FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

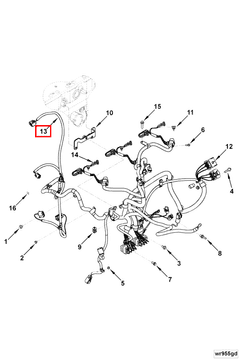

The Electronic Control Module Wiring Harness (Part #3965224) by Cummins is a vital component in the operation of commercial trucks. This wiring harness facilitates the connection between the Electronic Control Module (ECM) and various sensors and actuators throughout the vehicle. Its role is significant in ensuring the efficient and reliable operation of the truck’s electronic systems.

Basic Concepts

Electronic Control Module Wiring Harnesses are integral to a vehicle’s electronic system. They serve as the communication network that allows the ECM to interact with sensors and actuators. This interaction enables the ECM to monitor and control various functions of the truck, such as engine performance, transmission operations, and emissions control. Understanding the function of these wiring harnesses is fundamental to grasping how modern trucks operate 1.

Purpose and Role

This Cummins part is designed to connect the ECM to a wide array of sensors and actuators within the truck. This connection allows the ECM to receive data from sensors regarding the truck’s operating conditions and to send commands to actuators to adjust operations as needed. The harness plays a role in facilitating real-time data exchange, which is crucial for the ECM to make informed decisions and adjustments to optimize truck performance and efficiency 2.

Key Features

The 3965224 Wiring Harness is characterized by its robust design and the high-quality materials used in its construction. It is engineered to withstand the harsh conditions typically encountered in commercial trucking, including exposure to vibrations, temperature extremes, and moisture. The harness incorporates advanced insulation and shielding to protect against electrical interference and ensure signal integrity. Additionally, its design allows for easy integration into the truck’s existing electronic system, minimizing installation complexity 3.

Benefits

The implementation of the 3965224 Wiring Harness offers several advantages. It contributes to improved reliability by ensuring stable and consistent communication between the ECM and other components. This reliability is crucial for maintaining optimal truck performance under varying operating conditions. Furthermore, the harness supports enhanced performance by enabling precise control and monitoring of the truck’s systems. Potential cost savings can also be realized through efficient operation and reduced maintenance requirements.

Installation and Integration

Proper installation and integration of this part are critical for ensuring its effective operation. Installation should follow manufacturer guidelines to ensure compatibility with the truck’s electronic system and to avoid any potential issues. Specific considerations may include ensuring proper grounding, securing the harness to prevent damage from vibrations, and protecting it from environmental factors.

Troubleshooting and Maintenance

Regular maintenance and prompt troubleshooting of the Electronic Control Module Wiring Harness are important for its longevity and optimal performance. Common issues may include loose connections, damaged wires, or corrosion. Maintenance practices should include periodic inspections for signs of wear or damage, ensuring connections are secure, and protecting the harness from environmental factors. Troubleshooting should involve systematic checks to identify and address any issues affecting the harness’s performance.

Safety Considerations

Safety is a paramount concern when installing, maintaining, and operating the 3965224 Wiring Harness. Potential hazards include electrical shocks, fires due to short circuits, and system malfunctions leading to unsafe operating conditions. Mitigation strategies include following proper installation procedures, using appropriate personal protective equipment during maintenance, and adhering to safety guidelines when working with electrical systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and a strong reputation within the commercial truck industry, Cummins is known for its high-quality products and commitment to customer satisfaction. The company’s extensive product offerings and technological advancements have made it a preferred choice for commercial truck operators worldwide.

Role of Part 3965224 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified by part number 3965224, is integral to the operation of modern engine systems. This harness serves as the vital link between the ECM and various engine components, facilitating the transmission of electrical signals that are essential for engine management and performance.

Integration with Engine Control Wiring

The ECM Wiring Harness is meticulously designed to interface with the engine control wiring. This integration allows for the seamless communication between the ECM and the engine’s electronic components. The harness routes signals from the ECM to actuators such as fuel injectors, ignition coils, and variable valve timing solenoids. Conversely, it also transmits feedback from sensors like the mass airflow sensor, oxygen sensors, and throttle position sensor back to the ECM. This bidirectional flow of data enables the ECM to make real-time adjustments to engine parameters, optimizing performance, fuel efficiency, and emissions control.

Functionality within the Harness

Within the harness, each wire is assigned a specific function, corresponding to a particular sensor or actuator. For instance, power and ground wires provide the necessary electrical supply, while signal wires carry data to and from the ECM. The harness also incorporates shielding to protect against electromagnetic interference, ensuring signal integrity. Additionally, the harness is equipped with connectors that mate with the ECM and various engine components, allowing for easy installation and maintenance.

Role in Engine Systems

In engine systems, the ECM Wiring Harness plays a pivotal role in several key areas:

- Fuel Management: It connects the ECM to fuel injectors, enabling precise control over fuel delivery based on engine load, speed, and other operating conditions.

- Ignition Control: The harness links the ECM to ignition coils, allowing for optimized spark timing that enhances combustion efficiency and power output.

- Emissions Control: By interfacing with oxygen sensors and other emissions-related components, the harness helps the ECM monitor and adjust engine operations to meet emissions standards.

- Engine Monitoring: It facilitates the transmission of data from various sensors to the ECM, allowing for continuous monitoring of engine health and performance.

Conclusion

In summary, the ECM Wiring Harness (part 3965224) is a fundamental component in modern engine systems, ensuring efficient and reliable communication between the ECM and engine components. Its proper functioning is essential for the optimal performance, efficiency, and compliance of the engine with regulatory standards.

-

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality (Elsevier, 2021).

↩ -

Saiful Bari, Diesel Engine Combustion, Emissions and Condition Monitoring (InTech, 2013).

↩ -

G.K. Awari, V.S. Kumbhar, and R.B. Tirpude, Automotive Systems Principles and Practice (CRC Press, 2011).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.