3970310

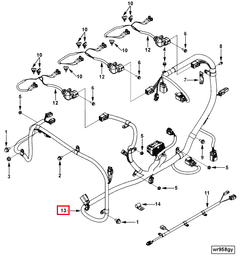

Electronic Control Module Wiring Harness

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3970310 Electronic Control Module Wiring Harness by Cummins is a vital component in the electrical system of commercial trucks. Its purpose is to facilitate the communication and power distribution between the Electronic Control Module (ECM) and various sensors, actuators, and other electronic components within the truck. This harness ensures that the ECM can effectively monitor and control the truck’s operations, contributing to overall performance, efficiency, and reliability.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a network of wires and connectors designed to link the ECM with other electronic components in the truck. It consists of multiple wires, each serving a specific function, bundled together in a protective sheath. The harness allows for the transmission of electrical signals and power, enabling the ECM to receive data from sensors and send commands to actuators. This system is integral to the truck’s electrical architecture, ensuring seamless operation of various subsystems.

Role of the 3970310 Wiring Harness in Truck Operation

The 3970310 Wiring Harness plays a significant role in the operation of a truck by providing the necessary connections for the ECM to interact with other systems. It allows the ECM to receive input from sensors such as temperature, pressure, and position sensors, and to send output signals to actuators that control functions like fuel injection, ignition timing, and emissions systems. This harness ensures that the ECM can effectively manage the truck’s performance, fuel efficiency, and emissions compliance.

Key Features of the 3970310 Wiring Harness

The 3970310 Wiring Harness is designed with several key features to enhance its functionality and durability. These include high-quality materials that resist wear and environmental factors, precise engineering to ensure reliable connections, and a robust design that can withstand the vibrations and harsh conditions typical in commercial truck operations. Additionally, the harness is engineered for easy integration with the truck’s existing electrical system, facilitating straightforward installation and maintenance.

Benefits of Using the 3970310 Wiring Harness

Using the 3970310 Wiring Harness offers several benefits. It enhances the reliability of the truck’s electrical system by providing secure and consistent connections. This leads to improved performance and efficiency, as the ECM can accurately monitor and control the truck’s operations. Furthermore, the harness contributes to the overall durability and longevity of the truck’s electrical components, reducing the likelihood of failures and the need for frequent repairs.

Installation and Integration

When installing the 3970310 Wiring Harness, it is important to follow manufacturer guidelines to ensure proper integration with the truck’s electrical system. This includes verifying compatibility with the truck’s make and model, ensuring all connections are secure and correctly routed, and testing the system to confirm functionality. Careful attention to these steps will help maintain the integrity of the electrical system and ensure optimal performance.

Troubleshooting Common Issues

Common issues with the 3970310 Wiring Harness may include loose connections, damaged wires, or faulty sensors. Troubleshooting these issues involves systematic diagnostic procedures, such as checking for continuity in the wires, inspecting connectors for corrosion or damage, and using diagnostic tools to identify faulty components. Addressing these issues promptly can prevent more significant problems and ensure the continued reliable operation of the truck.

Maintenance Tips

Regular maintenance of the 3970310 Wiring Harness is crucial for ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, cleaning connectors to prevent corrosion, and verifying that all connections remain secure. Additionally, protecting the harness from physical damage and environmental factors can help maintain its integrity over time.

Safety Considerations

When working with the 3970310 Wiring Harness, several safety considerations should be kept in mind. These include ensuring the truck’s battery is disconnected before beginning any work to prevent electrical shocks, using appropriate tools and personal protective equipment, and following all manufacturer guidelines for handling and installation. Adhering to these safety practices will help protect both the technician and the equipment.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable, high-performance products. The company’s commitment to innovation and quality ensures that its components, like the 3970310 Wiring Harness, meet the demanding requirements of modern commercial trucks.

Electronic Control Module Wiring Harness (Part 3970310) Compatibility with Cummins Engines

The Electronic Control Module (ECM) Wiring Harness (Part 3970310) manufactured by Cummins is designed to integrate seamlessly with a variety of Cummins engines. This wiring harness is crucial for the proper functioning of the ECM, ensuring that electrical signals are transmitted accurately and efficiently between the ECM and other engine components.

ISL9 CM2150 SN Engines

The ISL9 CM2150 SN engines are high-performance, heavy-duty engines that are often used in demanding applications such as construction equipment, mining machinery, and other industrial settings. The ECM Wiring Harness (Part 3970310) is specifically engineered to fit these engines, providing a reliable and robust connection that can withstand the rigors of these environments.

The harness is designed to connect the ECM to various sensors, actuators, and other electronic components, ensuring that the engine operates smoothly and efficiently. The harness is also designed to be easy to install and maintain, reducing downtime and increasing the overall reliability of the engine.

Grouping of Engines

When considering the compatibility of the ECM Wiring Harness (Part 3970310) with Cummins engines, it is important to note that this part is designed to fit a range of engines within the same family. For example, the ISL9 CM2150 SN engines are part of a larger family of Cummins engines that share similar design and functionality.

By grouping engines in this way, it becomes easier to ensure that the ECM Wiring Harness (Part 3970310) is compatible with a wide range of engines, providing a versatile and reliable solution for engine maintenance and repair.

Installation and Maintenance

The ECM Wiring Harness (Part 3970310) is designed to be easy to install and maintain, reducing the time and effort required for engine maintenance and repair. The harness is made from high-quality materials that are resistant to wear and tear, ensuring that it can withstand the rigors of engine operation.

When installing the ECM Wiring Harness (Part 3970310), it is important to follow the manufacturer’s instructions carefully, ensuring that all connections are made securely and correctly. Regular maintenance and inspection of the harness can help to identify any potential issues before they become serious problems, ensuring that the engine operates smoothly and efficiently.

Role of Part 3970310 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified by part number 3970310, serves as the vital connective tissue within engine systems, ensuring seamless communication and power distribution between the ECM and various engine components. This harness is engineered to interface with a multitude of engine subsystems, facilitating the ECM’s role in monitoring and controlling engine operations.

Integration with Engine Components

-

Sensors and Actuators: The ECM Wiring Harness connects an array of sensors—such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and Manifold Absolute Pressure (MAP) sensor—to the ECM. It also links actuators, including the fuel injectors, throttle body, and various solenoids, enabling the ECM to adjust engine parameters in real-time based on sensor inputs.

-

Power Supply: It provides a dedicated power supply to the ECM, ensuring stable operation. This includes connections to the battery and ignition system, allowing the ECM to receive the necessary voltage to function correctly.

-

Grounding: Proper grounding is essential for the ECM’s performance. The harness includes grounding wires that connect the ECM to the engine block or chassis, ensuring a stable reference voltage and reducing electrical noise.

-

Communication Networks: In modern engine systems, the ECM Wiring Harness also interfaces with onboard communication networks, such as the Controller Area Network (CAN) bus. This allows the ECM to share data with other control modules within the vehicle, enhancing overall vehicle performance and diagnostics.

-

Environmental Protection: The harness is designed with protective coatings and shielding to withstand the harsh environment under the hood, including exposure to heat, oil, and vibration. This ensures longevity and reliable performance of the ECM and connected components.

Conclusion

In summary, the ECM Wiring Harness (part 3970310) is a fundamental component in the engine system, responsible for the efficient and reliable operation of the ECM and its interactions with various engine components. Its design and functionality are tailored to support the complex demands of modern engine management systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.