FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3082610 Electronic Control Module Wiring Harness is a critical component in the operation of commercial trucks. It serves as the conduit for electrical signals between the Electronic Control Module (ECM) and various electronic components within the truck. This wiring harness ensures seamless communication and coordination among the truck’s electronic systems, contributing to efficient and reliable performance.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a network of wires and connectors designed to facilitate the transmission of electrical signals. It plays a role in the electronic system of a truck by linking the ECM to sensors, actuators, and other electronic devices. This interconnection allows for the monitoring and control of various truck functions, such as engine performance, transmission operations, and emissions management 1.

Purpose of the 3082610 Electronic Control Module Wiring Harness

The 3082610 Wiring Harness is integral to the operation of a truck. It enables the ECM to receive data from sensors and send commands to actuators, ensuring that the truck operates within optimal parameters. This harness interacts with the ECM and other electronic components to maintain engine efficiency, regulate emissions, and enhance overall vehicle performance.

Key Features

The 3082610 Wiring Harness is characterized by its robust design and high-quality build. It features durable materials that resist wear and environmental factors, ensuring long-lasting performance. Additionally, the harness is engineered with precision to fit seamlessly into the truck’s electronic system, minimizing the risk of errors or malfunctions.

Benefits

The 3082610 Wiring Harness offers several benefits, including improved reliability and enhanced performance. By ensuring stable and efficient communication between the ECM and other components, it contributes to the truck’s overall reliability. Furthermore, its high-quality construction can lead to potential cost savings for fleet operators by reducing the need for frequent repairs or replacements 2.

Installation Process

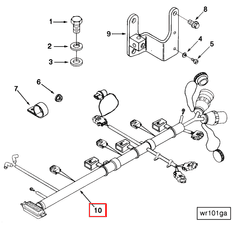

Installing the 3082610 Wiring Harness involves several steps. First, ensure that the truck’s electrical system is powered down to avoid any risk of electrical shock. Next, locate the existing wiring harness and disconnect it from the ECM and other components. Carefully route the new 3082610 Wiring Harness through the truck, following the manufacturer’s guidelines for proper placement. Connect the harness to the ECM and other electronic components, ensuring all connections are secure. Finally, power up the electrical system and test the harness to confirm proper installation.

Troubleshooting Common Issues

Common issues with the 3082610 Wiring Harness may include loose connections, damaged wires, or faulty connectors. To troubleshoot these problems, begin by inspecting the harness for any visible signs of damage. Check all connections to ensure they are secure and free from corrosion. If issues persist, use a multimeter to test the continuity of the wires and identify any breaks or shorts. Addressing these issues promptly can help maintain the harness’s performance and reliability.

Maintenance Tips

To ensure the longevity and optimal performance of the 3082610 Wiring Harness, regular maintenance is crucial. Inspect the harness periodically for signs of wear, damage, or corrosion. Clean the connectors to remove any dirt or debris that may interfere with signal transmission. Additionally, protect the harness from physical damage by securing it properly within the truck’s chassis. Following these maintenance practices can help extend the life of the wiring harness and ensure consistent performance.

Safety Considerations

When working with the 3082610 Wiring Harness, it is important to observe electrical safety practices. Always ensure that the truck’s electrical system is powered down before beginning any work on the harness. Use insulated tools to avoid electrical shocks and wear protective gear, such as gloves and safety glasses. Additionally, take care to avoid damaging the harness during installation or maintenance to prevent electrical malfunctions.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins has established itself as a trusted name in the commercial truck industry. The company’s focus on technological advancement and customer satisfaction has made it a preferred choice for fleet operators worldwide.

Role of Part 3082610 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified by part number 3082610, serves as the backbone for the electrical communication within engine systems. This harness is integral in connecting the ECM to various components, ensuring seamless data transmission and power distribution.

Integration with Accessories

The ECM Wiring Harness is responsible for linking the ECM to a multitude of accessories within the engine system. These accessories include sensors, actuators, and other control devices that are essential for the engine’s operation. By providing a robust and reliable connection, the harness ensures that these accessories receive the necessary signals and power to function correctly. This integration allows for precise control over engine parameters such as fuel injection, ignition timing, and emissions control.

Wiring Coordination

In terms of wiring, the ECM Wiring Harness plays a pivotal role in organizing and protecting the electrical cables that run throughout the engine system. It routes power and data lines from the ECM to various points within the engine, including the fuel injectors, ignition coils, and throttle position sensor. This organized approach minimizes the risk of electrical interference and ensures that each component receives a consistent and accurate signal. The harness also incorporates protective measures such as shielding and insulation to safeguard the wires from physical damage and environmental factors.

Enhanced System Performance

By facilitating efficient communication between the ECM and the engine’s components, the ECM Wiring Harness contributes to enhanced system performance. It allows for real-time monitoring and adjustment of engine operations, leading to improved fuel efficiency, reduced emissions, and overall better engine performance. The harness’s design also supports diagnostic capabilities, enabling mechanics to quickly identify and address any issues within the engine system 3.

Conclusion

In summary, the ECM Wiring Harness (part 3082610) is a fundamental component in the engine system, ensuring that all electrical connections are secure, organized, and efficient. Its role in connecting the ECM to accessories and wiring is essential for the proper functioning and performance of the engine.

-

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.