2864500

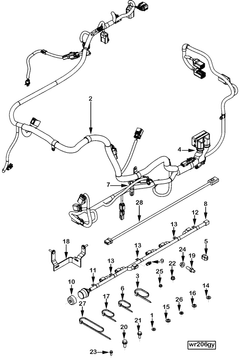

Electronic Control Module Wiring Harness

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Electronic Control Module Wiring Harness (Part #2864500) by Cummins is a vital component in the electronic systems of heavy-duty trucks. This wiring harness is designed to facilitate the communication between the Electronic Control Module (ECM) and various sensors and actuators throughout the vehicle. Its role is significant in ensuring the efficient and reliable operation of the truck’s electronic systems 1.

Basic Concepts

Electronic Control Module Wiring Harnesses are integral to the vehicle’s electronics and communication systems. They serve as the conduit through which the ECM communicates with sensors and actuators, allowing for the monitoring and control of various vehicle functions. Understanding the basic concepts of these wiring harnesses is fundamental to grasping their importance in modern vehicle electronics 2.

Purpose and Function

The 2864500 Electronic Control Module Wiring Harness is designed to enable seamless communication between the ECM and the truck’s sensors and actuators. This communication is crucial for the operation of the truck, as it allows the ECM to receive data from sensors and send commands to actuators, thereby controlling various aspects of the vehicle’s performance. The harness plays a role in ensuring that this communication is accurate and timely, contributing to the overall efficiency and reliability of the truck 3.

Key Features

The 2864500 Electronic Control Module Wiring Harness is characterized by its robust design and the use of high-quality materials. These features enhance its performance and reliability, ensuring that it can withstand the demanding conditions of heavy-duty truck operations. The harness is also designed with specific connectors and terminals that are compatible with Cummins engines and other truck components, facilitating easy installation and integration.

Benefits

The use of the 2864500 Electronic Control Module Wiring Harness offers several benefits. It contributes to improved engine performance by ensuring that the ECM receives accurate data from sensors and can effectively control actuators. This leads to enhanced fuel efficiency and increased reliability of the truck’s electronic systems. The harness also plays a role in reducing the risk of electrical faults, which can lead to downtime and increased maintenance costs.

Installation and Compatibility

The installation process of the 2864500 Electronic Control Module Wiring Harness is designed to be straightforward, with clear instructions provided to ensure proper integration with Cummins engines and other truck components. Its compatibility with a wide range of Cummins engines makes it a versatile choice for heavy-duty truck applications.

Troubleshooting and Maintenance

To ensure the optimal performance of the 2864500 Electronic Control Module Wiring Harness over time, regular maintenance and troubleshooting practices are recommended. This includes checking for signs of wear or damage, ensuring all connections are secure, and addressing any issues promptly to prevent further complications.

Safety Considerations

When installing, maintaining, or operating the 2864500 Electronic Control Module Wiring Harness, it is important to follow proper safety procedures. This includes handling the harness with care to avoid damage, ensuring all electrical connections are secure to prevent short circuits, and taking precautions to avoid electrical hazards.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the automotive industry. The company’s product offerings are designed to meet the demanding requirements of heavy-duty applications, ensuring reliable performance and efficiency.

ISM CM876 Engine Compatibility

The Electronic Control Module Wiring Harness part number 2864500, manufactured by Cummins, is specifically designed to integrate seamlessly with the ISM CM876 engine. This wiring harness plays a crucial role in ensuring that the engine’s electronic control module (ECM) is properly connected to various sensors and actuators throughout the engine system.

The ISM CM876 engine is known for its robust performance and reliability, often utilized in heavy-duty applications. The wiring harness is engineered to withstand the demanding conditions these engines typically operate under, ensuring a stable and efficient electrical connection.

ISM CM876 and ISM CM870 Engine Group

The ISM CM876 engine shares many components with the ISM CM870 engine, making the wiring harness part number 2864500 compatible with both models. This compatibility allows for easier maintenance and repair, as technicians can use the same wiring harness across different engine variants within this group.

ISM CM876 and ISM CM850 Engine Group

Similarly, the ISM CM876 engine is part of a broader family of engines that includes the ISM CM850. The wiring harness part number 2864500 is also designed to fit within this engine group, providing a standardized solution for electrical connectivity. This standardization helps in reducing inventory costs and simplifies the repair process for service providers.

ISM CM876 and ISM CM830 Engine Group

The ISM CM876 engine is also compatible with the ISM CM830 engine, and the wiring harness part number 2864500 is engineered to work with this engine as well. This compatibility extends the usability of the wiring harness across multiple engine models, ensuring that the same part can be used in various applications without the need for multiple specialized components.

ISM CM876 and ISM CM820 Engine Group

Lastly, the ISM CM876 engine shares design elements with the ISM CM820 engine, making the wiring harness part number 2864500 suitable for this engine as well. This compatibility further enhances the versatility of the wiring harness, allowing it to be used across a wide range of engine models within the ISM series.

Role of Part 2864500 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified by part number 2864500, is an integral component in modern engine systems, facilitating seamless communication and power distribution between the ECM and various engine components. This wiring harness is meticulously designed to ensure reliable and efficient operation of the engine by connecting the ECM to sensors, actuators, and other control units.

Integration with Engine Components

-

Sensors: The ECM Wiring Harness connects the ECM to a variety of sensors such as the Mass Air Flow (MAF) sensor, Manifold Absolute Pressure (MAP) sensor, Oxygen (O2) sensors, and Crankshaft Position (CKP) sensor. These sensors provide real-time data to the ECM, allowing it to make precise adjustments to fuel injection, ignition timing, and other critical parameters.

-

Actuators: This harness also links the ECM to actuators including the fuel injectors, throttle body, idle air control valve, and various solenoids. By transmitting signals from the ECM, these actuators can adjust engine performance based on the data received from the sensors.

-

Ignition System: The wiring harness ensures that the ECM can control the ignition system components such as the ignition coils and spark plugs. This allows for optimized ignition timing, which is essential for efficient combustion and overall engine performance.

-

Transmission Control: In engines equipped with automatic transmissions, the ECM Wiring Harness connects the ECM to the Transmission Control Module (TCM). This integration allows for coordinated control of engine and transmission functions, enhancing drivability and fuel efficiency.

-

Emission Control Systems: The harness facilitates communication between the ECM and emission control components like the Exhaust Gas Recirculation (EGR) valve and the catalytic converter. This ensures that the engine meets environmental regulations while maintaining performance.

-

Ancillary Systems: Additionally, the ECM Wiring Harness may connect to ancillary systems such as the air conditioning compressor, electric cooling fans, and variable valve timing systems. These connections allow the ECM to manage these systems based on operating conditions, further optimizing engine performance and efficiency.

In summary, the ECM Wiring Harness (part 2864500) plays a significant role in the coordination and control of various engine components, ensuring that the engine operates smoothly, efficiently, and in compliance with emission standards.

Conclusion

The 2864500 Electronic Control Module Wiring Harness is a critical component in the electronic systems of heavy-duty trucks, ensuring efficient and reliable operation. Its robust design, compatibility with various Cummins engines, and role in facilitating communication between the ECM and engine components make it an essential part of modern engine systems. Regular maintenance and adherence to safety procedures are vital to maximize the performance and longevity of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.