FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

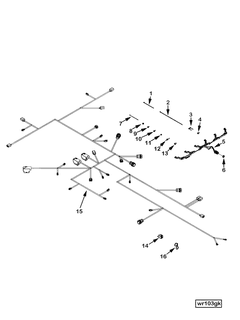

The 4333188 Electronic Control Module Wiring Harness is a component manufactured by Cummins, a well-established name in the commercial truck industry. This wiring harness is integral to the operation of commercial trucks, facilitating the communication between the Electronic Control Module (ECM) and various other systems within the vehicle.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a network of wires and connectors that link the ECM to other electronic components in a truck. It consists of multiple wires, connectors, and protective sheathing. The harness functions by transmitting signals and power between the ECM and other systems, ensuring that the truck operates efficiently and effectively 1.

Role of the 4333188 Wiring Harness in Truck Operation

The 4333188 Wiring Harness plays a specific role in the operation of a commercial truck. It serves as the communication pathway between the ECM and other electronic systems, such as the engine, transmission, and braking systems. This interaction allows the ECM to monitor and control various functions, optimizing the truck’s performance and ensuring smooth operation.

Key Features of the 4333188 Wiring Harness

The 4333188 Wiring Harness is designed with several key features that enhance its performance and durability. It is constructed using high-quality materials that are resistant to wear and environmental factors. The harness is also designed to be compact and flexible, allowing for easy installation and integration within the truck’s electrical system. Additionally, it features robust connectors that ensure secure and reliable connections.

Benefits of Using the 4333188 Wiring Harness

The 4333188 Wiring Harness offers several benefits. Its high-quality construction and design contribute to improved reliability and efficiency. The harness is also easier to install compared to other wiring harnesses, reducing downtime and maintenance costs. Furthermore, its durable materials and robust design ensure long-term performance and reduced need for replacements.

Installation Process

Installing the 4333188 Wiring Harness involves several steps. First, ensure that the truck’s electrical system is powered down to avoid any risk of electrical shock. Next, route the harness through the designated pathways within the truck, ensuring that it is securely fastened and protected from potential damage. Finally, connect the harness to the ECM and other electronic components, ensuring that all connections are secure and properly aligned.

Common Issues and Troubleshooting

Common issues with the 4333188 Wiring Harness may include loose connections, damaged wires, or faulty connectors. To troubleshoot these issues, begin by inspecting the harness for any visible signs of damage. If a problem is identified, it may be necessary to repair or replace the affected section of the harness. Regular inspections and maintenance can help prevent these issues from occurring 2.

Maintenance Tips

To ensure the longevity and optimal performance of the 4333188 Wiring Harness, regular maintenance is recommended. This includes inspecting the harness for any signs of wear or damage, ensuring that all connections are secure, and cleaning the harness to remove any dirt or debris. Additionally, protecting the harness from environmental factors, such as moisture and extreme temperatures, can help extend its lifespan.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable, and innovative products. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding needs of commercial truck operators.

Cummins Engine Compatibility with Part 4333188

The Electronic Control Module (ECM) Wiring Harness, part number 4333188, manufactured by Cummins, is designed to integrate seamlessly with a range of Cummins engines. This wiring harness is a critical component that ensures the proper electrical connection between the ECM and other engine control units, facilitating efficient engine operation and diagnostics.

QSX15 Engine Series

The QSX15 engine series, known for its robust performance and reliability, is compatible with the 4333188 ECM Wiring Harness. This harness is engineered to fit the specific electrical architecture of the QSX15, ensuring that all necessary signals are transmitted accurately and without interference. The harness is designed to withstand the demanding conditions of heavy-duty applications, providing a durable and reliable connection.

CM2250 Engine Series

Similarly, the CM2250 engine series benefits from the use of the 4333188 ECM Wiring Harness. This series is widely used in various industries due to its efficiency and power. The wiring harness is tailored to meet the electrical requirements of the CM2250, ensuring that the engine operates at peak performance. The harness is designed to be easy to install and maintain, reducing downtime and enhancing overall engine reliability.

Grouping by Application

In applications where both the QSX15 and CM2250 engines are used, the 4333188 ECM Wiring Harness can be utilized interchangeably. This flexibility allows for easier inventory management and reduces the need for multiple part numbers. The harness’s design ensures compatibility across these engine models, providing a standardized solution for complex electrical connections.

Installation Considerations

When installing the 4333188 ECM Wiring Harness, it is essential to follow the manufacturer’s guidelines to ensure a proper fit and function. The harness should be securely connected to the ECM and other relevant components, with all connections checked for tightness and integrity. Proper installation is crucial for maintaining the engine’s performance and preventing electrical issues.

Understanding the Role of Part 4333188 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified by part number 4333188, is an integral component in the orchestration of modern engine systems. This wiring harness serves as the vital conduit through which the ECM communicates with various engine components, ensuring seamless operation and optimal performance.

Communication with Engine Sensors

The ECM Wiring Harness facilitates the transfer of data between the ECM and a multitude of engine sensors. These sensors include the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, Manifold Absolute Pressure (MAP) sensor, and others. By relaying real-time data, the harness allows the ECM to make precise adjustments to fuel injection, ignition timing, and other critical parameters.

Integration with Actuators

In addition to sensors, the ECM Wiring Harness connects the ECM to various actuators within the engine system. This includes the fuel injectors, idle air control (IAC) valve, throttle position actuator, and variable valve timing (VVT) solenoids. Through this harness, the ECM can deliver commands to these actuators, dynamically adjusting engine performance based on driving conditions and sensor inputs.

Power Supply and Grounding

A fundamental role of the ECM Wiring Harness is to provide a reliable power supply to the ECM and ensure proper grounding. This involves connecting the harness to the vehicle’s battery and chassis ground points. Stable power and grounding are essential for the ECM to function correctly, process data, and issue commands to engine components.

Diagnostic and Communication Ports

Modern engine systems are equipped with On-Board Diagnostics (OBD) capabilities. The ECM Wiring Harness includes connections to diagnostic ports, allowing mechanics to interface with the ECM using diagnostic tools. This facilitates the retrieval of trouble codes, live data streaming, and performing various tests to diagnose engine issues.

Thermal Management

The ECM Wiring Harness also plays a part in thermal management by incorporating temperature sensors within its network. These sensors monitor the engine coolant temperature, intake air temperature, and other thermal parameters. The data collected helps the ECM make informed decisions regarding fuel delivery, ignition timing, and other parameters to prevent overheating and ensure efficient engine operation.

Emission Control Systems

In compliance with environmental regulations, the ECM Wiring Harness is designed to interface with emission control systems. This includes connections to the Evaporative Emission Control (EVAP) system, Exhaust Gas Recirculation (EGR) system, and Catalytic Converter. By monitoring and controlling these systems, the harness aids in minimizing harmful emissions and ensuring the engine meets regulatory standards.

Enhanced Driveability and Performance

Ultimately, the ECM Wiring Harness contributes to enhanced driveability and performance. By enabling precise communication between the ECM and engine components, the harness allows for real-time adjustments that optimize fuel efficiency, reduce emissions, and provide a smoother driving experience.

Conclusion

In summary, the ECM Wiring Harness (part 4333188) is a cornerstone of modern engine management systems, facilitating communication, control, and diagnostics across a wide array of engine components.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.