FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

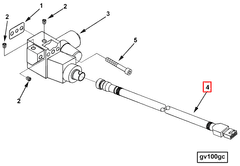

The 3681060 Electronic Control Module Wiring Harness is a component manufactured by Cummins, a well-established name in the automotive industry. This wiring harness is significant in the operation of commercial trucks, facilitating the communication and power distribution necessary for the truck’s electronic systems to function correctly.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a collection of wires and connectors that link various electronic components within a truck’s electrical system. It serves as the nervous system of the vehicle, allowing the Electronic Control Module (ECM) to communicate with and control other systems. The harness includes wires of varying gauges, connectors, and protective sheathing, all designed to withstand the harsh conditions found in commercial trucking environments 1.

Role of the 3681060 Wiring Harness in Truck Operation

The 3681060 Wiring Harness plays a specific role in the operation of a truck by providing the necessary connections between the ECM and other electronic components. It ensures that signals and power are correctly routed, allowing the ECM to monitor and adjust engine performance, transmission operations, and other critical systems. This harness is integral to the truck’s ability to operate efficiently and reliably 2.

Key Features of the 3681060 Wiring Harness

The 3681060 Wiring Harness is designed with several key features that enhance its performance and durability. It is constructed using high-quality materials resistant to wear, corrosion, and the extreme temperatures often encountered in commercial trucking. The design of the harness includes robust connectors and protective sheathing to ensure longevity and reliability. Additionally, the harness is engineered to be easy to install, reducing downtime during maintenance or repair procedures 3.

Benefits of Using the 3681060 Wiring Harness

Using the 3681060 Wiring Harness offers several benefits. Its high-quality construction and design contribute to improved reliability and efficiency of the truck’s electronic systems. The ease of installation reduces maintenance time, allowing trucks to return to service more quickly. Furthermore, the durability of the harness means fewer replacements are needed over the life of the vehicle, contributing to cost savings.

Troubleshooting the 3681060 Wiring Harness

When troubleshooting the 3681060 Wiring Harness, it is important to follow a systematic approach. Begin by identifying any symptoms of malfunction, such as erratic engine behavior or warning lights on the dashboard. Inspect the harness for visible signs of damage, such as frayed wires or corroded connectors. Diagnostic tools can be used to test the electrical continuity and identify any breaks or shorts within the harness. Addressing issues promptly can prevent more severe problems and ensure the truck’s continued reliable operation.

Maintenance of the 3681060 Wiring Harness

Maintaining the 3681060 Wiring Harness is crucial for ensuring its optimal performance and longevity. Regular inspections should be conducted to check for signs of wear, damage, or corrosion. Cleaning the harness and its connectors can prevent the buildup of dirt and debris, which can lead to poor connections. Additionally, ensuring that the harness is properly secured and protected from physical damage will help maintain its integrity over time.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer in the automotive industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance components, Cummins has established a strong reputation among commercial truck operators and maintenance professionals. The company’s dedication to excellence is evident in its products, including the 3681060 Wiring Harness, which is designed to meet the demanding requirements of commercial trucking applications.

Cummins Engine Compatibility with Part 3681060

The Electronic Control Module (ECM) Wiring Harness, part number 3681060, manufactured by Cummins, is a critical component for the proper functioning of the engine’s electronic systems. This wiring harness is designed to ensure seamless communication between the ECM and various sensors and actuators within the engine. It is essential for the optimal performance and reliability of the engine.

ISX CM570 and ISX CM870 Engines

For the ISX CM570 and ISX CM870 engines, the ECM Wiring Harness (part 3681060) plays a pivotal role in the engine’s electronic management system. Both engines are part of Cummins’ ISX series, known for their robust performance and efficiency. The wiring harness is engineered to fit precisely within the architecture of these engines, ensuring that all electronic signals are transmitted accurately and efficiently.

The harness is designed to withstand the harsh operating conditions typical of these engines, including high temperatures and vibrations. Its robust construction ensures longevity and reliability, reducing the likelihood of electrical faults that could lead to engine downtime.

The part number 3681060 is specifically tailored to interface with the ECM of the ISX CM570 and ISX CM870 engines, providing a standardized solution for these models. This compatibility ensures that the engine’s electronic systems can operate without issues, maintaining the engine’s performance and efficiency.

Role of Part 3681060 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, specifically part 3681060, is integral to the operation of various engine components, ensuring seamless communication and functionality.

Integration with the Governor

The governor is a device that regulates the speed of an engine. The ECM Wiring Harness connects the governor to the ECM, allowing for precise control over engine speed. This connection enables the ECM to receive real-time data from the governor, adjusting fuel delivery and ignition timing to maintain optimal performance. The harness facilitates the transmission of signals that inform the ECM of the governor’s adjustments, ensuring that the engine operates within the desired parameters.

Connection to the Air Compressor

In engine systems equipped with an air compressor, the ECM Wiring Harness plays a significant role in managing the compressor’s operation. The harness links the air compressor to the ECM, enabling the ECM to monitor and control the compressor’s activity. This ensures that the air compressor operates efficiently, providing the necessary air pressure for various engine functions without overloading the system. The ECM can adjust the compressor’s operation based on the engine’s demand, enhancing overall engine performance and reliability.

Overall Functionality

By integrating with components like the governor and air compressor, the ECM Wiring Harness ensures that the ECM receives accurate data and can make informed decisions to optimize engine performance. This robust communication network allows for dynamic adjustments to engine parameters, contributing to enhanced efficiency, reduced emissions, and improved durability. The harness’s role in facilitating these connections underscores its importance in modern engine management systems.

Conclusion

The 3681060 Electronic Control Module Wiring Harness is a critical component in the operation of commercial trucks and Cummins engines, ensuring seamless communication and power distribution among electronic systems. Its high-quality construction, ease of installation, and durability contribute to the reliability and efficiency of the vehicle. Regular maintenance and prompt troubleshooting are essential to maximize the lifespan and performance of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.