2899741

Electronic Control Module Wiring Harness

Cummins®

DISCONTINUED

FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

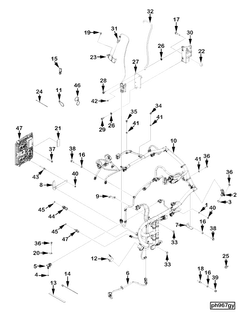

The Electronic Control Module Wiring Harness (part number 2899741) by Cummins is a vital component in the operation of heavy-duty trucks. Cummins, a renowned manufacturer in the automotive industry, has designed this wiring harness to enhance the functionality and efficiency of truck operations. This component is integral to the communication and control systems within heavy-duty trucks, ensuring optimal performance and reliability.

Basic Concepts

The Electronic Control Module (ECM) serves as the brain of the truck, managing various operations and ensuring that all systems work in harmony. It processes data from sensors throughout the vehicle and makes real-time adjustments to improve performance and efficiency. The wiring harness is a network of wires and connectors that link the ECM to different components of the truck, facilitating the transmission of data and electrical signals necessary for the ECM to function effectively.

Purpose of the Electronic Control Module Wiring Harness

The Electronic Control Module Wiring Harness plays a significant role in the operation of a truck by enabling seamless communication between the ECM and various truck components. It ensures that the ECM receives accurate data from sensors and can send appropriate signals to actuators, thereby maintaining the truck’s performance and efficiency. This harness is designed to withstand the harsh conditions typically encountered in heavy-duty truck operations, ensuring reliable and consistent performance.

Key Features

The Electronic Control Module Wiring Harness is characterized by its robust design and high-quality materials. It is constructed using durable wires and connectors that are resistant to corrosion, abrasion, and extreme temperatures. The harness is also designed with a modular structure, allowing for easy installation and maintenance. Additionally, it features advanced shielding to protect against electromagnetic interference, ensuring signal integrity and reliable data transmission.

Benefits

Utilizing the Electronic Control Module Wiring Harness offers several advantages. It contributes to improved engine performance by ensuring that the ECM receives accurate data and can make precise adjustments. Enhanced diagnostic capabilities are another benefit, as the harness allows for more effective monitoring and troubleshooting of truck systems. Furthermore, the harness increases the overall reliability of the truck by providing a stable and secure connection between the ECM and other components.

Installation Process

Installing the Electronic Control Module Wiring Harness involves several steps. First, ensure that the truck is turned off and the battery is disconnected to prevent any electrical accidents. Next, route the harness through the designated pathways in the truck, ensuring that it is securely fastened and protected from potential damage. Connect the harness to the ECM and other components, following the manufacturer’s instructions carefully. Finally, reattach the battery and test the system to ensure that all connections are secure and functioning correctly.

Troubleshooting and Maintenance

Common issues with the Electronic Control Module Wiring Harness may include loose connections, damaged wires, or corrosion. To troubleshoot these issues, inspect the harness regularly for any signs of wear or damage. Ensure that all connections are secure and free from corrosion. Maintenance tips include keeping the harness clean and dry, avoiding exposure to harsh chemicals, and regularly checking for any signs of wear or damage. Promptly addressing any issues will help ensure the longevity and optimal performance of the harness.

Integration With Other Systems

The Electronic Control Module Wiring Harness interacts with various truck systems, including the engine, transmission, and braking systems. It facilitates the exchange of data and electrical signals between these systems and the ECM, ensuring that all components work together seamlessly. This integration enhances the overall performance and efficiency of the truck, allowing for better control and management of all systems.

Technological Advancements

The Electronic Control Module Wiring Harness incorporates several technological innovations that enhance its performance and reliability. These include advanced materials that offer superior resistance to environmental factors, improved shielding to protect against electromagnetic interference, and a modular design that simplifies installation and maintenance. These advancements ensure that the harness can withstand the demanding conditions of heavy-duty truck operations while providing consistent and reliable performance.

Cummins Overview

Cummins is a leading manufacturer in the automotive industry, known for its high-quality components and innovative solutions. With a rich history of expertise and a strong reputation for reliability, Cummins continues to push the boundaries of technology to provide superior products for the automotive market. Their commitment to quality and innovation is evident in the design and performance of the Electronic Control Module Wiring Harness, making it a trusted component for heavy-duty truck operations.

Understanding the Role of Part 2899741 in Engine Systems

The Electronic Control Module (ECM) Wiring Harness (part 2899741) is integral to the operation of modern engine systems. This harness serves as the vital link between the ECM and various engine components, facilitating the transmission of electrical signals that are essential for engine management.

Integration with Engine Components

-

Engine Control Module (ECM): The ECM is the brain of the engine system, responsible for processing data from various sensors and making real-time adjustments to engine performance. The ECM Wiring Harness connects directly to the ECM, allowing it to communicate with other components.

-

Sensors: Modern engines are equipped with numerous sensors that monitor parameters such as temperature, pressure, and airflow. The harness routes signals from these sensors to the ECM, enabling precise control over engine functions.

-

Actuators: Actuators, such as fuel injectors and ignition coils, rely on signals from the ECM to operate. The wiring harness transmits these signals, ensuring that the actuators perform their functions at the correct times.

-

Power Supply: The harness also includes connections to the vehicle’s power supply, ensuring that the ECM and other electronic components receive the necessary voltage to operate efficiently.

-

Grounding: Proper grounding is essential for the reliable operation of electronic systems. The harness includes grounding wires that connect to the vehicle’s chassis, providing a stable reference point for electrical signals.

Functionality in Engine Systems

-

Data Transmission: The ECM Wiring Harness enables the seamless transmission of data between the ECM and various engine components. This ensures that the ECM can make informed decisions based on real-time data.

-

System Integration: By connecting disparate components into a cohesive network, the harness allows for integrated engine management. This results in improved performance, efficiency, and reliability.

-

Diagnostic Capabilities: The harness also plays a role in diagnostic systems, allowing technicians to access data from the ECM and other components for troubleshooting and maintenance purposes.

Conclusion

In summary, the ECM Wiring Harness (part 2899741) is a fundamental component in modern engine systems, ensuring that all electronic elements work in harmony to deliver optimal engine performance. Its robust design, advanced features, and integration capabilities make it an essential part of heavy-duty truck operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.