FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

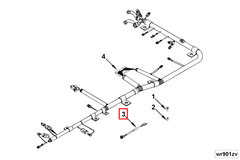

The 3942879 Electronic Control Module Wiring Harness, manufactured by Cummins, is a vital component in the operation of commercial trucks. This wiring harness facilitates the communication between the Electronic Control Module (ECM) and various electrical systems within the truck, ensuring efficient and reliable performance.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a network of wires and connectors that link the ECM to other electrical components in a truck. It consists of insulated wires, connectors, and terminals. The harness transmits signals and power between the ECM and components such as sensors, actuators, and other control units, enabling the ECM to monitor and regulate the truck’s operations 1.

Role of the 3942879 Electronic Control Module Wiring Harness in Truck Operation

The 3942879 Wiring Harness plays a significant role in the overall operation of a commercial truck. It establishes a communication pathway between the ECM and various truck systems, including the engine, transmission, brakes, and emissions control systems. This allows the ECM to receive data from sensors, process it, and send commands to actuators, ensuring the truck operates smoothly and efficiently 2.

Key Features of the 3942879 Wiring Harness

The 3942879 Wiring Harness is designed with several key features that enhance its performance and durability. It is constructed using high-quality materials that are resistant to wear, corrosion, and environmental factors. The harness is engineered to meet stringent industry standards, ensuring reliable operation in demanding conditions. Additionally, it features a robust design that protects the wires from physical damage and provides easy access for maintenance and repairs 3.

Benefits of Using the 3942879 Wiring Harness

Using the 3942879 Wiring Harness offers several benefits. It improves the reliability of the truck’s electrical system by providing a secure and efficient connection between the ECM and other components. The harness is designed for ease of installation, reducing downtime during maintenance. Its durable construction ensures long-term performance, minimizing the need for frequent replacements. Furthermore, the harness contributes to the overall efficiency of the truck by enabling precise control and monitoring of various systems 4.

Installation Considerations

Proper installation of the 3942879 Wiring Harness is crucial for ensuring optimal performance and longevity. It is important to follow the manufacturer’s guidelines and ensure compatibility with the specific truck model and system. Careful routing of the wires and secure connection of all terminals are necessary to prevent issues such as short circuits or signal interference. Professional installation is recommended to avoid potential problems and ensure the harness functions as intended 1.

Maintenance and Troubleshooting

Regular maintenance of the 3942879 Wiring Harness is important to ensure continued reliable operation. Inspecting the harness for signs of wear, corrosion, or damage and addressing any issues promptly can prevent more significant problems. Common troubleshooting tips include checking for loose connections, ensuring proper wire routing, and verifying that all terminals are securely attached. Following a maintenance schedule and addressing any abnormalities can help maintain the harness’s performance 2.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer with a long-standing reputation in the automotive industry. The company is known for its commitment to quality, innovation, and customer satisfaction. Cummins has a history of developing reliable and high-performance components for commercial vehicles, including engines, powertrains, and electrical systems. Their dedication to advancing technology and meeting industry standards has established them as a trusted provider of automotive solutions 3.

Cummins Electronic Control Module Wiring Harness 3942879

The Electronic Control Module (ECM) Wiring Harness 3942879 by Cummins is a critical component designed to ensure seamless communication and power distribution between the ECM and various engine control units. This wiring harness is specifically engineered to fit seamlessly with several Cummins engine models, ensuring compatibility and reliability.

Compatibility with Cummins Engines

ISB CM550

The ECM Wiring Harness 3942879 is meticulously designed to integrate with the ISB CM550 engine. This model is known for its robust performance and efficiency, making it a popular choice in various applications. The wiring harness ensures that all electrical signals are transmitted accurately, maintaining the engine’s optimal performance.

QSB5.9 44 CM550

Similarly, the ECM Wiring Harness 3942879 is also compatible with the QSB5.9 44 CM550 engine. This engine variant is renowned for its versatility and reliability, often used in a range of industrial and commercial applications. The wiring harness is engineered to handle the specific electrical demands of this engine, ensuring consistent and reliable operation.

Key Features

- Precision Engineering: The wiring harness is designed to fit perfectly with the specified engine models, minimizing the risk of electrical faults.

- Durability: Constructed from high-quality materials, the harness is built to withstand the rigors of continuous use in demanding environments.

- Ease of Installation: The harness is designed for straightforward installation, reducing downtime and maintenance costs.

By ensuring a reliable connection between the ECM and other engine components, the ECM Wiring Harness 3942879 plays a crucial role in maintaining the performance and longevity of Cummins engines 4.

Role of Part 3942879 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified as part 3942879, serves as the vital nervous system within modern engine systems, facilitating seamless communication and power distribution among various components. This harness is meticulously designed to interface with the ECM, ensuring that all electronic signals are accurately transmitted and received 1.

Integration with Accessories

The ECM Wiring Harness is integral to the operation of engine accessories. It provides the necessary electrical connections that allow accessories such as the alternator, fuel pump, and ignition system to function correctly. By supplying power and receiving feedback signals, the harness ensures that these accessories operate in harmony with the engine’s requirements, optimizing performance and efficiency 2.

Wiring Coordination

In terms of wiring, the ECM Wiring Harness acts as the central conduit for all electrical signals within the engine system. It connects the ECM to sensors, actuators, and other control units, enabling real-time data exchange. This coordination is essential for maintaining engine health, as it allows the ECM to make instantaneous adjustments based on sensor inputs, such as temperature, pressure, and airflow.

The harness also plays a key role in managing the power distribution to various engine components. It ensures that each component receives the correct voltage and current, preventing issues such as overheating or malfunction. Additionally, the harness incorporates protective measures, such as fuses and relays, to safeguard the electrical system from potential faults 3.

Conclusion

In summary, the ECM Wiring Harness (part 3942879) is a fundamental component in the engine system, ensuring that all electronic interactions are smooth, reliable, and efficient. Its role in connecting and powering accessories and managing wiring coordination is indispensable for the overall performance and reliability of the engine 4.

-

Diesel Mechanics, First Edition, Frank Sander, Global Media, 2007

↩ ↩ ↩ -

Modern Diesel Technology Preventive Maintenance and Inspection, John Dixon, Delmar Cengage Learning, 2010

↩ ↩ ↩ -

Alternative Powertrains and Extensions to the Conventional Powertrain, Michael Hilgers, Springer Nature, 2023

↩ ↩ ↩ -

Cars Encyclopedia, Clive Gifford, DK Publishing, 2014

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.