FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

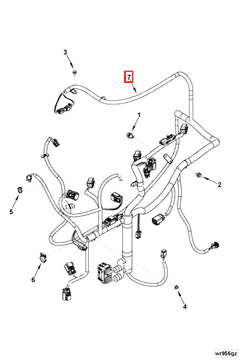

The Electronic Control Module Wiring Harness (Part #3963718) by Cummins is a vital component in the electronics of heavy-duty trucks. Manufactured by Cummins Inc., a leader in the automotive industry, this wiring harness is designed to facilitate the communication and operation of various electronic components within the vehicle.

Basic Concepts

Electronic Control Module Wiring Harnesses serve as the backbone of a vehicle’s electronic system. They enable communication between the Electronic Control Module (ECM) and other electronic components, ensuring that signals and data are transmitted efficiently. This system plays a role in the overall functionality and performance of the vehicle’s electronics 1.

Purpose and Functionality

This Cummins part is integral to the operation of a truck. It connects various electronic components, allowing them to communicate and work together seamlessly. This harness plays a role in ensuring that the ECM receives accurate data from sensors and that commands from the ECM are effectively executed by the truck’s systems 2.

Key Features

The 3963718 is characterized by its robust design and high-quality construction materials. It is engineered to withstand the demanding conditions of heavy-duty truck environments. Features such as corrosion-resistant materials and durable connectors enhance its performance and reliability, ensuring long-term operation under various conditions 3.

Benefits

The use of this part offers several advantages. It contributes to improved engine performance by ensuring precise communication between the ECM and other components. Additionally, it plays a role in enhancing fuel efficiency and increasing the reliability of the truck’s electronic systems, leading to more efficient and dependable vehicle operation.

Installation and Compatibility

Installing the 3963718 requires attention to specific guidelines to ensure proper integration with the truck’s electronic system. Compatibility with different truck models and engine types is a consideration during installation, highlighting the importance of following manufacturer recommendations for optimal performance.

Troubleshooting and Maintenance

Regular maintenance and prompt troubleshooting are key to ensuring the longevity and performance of the 3963718. Common issues may include connectivity problems or damage to the harness. Addressing these issues promptly and performing routine checks can help maintain the harness’s efficiency and reliability.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, known for its wide range of products and commitment to quality. With a rich history and a strong reputation, Cummins continues to be a trusted name in the production of automotive components, including the 3963718.

Role of the Electronic Control Module Wiring Harness (Part 3963718) in Engine Systems

The Electronic Control Module Wiring Harness (Part 3963718) serves as the vital connective tissue within an engine system, facilitating seamless communication and power distribution among various components. This harness is integral to the operation of the engine, ensuring that all electronic systems function in harmony.

Integration with Key Components

-

Electronic Control Module (ECM): The wiring harness directly interfaces with the ECM, which acts as the brain of the engine system. It transmits data and power between the ECM and other electronic components, allowing the ECM to monitor and adjust engine performance in real-time.

-

Sensors: Various sensors, such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensor, and Manifold Absolute Pressure (MAP) sensor, rely on the wiring harness to send critical data to the ECM. This data helps the ECM make informed decisions about fuel injection, ignition timing, and other parameters.

-

Actuators: Components like the fuel injectors, idle air control valve, and throttle position sensor receive commands from the ECM via the wiring harness. These actuators adjust engine operations based on the ECM’s instructions, ensuring optimal performance and efficiency.

-

Ignition System: The harness connects the ECM to the ignition coils and spark plugs. It ensures that the ignition system fires at the precise moments determined by the ECM, contributing to smooth and efficient combustion.

-

Emission Control Systems: Components such as the Exhaust Gas Recirculation (EGR) valve and the Evaporative Emission Control (EVAP) system are also linked through the wiring harness. This connection allows the ECM to manage emissions effectively, ensuring compliance with environmental regulations.

-

Battery and Power Supply: The wiring harness includes connections to the vehicle’s battery and other power sources. It ensures that all electronic components receive the necessary voltage to operate correctly.

Enhanced System Reliability

By providing a robust and organized pathway for electrical signals and power, the Electronic Control Module Wiring Harness (Part 3963718) enhances the reliability and performance of the engine system. It minimizes the risk of electrical faults and ensures that all components work together seamlessly, leading to improved engine efficiency and durability.

Conclusion

The 3963718 Electronic Control Module Wiring Harness is a critical component in the operation of heavy-duty trucks. Its robust design, integration with key engine components, and role in enhancing system reliability make it an essential part of the vehicle’s electronic system. Proper installation, maintenance, and troubleshooting are vital to ensuring its long-term performance and efficiency.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.