3411481

Electronic Control Module Wiring Harness

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

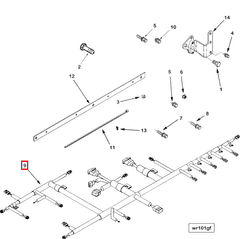

The Electronic Control Module Wiring Harness (Part #3411481) by Cummins is a vital component in the operation of commercial trucks. This wiring harness facilitates the communication between the Electronic Control Module (ECM) and various sensors and actuators throughout the vehicle. Its purpose is to ensure that the ECM receives accurate data from sensors and can effectively control the truck’s systems, contributing to overall performance and efficiency 1.

Basic Concepts

Electronic Control Module Wiring Harnesses are integral to vehicle electronics and communication systems. They consist of a network of wires and connectors that link the ECM to other electronic components. These harnesses enable the transmission of data and power, allowing the ECM to monitor and adjust the truck’s operations in real-time. Understanding the principles behind these harnesses is fundamental to grasping their role in modern vehicle electronics 2.

Functionality

The Electronic Control Module Wiring Harness operates by providing a structured pathway for electrical signals and power between the ECM and other components within the truck’s electronic system. It interacts with sensors that collect data on various parameters such as engine temperature, fuel levels, and emissions. This data is then sent to the ECM, which processes the information and sends commands back through the harness to actuators that make adjustments to the truck’s systems. This continuous loop of communication ensures that the truck operates efficiently and within specified parameters.

Role in Truck Operation

The 3411481 Electronic Control Module Wiring Harness plays a specific role in the overall operation and performance of commercial trucks. By enabling seamless communication between the ECM and other electronic components, it ensures that the truck’s systems are monitored and controlled effectively. This contributes to the truck’s reliability, performance, and efficiency, making it a cornerstone of modern commercial vehicle technology.

Key Features

The primary features of the 3411481 Electronic Control Module Wiring Harness include its robust design and construction, which are tailored to withstand the harsh environments typical of commercial truck operations. It is engineered with high-quality materials to ensure durability and reliability. Additionally, the harness may include unique attributes such as corrosion-resistant connectors and enhanced shielding to protect against electromagnetic interference, further ensuring its longevity and performance.

Benefits

The advantages provided by the 3411481 Electronic Control Module Wiring Harness include improved efficiency, reliability, and performance of the truck’s electronic systems. By ensuring accurate and timely communication between the ECM and other components, it helps maintain optimal operation of the truck. This can lead to better fuel efficiency, reduced emissions, and enhanced overall performance, contributing to the truck’s productivity and longevity.

Troubleshooting and Maintenance

Common issues that may arise with the Electronic Control Module Wiring Harness include damaged wires, corroded connectors, and faulty sensors or actuators. Recommended troubleshooting steps involve inspecting the harness for visible damage, ensuring all connections are secure and clean, and using diagnostic tools to identify any electronic faults. Regular maintenance practices include cleaning connectors, checking for wear and tear, and replacing any damaged sections of the harness to prevent future issues.

About Cummins

Cummins is a renowned manufacturer with a rich history in the commercial truck industry. Known for its high-quality engines and components, Cummins has established a strong reputation for reliability and performance. The company’s involvement in the industry spans decades, during which it has consistently innovated to meet the evolving needs of commercial transportation, making it a trusted name among fleet operators and truck manufacturers alike.

N14 CELECT PLUS Engine Family

The Electronic Control Module (ECM) Wiring Harness, part number 3411481, is a critical component in the N14 CELECT PLUS engine family. This wiring harness is designed to facilitate seamless communication between the ECM and various engine sensors and actuators. It ensures that the ECM can effectively monitor and control engine performance, emissions, and overall functionality.

The harness is meticulously engineered to withstand the harsh conditions of engine compartments, including high temperatures, vibrations, and exposure to engine fluids. Its robust construction and precise wiring ensure reliable signal transmission, which is essential for the engine’s optimal operation.

In the N14 CELECT PLUS engine, the ECM Wiring Harness connects the ECM to critical components such as the fuel injectors, turbocharger, and exhaust gas recirculation (EGR) valve. This connectivity is vital for maintaining the engine’s efficiency and compliance with emissions standards.

The harness is designed to be easily integrated into the engine’s existing wiring architecture, allowing for straightforward installation and maintenance. Its compatibility with the N14 CELECT PLUS engine ensures that it can be used across various applications, from heavy-duty trucks to industrial power systems.

Role of Part 3411481 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified by part number 3411481, serves as the vital connective tissue within an engine’s electronic system. This harness is responsible for facilitating communication and power distribution between the ECM and various engine components.

Incorporating the ECM Wiring Harness into an engine system ensures that the ECM can effectively monitor and control engine operations. It connects to sensors such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and Manifold Absolute Pressure (MAP) sensor, allowing the ECM to receive real-time data on air intake, fuel mixture, and engine load.

The harness also interfaces with actuators including the fuel injectors, throttle body, and various solenoids. This connection enables the ECM to adjust fuel delivery, air intake, and other parameters to optimize engine performance and efficiency.

Additionally, the ECM Wiring Harness links to the engine’s ignition system, including the coil packs and spark plugs. This ensures precise timing of ignition events, which is essential for combustion efficiency and overall engine reliability.

In summary, the ECM Wiring Harness is integral to the functioning of modern engine systems, providing the necessary pathways for data and power that allow the ECM to manage and fine-tune engine operations.

Conclusion

The 3411481 Electronic Control Module Wiring Harness by Cummins is a critical component in the operation of commercial trucks and the N14 CELECT PLUS engine family. Its robust design, key features, and role in facilitating communication between the ECM and various engine components ensure the reliability, performance, and efficiency of the truck’s electronic systems. Regular maintenance and troubleshooting are essential to keep this part functioning optimally, contributing to the overall productivity and longevity of the vehicle.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.