FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

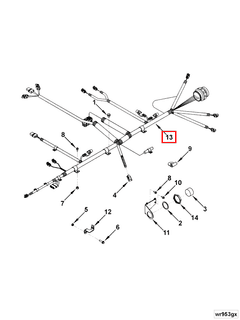

Introduction to Electronic Control Module Wiring Harnesses

An electronic control module (ECM) wiring harness is a critical component in modern commercial trucks. It serves as the conduit for electrical signals between the ECM and various sensors, actuators, and other electronic components within the engine. This harness ensures that the ECM can effectively communicate with other parts of the engine management system, enabling precise control over engine performance, emissions, and efficiency 1.

Purpose of the Cummins 3965704 Electronic Control Module Wiring Harness

The Cummins 3965704 electronic control module wiring harness plays a pivotal role in the operation of a truck’s engine. It is specifically designed to facilitate seamless communication between the ECM and other electronic components. This harness is crucial for:

- Signal Transmission: Ensuring that electrical signals are transmitted accurately and without interference.

- Power Distribution: Providing a reliable power supply to the ECM and connected components.

- Protection: Shielding the wiring from physical damage, moisture, and other environmental factors that could compromise its functionality 2.

How the Cummins 3965704 Electronic Control Module Wiring Harness Works

The Cummins 3965704 electronic control module wiring harness operates by connecting the ECM to various sensors and actuators throughout the engine. Here’s a step-by-step overview of its operation:

-

Sensor Data Collection: Sensors monitor various parameters such as engine temperature, air intake, and exhaust emissions. These sensors send data to the ECM.

-

Data Processing: The ECM processes the incoming data to determine the optimal engine settings for performance and efficiency.

-

Signal Transmission: The ECM sends control signals to actuators and other components, such as fuel injectors, ignition coils, and the turbocharger, to adjust engine operation accordingly.

-

Feedback Loop: The sensors continuously provide feedback to the ECM, creating a closed-loop system that allows for real-time adjustments 3.

Troubleshooting and Maintenance of the Cummins 3965704 Electronic Control Module Wiring Harness

Proper maintenance and troubleshooting of the Cummins 3965704 electronic control module wiring harness are essential for ensuring the longevity and reliability of the engine management system. Here are some tips:

-

Regular Inspections: Periodically inspect the wiring harness for signs of wear, such as frayed wires, loose connections, or corrosion. Address any issues promptly to prevent potential failures.

-

Cleaning: Keep the wiring harness clean and free from dirt and debris. Use a soft brush or compressed air to remove any buildup that could interfere with signal transmission.

-

Secure Connections: Ensure that all connections are secure and properly seated. Loose connections can lead to intermittent signal loss and performance issues.

-

Protective Measures: Use protective covers or conduits to shield the wiring harness from physical damage and environmental elements. This is particularly important in harsh operating conditions.

-

Professional Diagnostics: If you encounter issues with the engine management system, consult a professional technician who can use diagnostic tools to identify and resolve problems with the wiring harness 4.

Compatibility with ISL CM554 and QSL9 CM554 Engines

The ECM Wiring Harness 3965704 is specifically engineered to fit the ISL CM554 and QSL9 CM554 engines. These engines are part of Cummins’ lineup and are known for their robust performance and reliability in various industrial and commercial applications.

ISL CM554 Engines:

- The ISL CM554 engines are part of Cummins’ ISL series, which is designed for heavy-duty applications. This engine model is known for its high power output and efficiency. The ECM Wiring Harness 3965704 ensures that the ECM can effectively manage engine operations by providing accurate and timely data from the engine’s sensors.

QSL9 CM554 Engines:

- The QSL9 CM554 engines are another variant within Cummins’ lineup, offering a balance of power and fuel efficiency. The ECM Wiring Harness 3965704 is crucial for these engines as it facilitates the transmission of essential data between the ECM and other engine components, ensuring optimal performance and reliability.

Importance of the ECM Wiring Harness

The ECM Wiring Harness 3965704 plays a pivotal role in maintaining the integrity of the engine’s electronic control system. It ensures that the ECM can accurately monitor and control various engine parameters, such as fuel injection timing, air intake, and exhaust emissions. This harness is designed to withstand the harsh conditions of engine operation, providing a durable and reliable connection between the ECM and other critical components.

Installation and Maintenance

Proper installation of the ECM Wiring Harness 3965704 is essential to avoid any potential issues with engine performance. Technicians should follow Cummins’ recommended procedures for installation to ensure that all connections are secure and correctly routed. Regular maintenance checks should be performed to inspect for any signs of wear or damage, which could affect the harness’s performance.

Conclusion

The Cummins 3965704 electronic control module wiring harness is an integral part of the engine management system in commercial trucks. Understanding its purpose, operation, and maintenance is crucial for ensuring optimal engine performance and reliability. By following best practices for inspection and care, fleet operators and mechanics can extend the life of this essential component and maintain the efficiency of their trucks.

References

-

Hilgers, Michael. Entire Vehicle: Second Edition. Springer Nature, 2023.

↩ -

Zhao, Hua. Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press, 2010.

↩ -

Majewski, Addy, and Hannu Jaskelainen. Diesel Emissions and Their Control: Second Edition. SAE International, 2023.

↩ -

Cummins Inc. Service Manual (5504589). L9 CM2670 L128B, Cummins Inc.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.