2864516

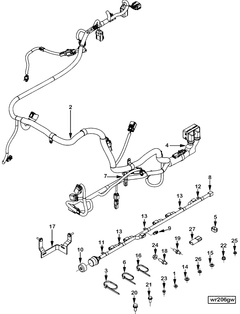

Electronic Control Module Wiring Harness

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Electronic Control Module Wiring Harness (Part #2864516) by Cummins is a vital component in the electrical system of commercial trucks. This wiring harness facilitates the connection between the Electronic Control Module (ECM) and various sensors and actuators throughout the vehicle. Its role is significant in ensuring the proper operation and communication within the truck’s electrical system, contributing to overall vehicle performance and reliability 1.

Basic Concepts

Electronic Control Module Wiring Harnesses are integral to a vehicle’s electrical system. They serve as the conduit through which the ECM communicates with sensors and actuators. This communication is crucial for the monitoring and control of various engine and vehicle functions. The wiring harness consists of a network of wires, connectors, and terminals designed to withstand the harsh environments typically encountered in commercial trucking 2.

Purpose and Role

The 2864516 Electronic Control Module Wiring Harness is designed to connect the ECM to a variety of sensors and actuators within the truck. This connection allows the ECM to receive data from sensors regarding engine and vehicle conditions and to send commands to actuators for adjustments and controls. The harness plays a role in facilitating real-time data exchange, which is fundamental for the ECM to make informed decisions and adjustments to optimize engine performance and efficiency 3.

Key Features

The 2864516 Electronic Control Module Wiring Harness is characterized by its robust design and the use of high-quality materials. It is constructed to endure the demanding conditions of commercial trucking, including exposure to vibrations, temperature extremes, and moisture. The harness incorporates advanced insulation and protective coatings to enhance its durability and performance. Additionally, it features precise connector designs to ensure secure and reliable connections 4.

Benefits

The integration of the 2864516 Electronic Control Module Wiring Harness into a truck’s electrical system offers several advantages. It contributes to improved engine performance by enabling precise control and monitoring of engine functions. The harness also enhances diagnostic capabilities, allowing for more accurate and efficient troubleshooting of electrical issues. Furthermore, it increases the reliability of the truck’s electrical system by providing a durable and secure connection between the ECM and other components 5.

Installation and Integration

Proper installation of the 2864516 Electronic Control Module Wiring Harness is crucial for its effective operation. It should be integrated into the truck’s electrical system according to the manufacturer’s guidelines to ensure compatibility and optimal performance. Specific requirements may include securing the harness in place to prevent damage from vibrations and ensuring all connections are secure and correctly aligned 6.

Troubleshooting and Maintenance

Regular maintenance and proper troubleshooting practices are important for the longevity and optimal performance of the 2864516 Electronic Control Module Wiring Harness. Inspections should be conducted to check for signs of wear, corrosion, or damage to the wires and connectors. Any issues identified should be addressed promptly to prevent further damage or system failures. Maintenance practices may include cleaning connectors and applying protective coatings as needed 7.

Common Issues and Solutions

Common issues with the 2864516 Electronic Control Module Wiring Harness may include loose connections, damaged wires, or corrosion on connectors. These issues can often be resolved by re-securing connections, repairing or replacing damaged wires, and cleaning or replacing corroded connectors. Preventive measures include regular inspections and maintenance to identify and address potential issues before they lead to system failures 8.

Cummins Overview

Cummins is a renowned manufacturer with a long-standing reputation in the automotive and heavy-duty truck industry. The company is known for its commitment to quality, innovation, and customer satisfaction. Cummins’ products, including the 2864516 Electronic Control Module Wiring Harness, are designed with a focus on durability, performance, and reliability, reflecting the company’s dedication to excellence in manufacturing automotive components 9.

Electronic Control Module Wiring Harness for Cummins Engines

The Electronic Control Module (ECM) Wiring Harness part number 2864516, manufactured by Cummins, is designed to integrate seamlessly with several of their engine models. This wiring harness plays a crucial role in ensuring the proper electrical connection between the ECM and various engine components, facilitating effective engine management and control.

ISM Series Engines

- ISM CM570

- ISM CM876

- ISM11 CM876 SN

The ISM series engines benefit from the ECM Wiring Harness 2864516, which ensures that the ECM can communicate effectively with the engine’s sensors and actuators. This harness is engineered to withstand the operational rigors of heavy-duty applications, providing reliable connectivity and minimizing the risk of electrical faults.

QSM Series Engines

- QSM11 CM570

- QSM11 CM876

Similar to the ISM series, the QSM11 engines also utilize the ECM Wiring Harness part number 2864516. This harness is critical for maintaining the integrity of the engine’s electronic control system, ensuring that the ECM can accurately monitor and control engine performance parameters. The harness is designed to fit precisely within the engine’s architecture, providing a secure and efficient electrical pathway.

By ensuring that the ECM Wiring Harness is correctly installed, engine reliability and performance can be significantly enhanced. This component is essential for maintaining the sophisticated electronic systems that modern engines depend on for optimal operation.

Role of Part 2864516 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, specifically part 2864516, is integral to the operation of modern engine systems. This harness serves as the vital link between the ECM and various engine components, facilitating communication and control.

Integration with Engine Control Components

-

Engine Control Module (ECM): The ECM is the brain of the engine system, responsible for processing data from various sensors and making real-time adjustments to engine performance. The ECM Wiring Harness ensures that the ECM receives accurate data from sensors and can send control signals to actuators.

-

Sensors: The harness connects a multitude of sensors, such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and Manifold Absolute Pressure (MAP) sensor. These sensors provide the ECM with essential data about air intake, fuel mixture, and engine load.

-

Actuators: Actuators like the fuel injectors, throttle body, and variable valve timing (VVT) solenoids are controlled via the ECM Wiring Harness. It transmits signals from the ECM to these components, allowing precise control over fuel delivery, air intake, and valve timing.

-

Power Supply: The harness also includes connections to the battery and ignition system, ensuring that the ECM and connected components receive the necessary power to operate.

-

Grounding: Proper grounding is essential for the reliable operation of the ECM and connected components. The ECM Wiring Harness includes grounding wires that connect to the engine block or chassis, ensuring a stable electrical environment.

-

Communication Networks: In many modern vehicles, the ECM is part of a larger communication network that includes other control modules (e.g., transmission control module, airbag control module). The ECM Wiring Harness may include connections to the Controller Area Network (CAN) bus, allowing for inter-module communication.

-

Diagnostic Connectors: The harness often includes connections to the On-Board Diagnostics (OBD) port, allowing technicians to access diagnostic trouble codes (DTCs) and perform system checks.

By seamlessly integrating these components, the ECM Wiring Harness ensures that the engine operates efficiently, meets emissions standards, and provides optimal performance.

Conclusion

The 2864516 Electronic Control Module Wiring Harness by Cummins is a critical component in the electrical system of commercial trucks. Its robust design, high-quality materials, and precise connector designs ensure reliable and efficient communication between the ECM and various engine components. Proper installation, regular maintenance, and prompt troubleshooting are essential for maximizing the performance and longevity of this Cummins part. By understanding its role and benefits, truck operators and maintenance professionals can ensure optimal engine performance and reliability.

-

Andrew Norman, Diesel Technology Fundamentals Service Repair Eighth Edition, The Goodheart-Willcox Company Inc, 2016.

↩ -

Thomas D. Gillespie, Fundamentals of Vehicle Dynamics, SAE International, 2021.

↩ -

Matthew Huang, Vehicle Crash Dynamics, CRC Press, 2002.

↩ -

Cummins, General Information, Bulletin Number 4915536, Owners Manual.

↩ -

Andrew Norman, Diesel Technology Fundamentals Service Repair Eighth Edition, The Goodheart-Willcox Company Inc, 2016.

↩ -

Cummins, General Information, Bulletin Number 4915536, Owners Manual.

↩ -

Andrew Norman, Diesel Technology Fundamentals Service Repair Eighth Edition, The Goodheart-Willcox Company Inc, 2016.

↩ -

Cummins, General Information, Bulletin Number 4915536, Owners Manual.

↩ -

Cummins, General Information, Bulletin Number 4915536, Owners Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.