FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

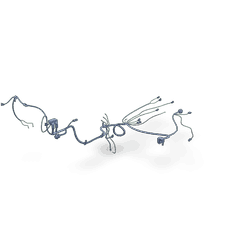

The 3681451 Electronic Control Module Wiring Harness is a component manufactured by Cummins, a well-established name in the commercial truck industry. This wiring harness is integral to the operation of commercial trucks, facilitating the communication between the electronic control module (ECM) and various sensors and actuators throughout the vehicle.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a network of wires and connectors that links the ECM to the truck’s electrical system. It comprises several components, including wires, connectors, and terminals. The harness functions by transmitting signals and power between the ECM and other electronic components, ensuring that the truck’s systems operate in harmony 1.

Role of the 3681451 Electronic Control Module Wiring Harness in Truck Operation

The 3681451 Electronic Control Module Wiring Harness plays a significant role in the operation of a commercial truck. It enables the ECM to receive data from various sensors and send commands to actuators, thereby controlling critical functions such as engine performance, transmission shifting, and emissions control. The harness also interacts with other systems, including the engine, transmission, and braking systems, to ensure seamless operation 2.

Key Features of the 3681451 Electronic Control Module Wiring Harness

The 3681451 Electronic Control Module Wiring Harness is designed with several key features that enhance its performance and reliability. These include robust construction for durability, a design that ensures efficient signal transmission, and integration capabilities that allow it to interface with various truck systems. The harness is also engineered to withstand the harsh conditions typically encountered in commercial trucking 3.

Benefits of Using the 3681451 Electronic Control Module Wiring Harness

Utilizing the 3681451 Electronic Control Module Wiring Harness offers several benefits. It contributes to improved truck performance by ensuring accurate and timely communication between the ECM and other components. The harness also enhances reliability by minimizing the risk of electrical faults and improving overall system efficiency. Additionally, it supports efficient diagnostics and troubleshooting, which can reduce downtime and maintenance costs.

Installation Considerations

Proper installation of the 3681451 Electronic Control Module Wiring Harness is vital to ensure optimal performance and longevity. Best practices include following the manufacturer’s guidelines, ensuring all connections are secure, and protecting the harness from physical damage and environmental factors. Potential challenges may include routing the harness through tight spaces and ensuring compatibility with the truck’s existing electrical system.

Troubleshooting Common Issues

Common issues with the 3681451 Electronic Control Module Wiring Harness may include loose connections, damaged wires, or faulty connectors. Troubleshooting steps involve inspecting the harness for visible damage, checking connections for security, and using diagnostic tools to identify any electrical faults. Addressing these issues promptly can prevent more significant problems and ensure the truck operates efficiently.

Maintenance Tips

Regular maintenance of the 3681451 Electronic Control Module Wiring Harness is essential to ensure its longevity and optimal performance. Maintenance tips include periodic inspection for signs of wear or damage, ensuring all connections remain secure, and protecting the harness from environmental factors. Additionally, keeping the harness clean and free from debris can prevent corrosion and other issues.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its innovative products, commitment to quality, and extensive support services. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding needs of commercial trucking.

Compatibility with Cummins Engines

The Electronic Control Module (ECM) Wiring Harness, part number 3681451, is designed to integrate seamlessly with Cummins engines, including the ISX CM570. This engine is known for its robust performance and reliability, making it a popular choice in heavy-duty applications. The harness ensures that the ECM can accurately monitor and control the engine’s operations, enhancing efficiency and longevity.

Importance of the ECM Wiring Harness

The ECM Wiring Harness is essential for maintaining the integrity of the engine’s electronic control system. It ensures that all necessary signals are transmitted accurately and efficiently, which is crucial for the engine’s performance and diagnostic capabilities. Proper installation and maintenance of this harness can prevent a multitude of issues, from minor performance hiccups to more severe failures.

Installation and Maintenance

Proper installation of the ECM Wiring Harness is critical to ensure that the engine operates at peak efficiency. Technicians should follow the manufacturer’s guidelines to avoid any potential issues. Regular maintenance checks can help identify any wear or damage to the harness, allowing for timely repairs and preventing potential downtime.

Role of Part 3681451 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified by part number 3681451, is integral to the operation of modern engine systems. This harness serves as the vital link between the ECM and various electrical accessories and components within the engine system.

Integration with Electrical Accessories

The ECM Wiring Harness facilitates the connection between the ECM and a multitude of electrical accessories. These accessories include, but are not limited to, fuel injectors, ignition coils, sensors (such as the Mass Air Flow sensor and Oxygen sensor), and actuators (like the throttle position actuator and variable valve timing solenoid).

Communication and Signal Transmission

This harness is responsible for transmitting signals from the ECM to these accessories, ensuring that they operate in accordance with the ECM’s commands. For instance, when the ECM determines that more fuel is needed for optimal combustion, it sends a signal through the wiring harness to the fuel injectors, instructing them to deliver the appropriate amount of fuel.

Power Distribution

In addition to signal transmission, the ECM Wiring Harness also plays a role in power distribution. It supplies power to various components from the battery or other power sources, ensuring that all electrical accessories have the necessary voltage to function correctly.

Diagnostic and Feedback Loop

The harness also enables a feedback loop between the ECM and the engine’s sensors. Sensors continuously monitor various parameters such as engine temperature, air-fuel ratio, and engine speed. The data collected is sent back to the ECM via the wiring harness, allowing the ECM to make real-time adjustments to ensure optimal engine performance and efficiency.

Safety and Reliability

By providing a structured and organized pathway for electrical signals and power, the ECM Wiring Harness enhances the safety and reliability of the engine system. It reduces the risk of electrical shorts, ensures consistent signal integrity, and supports the overall durability of the engine’s electrical components.

Conclusion

The 3681451 Electronic Control Module Wiring Harness is a foundational component in modern engine systems, ensuring seamless communication, efficient power distribution, and reliable operation of electrical accessories. Proper installation, maintenance, and understanding of its role are crucial for the optimal performance and longevity of commercial trucks and engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.