FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

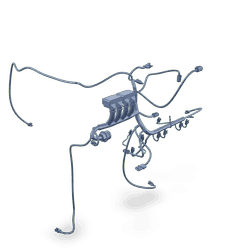

The 3681433 Electronic Control Module Wiring Harness is a component manufactured by Cummins, a well-established name in the commercial truck industry. This wiring harness is integral to the operation of commercial trucks, facilitating the communication between the electronic control module (ECM) and various sensors and actuators throughout the vehicle.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a network of wires and connectors that link the ECM to other electronic components within the truck. It consists of multiple wires, each serving a specific function, bundled together for organized routing. The harness ensures that electrical signals are transmitted accurately and efficiently, allowing the ECM to monitor and control various truck systems 1.

Role of the 3681433 Electronic Control Module Wiring Harness in Truck Operation

The 3681433 Wiring Harness plays a significant role in the operation of a commercial truck by enabling the ECM to interact with other systems and components. It allows the ECM to receive data from sensors and send commands to actuators, thereby managing engine performance, transmission operations, and other critical functions. This interaction ensures that the truck operates smoothly and efficiently 2.

Key Features of the 3681433 Wiring Harness

The 3681433 Wiring Harness is designed with several key features that enhance its functionality and durability. It is constructed using high-quality materials that are resistant to wear and environmental factors. The harness is engineered to fit precisely within the truck’s existing framework, ensuring a secure and reliable connection. Additionally, it includes protective coatings and shielding to prevent interference and damage from external elements.

Benefits of Using the 3681433 Wiring Harness

Utilizing the 3681433 Wiring Harness offers several advantages. It contributes to improved efficiency by ensuring that electrical signals are transmitted without loss or interference. The harness enhances the reliability of the truck’s electronic systems, leading to better overall performance. Furthermore, its robust design helps in reducing the likelihood of electrical faults, thereby minimizing downtime and maintenance costs.

Installation Considerations

Proper installation of the 3681433 Wiring Harness is vital to ensure its effective operation. It is important to follow the manufacturer’s guidelines, which may include specific routing paths and connection points. Ensuring that all connections are secure and that the harness is properly grounded will help in maintaining the integrity of the electrical system. Additionally, any existing wiring should be inspected for damage or wear before installation.

Troubleshooting Common Issues

Identifying and resolving common problems with the 3681433 Wiring Harness can be achieved through systematic diagnostic steps. Issues may arise from loose connections, damaged wires, or environmental factors affecting the harness. Regular inspections can help in early detection of potential problems. Diagnostic tools can be used to trace electrical signals and identify any irregularities within the harness.

Maintenance Tips

Regular maintenance of the 3681433 Wiring Harness is recommended to ensure its longevity and optimal performance. This includes routine inspections for signs of wear, corrosion, or damage. Cleaning the harness and ensuring that all connections remain tight and secure will help in preventing issues. Additionally, protecting the harness from physical damage and environmental factors will contribute to its durability.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of products including engines, filtration systems, and aftermarket parts. With a history of innovation and quality, Cummins has established a strong reputation for reliability and performance. The company’s commitment to excellence is reflected in its products, including the 3681433 Electronic Control Module Wiring Harness.

Electronic Control Module Wiring Harness for Cummins Engines

The Electronic Control Module (ECM) Wiring Harness, part number 3681433, is a critical component in ensuring the seamless operation of Cummins engines. This wiring harness is meticulously designed to interface with the ECM, facilitating the transmission of electrical signals that govern the engine’s performance and diagnostics.

ISX CM570

For the ISX CM570 engine, the ECM Wiring Harness is integral to the engine’s electronic control system. It connects the ECM to various sensors and actuators, ensuring that the engine’s operational parameters are continuously monitored and adjusted. This harness is engineered to withstand the rigors of heavy-duty applications, providing reliable connectivity and signal integrity.

Grouping of Engines

The ECM Wiring Harness is compatible with a range of Cummins engines, including but not limited to, the ISX series. This compatibility extends to other models within the Cummins lineup, ensuring that the harness can be utilized across different engine types. The design and construction of the harness are standardized to fit various engine configurations, making it a versatile component in Cummins’ engine ecosystem.

The harness’s robust construction and precise wiring ensure that it can handle the demanding conditions of heavy-duty operations. Its design prioritizes durability and reliability, which are essential for maintaining the performance and longevity of the engine. The harness is also engineered to minimize electromagnetic interference, ensuring that the ECM receives accurate and uninterrupted signals.

Understanding the Integration of Part 3681433 Electronic Control Module Wiring Harness in Engine Systems

The part 3681433 electronic control module wiring harness is an essential component in the orchestration of modern engine systems. This wiring harness serves as the vital conduit that facilitates communication and power distribution between the engine control module (ECM) and various engine components.

Role in Engine Systems

-

Engine Control Module (ECM) Communication: The wiring harness establishes a robust communication link between the ECM and other engine components. This ensures that the ECM can effectively monitor and control engine operations, adjusting parameters such as fuel injection, ignition timing, and emissions controls in real-time.

-

Sensor Data Transmission: It relays data from various sensors—such as the mass airflow sensor, oxygen sensors, and throttle position sensor—to the ECM. This data is critical for the ECM to make informed decisions regarding engine performance and efficiency.

-

Actuator Control: The harness also transmits signals from the ECM to actuators, including fuel injectors, ignition coils, and variable valve timing solenoids. This allows the ECM to execute precise control over these components, optimizing engine performance and fuel economy.

-

Power Distribution: Beyond communication, the wiring harness distributes electrical power to essential engine components. This includes supplying voltage to sensors, actuators, and even the ECM itself, ensuring that all systems have the necessary power to function correctly.

-

Integration with Ancillary Systems: In more complex engine systems, the harness may also interface with ancillary systems such as the transmission control module, anti-lock braking system, and even the vehicle’s onboard diagnostics system. This integration allows for a cohesive operation of the vehicle’s various subsystems, enhancing overall performance and drivability.

Conclusion

In summary, the 3681433 electronic control module wiring harness is indispensable in modern engine systems. It ensures seamless communication and power distribution, allowing the ECM to maintain optimal engine performance and efficiency.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.