FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

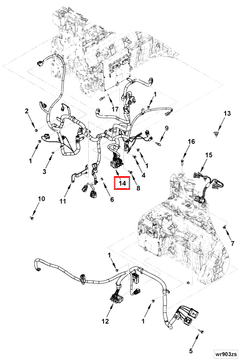

The Electronic Control Module Wiring Harness (Part #3969688) by Cummins is a vital component in the operation of heavy-duty trucks. This wiring harness is designed to facilitate the communication between the Electronic Control Module (ECM) and various other systems within the truck. Manufactured by Cummins, a reputable name in the automotive and heavy-duty truck industry, this component is engineered to meet the demanding requirements of commercial vehicle applications 1.

Basic Concepts

The Electronic Control Module (ECM) serves as the brain of the truck, managing and regulating various operations such as engine performance, transmission, and emissions control. The wiring harness plays a role in connecting the ECM to these different systems, ensuring seamless communication and operation. It consists of a network of wires, connectors, and terminals that transmit electrical signals and power between the ECM and other components 2.

Purpose and Functionality

This Cummins part is designed to support the operation of a truck by enabling the ECM to communicate with and control various systems. This includes the engine, transmission, braking system, and other critical components. By providing a reliable pathway for electrical signals, the wiring harness ensures that the ECM can effectively monitor and adjust the performance of these systems in real-time.

Key Features

The 3969688 Wiring Harness is characterized by its robust design and high-quality materials. It is constructed using durable materials that can withstand the harsh conditions often encountered in heavy-duty truck applications. The harness features precise wiring and secure connections, which contribute to its reliability and performance. Additionally, it is designed with flexibility in mind, allowing for easy installation and integration within the truck’s electrical system.

Benefits

Utilizing the 3969688 Wiring Harness offers several advantages. It enhances the reliability of the truck’s electrical system by providing a secure and efficient pathway for electrical signals. This can lead to improved overall performance and potentially reduce the likelihood of electrical failures. Moreover, the durability of the harness can contribute to cost savings over time by minimizing the need for frequent repairs or replacements 3.

Installation and Integration

Proper installation of this part is crucial for ensuring its effectiveness and the overall performance of the truck. It should be carefully routed and secured within the truck’s electrical system to avoid damage and ensure optimal functionality. Compatibility with other components should be verified to ensure seamless integration. Following manufacturer guidelines during installation can help prevent issues and ensure the harness operates as intended.

Troubleshooting and Maintenance

Common issues with the 3969688 Wiring Harness may include loose connections, damaged wires, or corrosion at the terminals. Regular inspection and maintenance can help identify and address these issues before they lead to more significant problems. Cleaning terminals, securing connections, and protecting the harness from physical damage are effective maintenance practices that can prolong its lifespan and ensure optimal performance.

Safety Considerations

When working with the 3969688 Wiring Harness, it is important to follow safety guidelines to prevent electrical hazards. This includes ensuring the truck’s battery is disconnected before beginning any work on the electrical system. Using appropriate tools and personal protective equipment can also help safeguard against injury. Adhering to these precautions during installation, maintenance, and troubleshooting is vital for ensuring a safe working environment.

Technological Advancements

The 3969688 Wiring Harness incorporates several technological innovations that contribute to improved truck performance and efficiency. These may include advanced materials for enhanced durability, precise wiring for reliable signal transmission, and secure connections to prevent electrical issues. These advancements play a role in the overall efficiency and reliability of the truck’s electrical system.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance components, Cummins has earned a reputation for excellence. The company’s dedication to advancing technology and maintaining stringent quality standards ensures that its products, like the 3969688 Wiring Harness, meet the demanding needs of commercial vehicle applications.

Understanding the Role of the Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified by part number 3969688, is an integral component in the orchestration of various engine systems. This harness facilitates the seamless communication and power distribution between the ECM and other engine components, ensuring optimal performance and efficiency.

Integration with Engine Control Wiring

At the heart of the engine’s electronic system, the ECM Wiring Harness connects the ECM to the engine control wiring. This connection allows the ECM to receive data from sensors and send commands to actuators, thereby regulating engine operations such as fuel injection, ignition timing, and emissions control. The harness acts as the nervous system of the engine, transmitting vital information that enables the ECM to make real-time adjustments for peak performance.

Role in Air Heater Starting Systems

In systems equipped with air heater starting aids, the ECM Wiring Harness plays a significant role. It provides the necessary electrical connections for the air heater to operate under cold start conditions. The harness ensures that the ECM can monitor the air heater’s status and control its activation, which is essential for facilitating smooth engine starts in low-temperature environments. This integration is particularly important for engines operating in regions with extreme cold, where traditional starting methods may be insufficient.

Coordination with Auxiliary Systems

Beyond the primary engine control functions, the ECM Wiring Harness also interfaces with auxiliary systems such as the Air Intake System and Exhaust Gas Recirculation (EGR). By providing the electrical pathways for these systems, the harness enables the ECM to optimize air-fuel mixture and reduce emissions, contributing to both performance and environmental compliance.

Ensuring System Integrity

The ECM Wiring Harness is designed to withstand the harsh conditions within the engine compartment, including heat, vibration, and exposure to chemicals. Its robust construction ensures reliable operation and longevity, which is essential for maintaining the integrity of the engine’s electronic systems.

Conclusion

In summary, the ECM Wiring Harness (part 3969688) is a fundamental component that enables the ECM to effectively manage and control various engine systems. Its role in facilitating communication and power distribution is essential for the efficient and reliable operation of modern engines.

-

Hilgers, Michael. Vocational Vehicles and Applications. Springer Nature, 2023.

↩ -

Brown Jr, Andrew. Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences, 2010.

↩ -

Pulkrabek, Willard W. Engineering Fundamentals of the Internal Combustion Engine. Pearson Education, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.