655, manufactured by Cummins, is a vital component in the electrical systems of several Cummins diesel engines. This part is designed to ensure reliable and efficient electrical connections within the engine’s system, facilitating the transmission of power and signals between various engine components.

Basic Concepts of Electrical Connectors

Electrical connectors are devices used to join electrical circuits together, facilitating the transfer of electrical power and data. In vehicles, these connectors play a crucial role in linking different components of the electrical system, ensuring that power is distributed efficiently and that data is transmitted accurately between various systems and sensors 1.

Purpose of the 4896655 Electrical Connector

The 4896655 Electrical Connector is specifically designed to serve as a reliable link in the electrical systems of Cummins engines. It is applied in various engine systems, including but not limited to, the engine control unit (ECU), transmission systems, and other electronic modules. By providing a secure connection, it ensures that electrical signals and power are transmitted effectively, contributing to the overall functionality and performance of the engine 2.

Key Features

The 4896655 Electrical Connector is characterized by several key features that enhance its performance and durability. Its design incorporates robust materials that are resistant to wear and environmental factors. Additionally, it features a locking mechanism that ensures a secure connection, minimizing the risk of disconnection or poor contact. These attributes contribute to its reliability and longevity in demanding engine operations 3.

Benefits

The use of the 4896655 Electrical Connector offers several advantages in engine operations. It provides improved reliability by ensuring consistent electrical connections, which is crucial for the proper functioning of engine systems. Additionally, it enhances efficiency by facilitating smooth data and power transmission. Safety is also improved, as secure connections reduce the risk of electrical faults that could lead to hazardous situations 4.

Installation and Integration

Proper installation and integration of the 4896655 Electrical Connector within an engine’s electrical system are crucial for its effective operation. Best practices include ensuring that the connector is correctly aligned and securely fastened to prevent any loose connections. It is also important to follow manufacturer guidelines to avoid potential challenges such as incorrect wiring or damage to the connector during installation.

Troubleshooting and Maintenance

Identifying common issues with the 4896655 Electrical Connector involves regular inspection for signs of wear, corrosion, or loose connections. Diagnostic procedures may include testing the electrical continuity and ensuring that all connections are secure. Maintenance tips to ensure longevity and optimal performance include cleaning the connector regularly and replacing it if significant wear or damage is detected.

Safety Considerations

When working with the 4896655 Electrical Connector, it is important to observe safety practices and precautions to prevent accidents. This includes ensuring that the engine’s electrical system is de-energized before any work is performed on the connector. Additionally, using appropriate personal protective equipment (PPE) and following industry standards for electrical work are crucial to ensure safety and compliance.

Environmental Impact

The use and disposal of the 4896655 Electrical Connector have environmental considerations. Efforts should be made to recycle the connector at the end of its life to minimize waste. Additionally, sustainable practices in manufacturing and using the connector can contribute to reducing its environmental footprint.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, emissions solutions, and related technologies. With a history of innovation and a commitment to quality, Cummins serves commercial, industrial, construction, and transportation markets worldwide, providing reliable and efficient power solutions.

Application in Cummins Engines

ISBE CM800 and QSB4.5 CM850 (CM2850)

The Electrical Connector part 4896655 is integral to the ISBE CM800 and QSB4.5 CM850 (CM2850) engines. These engines are known for their robust performance and reliability in various applications, from industrial to marine uses. The connector ensures that the electrical circuits within these engines function smoothly, maintaining the integrity of the engine’s control systems and auxiliary functions.

QSB5.9 CM550

Similarly, in the QSB5.9 CM550 engine, the Electrical Connector part 4896655 plays a vital role. This engine is designed for heavy-duty applications, requiring a dependable electrical connection to support its high-performance capabilities. The connector’s design allows for easy installation and maintenance, ensuring that the engine’s electrical systems remain operational under demanding conditions.

Importance of the Electrical Connector

The Electrical Connector part 4896655 is essential for maintaining the electrical integrity of the engines. It ensures that all electrical connections are secure and free from corrosion, which can lead to electrical failures. This part is designed to withstand the harsh environments in which these engines operate, providing a reliable connection that can endure high temperatures and vibrations.

Compatibility and Installation

This connector is engineered to fit seamlessly with the electrical systems of the ISBE CM800, QSB4.5 CM850 (CM2850), and QSB5.9 CM550 engines. Its compatibility with these engines ensures that it can be easily integrated into the existing electrical architecture, facilitating straightforward installation and reducing downtime during maintenance or repairs.

Role of Part 4896655 Electrical Connector in Engine Systems

The 4896655 Electrical Connector is integral to the efficient operation of several engine components, ensuring seamless communication and power distribution.

In the Air Intake Manifold, this connector facilitates the electrical signals necessary for sensors that monitor air flow and temperature. These sensors provide data to the Engine Control Unit (ECU), allowing for precise fuel injection and ignition timing adjustments.

When integrated with the Manifold, the connector supports the operation of heating elements or sensors that help in maintaining optimal manifold temperature, which is vital for efficient combustion and reducing emissions.

For the Air Intake system, the 4896655 Electrical Connector ensures that components such as mass airflow sensors and throttle position sensors receive consistent power and can transmit accurate data to the ECU. This data is essential for the ECU to make real-time adjustments to the air-fuel mixture, enhancing engine performance and fuel efficiency.

Overall, the 4896655 Electrical Connector plays a significant role in maintaining the integrity and performance of these engine systems by ensuring reliable electrical connections and data transmission.

Conclusion

By using the Electrical Connector part 4896655, technicians and operators can be confident that their Cummins engines will maintain optimal electrical performance, contributing to the overall reliability and efficiency of the engine systems.

-

Moustafa ElGindy and Zeinab ElSayegh, Road and Off-Road Vehicle Dynamics, Springer Nature, 2023.

↩ -

Konrad Reif, Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems, Springer Vieweg, 2014.

↩ -

Kazimierz Lejda and Pawel Wos, Internal Combustion Engines, InTech, 2012.

↩ -

P. A. Lakshminarayanan and Avinash Kumar, Design and Development of Heavy Duty Diesel Engines: A Handbook, Springer Nature, 2020.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.