This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

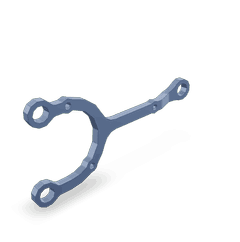

The Electronic Control Module Bracket, Part #3977324, manufactured by Cummins, is a component designed to support the Electronic Control Module (ECM) in commercial trucks. This part plays a role in ensuring the ECM is securely mounted and protected, contributing to the overall reliability and performance of the vehicle’s electronic systems.

Function and Operation

The Electronic Control Module Bracket serves as a mounting solution for the ECM, which is a central component in the truck’s electronic system. By securely holding the ECM in place, the bracket helps maintain the integrity of the electronic connections and protects the module from physical damage and environmental factors. This support is vital for the ECM to function correctly, as it manages various engine and vehicle operations, including fuel injection, emissions control, and diagnostic reporting 1.

Key Features

This Cummins part is constructed from durable materials designed to withstand the rigors of commercial truck environments. It features a robust design that includes corrosion-resistant coatings and high-strength fasteners. The bracket offers versatile mounting options, allowing for secure attachment in various truck configurations. Additionally, its design includes provisions for efficient heat dissipation, which helps maintain optimal operating temperatures for the ECM.

Benefits

Utilizing the 3977324 provides several advantages. It offers enhanced protection for the ECM, reducing the risk of damage from vibrations, impacts, and harsh environmental conditions. The bracket’s durable construction ensures long-term reliability, minimizing the need for frequent replacements. Furthermore, its design facilitates ease of installation, allowing for quick and secure mounting of the ECM.

Installation Process

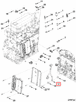

Installing the Electronic Control Module Bracket involves several steps to ensure a secure and proper fit. Begin by identifying the correct mounting location on the truck’s frame or chassis. Use the provided fasteners to attach the bracket, ensuring all connections are tight and secure. Carefully place the ECM into the bracket, making sure it is properly aligned and seated. Finally, connect the electrical harness to the ECM, following the manufacturer’s wiring diagram to ensure all connections are correct.

Maintenance and Troubleshooting

To maintain the Electronic Control Module Bracket and ensure its longevity, regular inspections are recommended. Check for any signs of corrosion, damage, or loose fasteners, and address these issues promptly. In case of common problems such as ECM malfunctions, verify the bracket’s integrity and connections. Ensure that the ECM is securely mounted and that all electrical connections are intact and free from corrosion 2.

Integration with Other Systems

The Electronic Control Module Bracket plays a role in integrating the ECM with other truck systems. It supports the ECM’s function in communicating with the engine control unit and diagnostic systems, ensuring a cohesive electronic management solution. This integration allows for efficient monitoring and control of engine performance, emissions, and other critical functions, contributing to the overall efficiency and reliability of the truck.

Safety Considerations

When installing or maintaining the Electronic Control Module Bracket, it is important to observe safety guidelines to prevent accidents and ensure compliance with industry standards. Ensure the truck is parked on a level surface and the engine is off before beginning any work. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect against injuries. Follow all manufacturer instructions and recommendations to ensure a safe and effective installation 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a strong reputation in the commercial truck industry, Cummins is known for its innovative products, commitment to quality, and customer-focused approach. The company’s extensive product range and expertise make it a trusted partner for commercial vehicle operators worldwide.

Compatibility with Cummins Engines

The Electronic Control Module (ECM) Bracket, identified as part 3977324 by Cummins, is designed to secure the ECM in various Cummins engine models. This bracket ensures the ECM is properly positioned and protected within the engine compartment. Below is a detailed description of how this part fits with the specified Cummins engines.

ISB Series

- ISB CM2150

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISBE CM2150

- ISBE4 CM850

The ISB series engines, including the ISB CM2150, ISB/ISD4.5 CM2150 B119, ISB/ISD6.7 CM2150 SN, ISBE CM2150, and ISBE4 CM850, all utilize the ECM Bracket 3977324. This bracket is engineered to fit the specific layout and mounting points of these engines, ensuring the ECM is securely fastened and properly aligned. The bracket’s design accommodates the unique dimensions and placement requirements of the ISB series, providing a stable and reliable mounting solution.

ISB6.7 Series

- ISB6.7 CM2250

The ISB6.7 CM2250 engine also integrates the ECM Bracket 3977324. This part is tailored to fit the specific architecture of the ISB6.7 series, ensuring that the ECM is positioned correctly within the engine bay. The bracket’s design allows for easy installation and secure fastening, maintaining the integrity of the ECM’s position and protecting it from environmental factors.

ISD Series

- ISD4.5 CM2220 D108

The ECM Bracket 3977324 is compatible with the ISD4.5 CM2220 D108 engine. This bracket is specifically designed to fit the mounting points and spatial constraints of the ISD4.5 series, ensuring the ECM is held firmly in place. The bracket’s robust construction provides the necessary support and stability for the ECM, contributing to the engine’s overall performance and reliability.

QSB Series

- QSB4.5 CM850 (CM2850)

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

The QSB series engines, including the QSB4.5 CM850 (CM2850), QSB6.7 CM850 (CM2850), and QSB7 CM2880 B117, also utilize the ECM Bracket 3977324. This part is designed to fit the specific mounting requirements of the QSB series, ensuring the ECM is securely fastened and properly aligned. The bracket’s design accommodates the unique layout of these engines, providing a stable and reliable mounting solution that enhances the engine’s operational efficiency.

Role of Part 3977324 Electronic Control Module Bracket in Engine Systems

The 3977324 Electronic Control Module (ECM) Bracket is integral to the structural and functional integrity of modern engine systems. This bracket securely mounts the ECM, ensuring it remains in the optimal location for effective communication with other engine components.

The ECM, often referred to as the brain of the engine, relies on precise positioning to interact with the Engine Control Module (ECM) and other critical systems. The bracket facilitates this by providing a stable platform that withstands the vibrations and harsh conditions within the engine compartment.

Moreover, the ECM Bracket ensures that the Electronic Control Module Support is adequately secured. This support is essential for maintaining the ECM’s alignment and protecting it from physical damage.

In summary, the 3977324 ECM Bracket plays a role in the reliable operation of engine systems by ensuring the ECM is correctly positioned and supported, thereby enabling efficient communication and control over various engine functions.

Conclusion

The 3977324 Electronic Control Module Bracket is a critical component in the operation and maintenance of Cummins engines. Its robust design, compatibility with various engine models, and role in ensuring the ECM’s secure and optimal positioning contribute to the overall efficiency and reliability of the engine systems. Regular maintenance and proper installation are essential to maximize the benefits of this part.

-

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill, 2018.

↩ -

Klyde, Michael and VanGelder, Kirk. Advanced Automotive Electricity and Electronics. Jones Bartlett Learning, 2010.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.