4981935

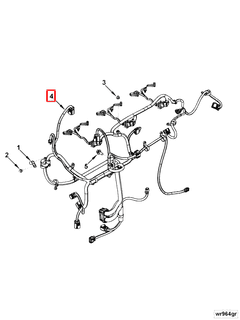

Electronic Control Module Wiring Harness

Cummins®

IN STOCK

8 are currently available

Ships within 1 business day

FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The 4981935 Electronic Control Module Wiring Harness is a component designed for use in commercial trucks. It serves to connect the Electronic Control Module (ECM) to various sensors, actuators, and other electronic components within the truck. This harness plays a significant role in facilitating communication and power distribution between the ECM and the truck’s electrical systems, thereby contributing to the overall functionality and performance of the vehicle 1.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a bundle of wires and connectors that link the ECM to other parts of the truck’s electrical system. It consists of insulated wires, connectors, and sometimes includes protective housings. The harness functions by transmitting signals and power from the ECM to various components, ensuring that the truck’s systems operate in harmony. It is integral to the truck’s electrical architecture, enabling the ECM to monitor and control engine performance, transmission functions, and other critical operations 2.

Role of the 4981935 Electronic Control Module Wiring Harness in Truck Operation

The 4981935 Wiring Harness is specifically engineered to interface with Cummins engines found in commercial trucks. It plays a role in the truck’s operation by providing a reliable connection pathway for data and power between the ECM and the engine’s electronic components. This includes sensors that monitor engine parameters, actuators that control various engine functions, and other electronic devices. The harness ensures that the ECM receives accurate data from sensors and can send appropriate commands to actuators, thus maintaining optimal engine performance and efficiency 3.

Key Features of the 4981935 Wiring Harness

The 4981935 Wiring Harness is characterized by several key features that enhance its functionality and reliability. These include robust construction to withstand the harsh environments typical of commercial trucking, a design that ensures easy integration with Cummins engines, and the use of high-quality materials to ensure durability and longevity. Additionally, the harness is engineered for ease of installation, featuring color-coded wires and connectors that simplify the connection process.

Benefits of Using the 4981935 Wiring Harness

Utilizing the 4981935 Wiring Harness offers several advantages. It contributes to improved reliability by ensuring secure and consistent connections between the ECM and the truck’s electronic components. This reliability translates into enhanced engine performance and efficiency. Furthermore, the harness’s design facilitates easier installation and maintenance, reducing downtime and operational costs for fleet managers.

Installation and Integration

When installing the 4981935 Wiring Harness, it is important to follow manufacturer guidelines to ensure proper integration into the truck’s electrical system. This involves identifying the correct routing paths for the harness to avoid interference with other components and ensuring that all connections are secure and correctly aligned. Careful attention to these details during installation helps maintain the integrity of the electrical system and ensures the harness functions as intended.

Troubleshooting Common Issues

Common issues with the 4981935 Wiring Harness may include loose connections, damaged wires, or faulty connectors. Troubleshooting these issues involves inspecting the harness for signs of wear or damage, ensuring all connections are tight and secure, and replacing any damaged components as necessary. Regular inspections and maintenance can help identify potential issues before they lead to more significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the 4981935 Wiring Harness, regular maintenance is recommended. This includes periodic inspections for signs of wear, corrosion, or damage, cleaning the harness and its connections to remove dirt and debris, and ensuring that all connections remain secure. Adhering to these maintenance practices can help prevent issues and extend the service life of the harness.

Safety Considerations

When working with the 4981935 Wiring Harness, it is important to observe safety precautions. This includes ensuring the truck’s electrical system is de-energized before beginning any work on the harness, using appropriate personal protective equipment, and following all manufacturer guidelines for handling, installation, and maintenance. These safety measures help protect both the technician and the equipment from potential hazards.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial transportation.

Compatibility with Cummins Engines

The Electronic Control Module Wiring Harness, identified by part number 4981935, is designed to interface with various Cummins engine models, facilitating the transmission of electrical signals between the engine control module (ECM) and other electronic components.

-

ISB CM2150 and ISB6.7 CM2250: These engines, known for their robust performance and reliability, are equipped with the 4981935 wiring harness to maintain precise control over engine operations. The harness ensures that the ECM can effectively communicate with sensors and actuators, optimizing fuel efficiency and power output.

-

QSB6.7 M CM2250: This engine model also benefits from the 4981935 wiring harness. The harness is designed to handle the specific electrical demands of the QSB6.7 M CM2250, ensuring that all electronic components are properly connected and functioning as intended.

Role of Part 4981935 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified by part number 4981935, is integral to the operation of modern engine systems. This harness serves as the vital link between the ECM and various engine components, facilitating the transmission of electrical signals that are essential for engine management and performance.

Integration with Engine Components

-

Sensors: The ECM Wiring Harness connects to a multitude of sensors such as the Mass Air Flow (MAF) sensor, Manifold Absolute Pressure (MAP) sensor, and Oxygen (O2) sensors. These sensors provide real-time data to the ECM about the engine’s operating conditions, allowing for precise control over fuel injection, ignition timing, and emissions.

-

Actuators: This harness also interfaces with actuators including the fuel injectors, throttle body, and various solenoids. By transmitting commands from the ECM, it ensures that these components operate in harmony with the engine’s requirements, optimizing performance and efficiency.

-

Ignition System: In ignition systems, the ECM Wiring Harness plays a key role in connecting the ECM to ignition coils and spark plugs. It ensures that the timing of spark delivery is accurately controlled, which is fundamental for combustion efficiency and engine power.

-

Emission Control Systems: The harness is connected to components of the emission control system, such as the Exhaust Gas Recirculation (EGR) valve and the catalytic converter. It enables the ECM to monitor and adjust these systems to meet environmental regulations while maintaining engine performance.

-

Battery and Power Supply: It also facilitates the connection between the ECM and the vehicle’s power supply, ensuring that the ECM receives a stable and sufficient voltage to operate effectively.

Conclusion

The 4981935 Electronic Control Module Wiring Harness is a critical component in the operation of Cummins engines, ensuring seamless electrical connectivity within the engine’s control system. Its robust design, compatibility with various Cummins engine models, and integral role in engine management and performance make it essential for maintaining optimal engine operation and efficiency.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.