FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3681115 Electronic Control Module (ECM) Wiring Harness by Cummins is a vital component in the electrical system of commercial trucks. It facilitates communication between the ECM and various sensors, actuators, and other electronic components within the truck. This harness ensures that the ECM receives accurate data and can effectively control the truck’s systems, contributing to overall performance and reliability.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a network of wires and connectors designed to link the ECM to other electronic components in the truck. It consists of multiple wires, each serving a specific function, bundled together for protection and organization. The harness allows for the transmission of data and power between the ECM and components such as sensors, actuators, and other control units. This system ensures that the ECM can monitor and adjust the truck’s operations in real-time 1.

Role of the 3681115 Electronic Control Module Wiring Harness in Truck Operation

The 3681115 Wiring Harness plays a significant role in the operation of a truck by enabling the ECM to interact with various systems and components. It allows the ECM to receive input from sensors regarding engine performance, transmission status, and other critical parameters. Based on this data, the ECM can make adjustments to optimize fuel efficiency, enhance performance, and ensure the truck operates within safe parameters. The harness also facilitates the ECM’s control over actuators, which perform actions such as adjusting the fuel injection timing or engaging the transmission 2.

Key Features of the 3681115 Wiring Harness

The 3681115 Wiring Harness is distinguished by its robust design and high-quality build. It is engineered to withstand the harsh conditions often encountered in commercial trucking, including vibrations, temperature fluctuations, and exposure to chemicals. The harness is constructed using durable materials and precision-engineered connectors to ensure reliable performance. Additionally, it is designed for easy integration with Cummins ECMs, ensuring compatibility and seamless operation.

Benefits of Using the 3681115 Wiring Harness

Incorporating the 3681115 Wiring Harness into a truck’s electrical system offers several advantages. It enhances the reliability of the electrical connections, reducing the risk of malfunctions and improving overall system performance. The harness contributes to better fuel efficiency by enabling the ECM to make precise adjustments based on real-time data. Additionally, it supports diagnostic capabilities, allowing for easier identification and resolution of issues, which can lead to reduced downtime and maintenance costs.

Installation Considerations

When installing the 3681115 Wiring Harness, it is important to follow guidelines and best practices to ensure proper integration and functionality. This may include ensuring the truck’s electrical system is compatible with the harness, using the appropriate tools for installation, and following the manufacturer’s instructions. It is also advisable to perform a system check after installation to verify that all connections are secure and that the ECM is receiving accurate data from the connected components.

Troubleshooting Common Issues

Common problems that may arise with the 3681115 Wiring Harness include loose connections, damaged wires, or faulty connectors. To diagnose these issues, it is recommended to perform a visual inspection of the harness for any signs of wear or damage. Using diagnostic tools can help identify specific problems within the electrical system. Addressing these issues promptly can prevent more significant problems and ensure the continued reliable operation of the truck.

Maintenance Tips

To ensure the longevity and optimal performance of the 3681115 Wiring Harness, regular maintenance is recommended. This includes periodic inspections for signs of wear, corrosion, or damage. Cleaning the harness and its connections can prevent the buildup of dirt and debris, which can interfere with electrical conductivity. Additionally, ensuring that all connections are tight and secure can help maintain the integrity of the electrical system.

Safety Precautions

When working with the 3681115 Wiring Harness, it is important to observe electrical safety practices. This includes ensuring the truck’s battery is disconnected before beginning any work to prevent the risk of electrical shock. Using insulated tools and wearing appropriate personal protective equipment can further enhance safety. It is also important to handle the harness with care to avoid damaging the wires or connectors.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engines and components. The company’s commitment to innovation and quality has made it a preferred choice for commercial truck operators worldwide.

Role of Part 3681115 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified by part number 3681115, is integral to the seamless operation of various engine systems. It serves as the vital link that facilitates communication and power distribution among several key components.

Integration with Fuel System

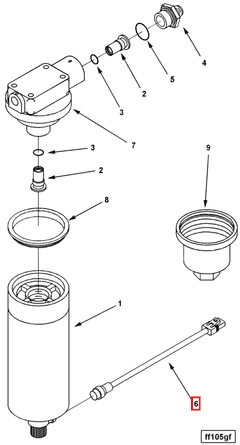

In the fuel system, the ECM Wiring Harness connects the ECM to the fuel injectors, fuel pump, and fuel pressure sensors. This connection ensures that the ECM can precisely control fuel delivery based on real-time data from sensors, optimizing fuel efficiency and engine performance. The harness also interfaces with the fuel filter, allowing the ECM to monitor fuel quality and adjust fuel delivery parameters accordingly.

Connection to Remote Filter Head Kit

When a remote filter head kit is installed, the ECM Wiring Harness extends its reach to include the additional components of this setup. It links the ECM to the remote fuel filter and associated sensors, enabling the ECM to maintain optimal fuel filtration and pressure. This extension ensures that the remote filter head kit operates in harmony with the engine’s fuel management system, enhancing overall engine reliability and performance.

Interaction with Engine Filter

The ECM Wiring Harness also plays a role in the engine’s filtration system by connecting the ECM to the engine filter sensors. This allows the ECM to monitor the condition of the engine filter and adjust engine parameters to compensate for any changes in filtration efficiency. By maintaining a consistent flow of clean air to the engine, the harness contributes to the engine’s longevity and operational stability.

Conclusion

In summary, the ECM Wiring Harness (part 3681115) is a fundamental component that ensures the ECM can effectively manage and optimize the performance of the fuel system, remote filter head kit, and engine filter within the engine system. Its robust design, compatibility with various Cummins engines, and integration with advanced diagnostic systems make it an essential part of maintaining optimal engine performance and efficiency.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.