FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

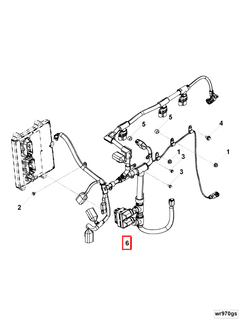

The 4997024 Wiring Harness for Electronic Control Module (ECM) produced by Cummins is a specialized component designed for the electrical systems of heavy-duty trucks. This Cummins part facilitates the connection between the ECM and various truck systems, ensuring efficient communication and power distribution.

Basic Concepts of Wiring Harness for Electronic Control Module

A wiring harness is an assembly of wires, connectors, and terminals that transmit electrical power and signals between different components of a vehicle. Within the context of an Electronic Control Module, the wiring harness plays a vital role in enabling the ECM to communicate with and control various truck systems. Typical components of a wiring harness include insulated wires, connectors, terminals, and protective housings 1.

Purpose of the 4997024 Wiring Harness for Electronic Control Module

This part is designed to support the operation of heavy-duty trucks by facilitating communication and power distribution between the ECM and other truck systems. It ensures that the ECM can effectively manage engine performance, transmission, and other critical functions by providing a reliable electrical connection.

Key Features

The 4997024 features several design elements and materials that enhance its performance and durability. These include high-quality insulated wires to prevent electrical interference, robust connectors for secure connections, and protective housings to shield the wires from physical damage and environmental factors. The harness is also designed with flexibility in mind, allowing for easier routing and installation within the truck’s chassis.

Benefits

Using the 4997024 in heavy-duty trucks offers several advantages. It provides improved reliability by ensuring consistent and secure electrical connections. The design of the harness also contributes to enhanced efficiency in power distribution and signal transmission. Additionally, the harness is engineered for ease of installation, reducing the time and effort required during setup.

Installation Process

Installing the 4997024 involves several steps to ensure a proper and secure connection. Begin by identifying the correct routing path for the harness within the truck’s chassis. Next, connect the harness to the ECM and other relevant components using the provided connectors. Ensure all connections are secure and insulated properly. Finally, test the harness to confirm that all systems are communicating effectively and that there are no electrical issues.

Troubleshooting Common Issues

Common problems with wiring harnesses can include loose connections, damaged wires, and electrical interference. For this model, specific issues might arise from improper installation or environmental damage. Troubleshooting tips include inspecting all connections for security, checking for signs of wear or damage on the wires, and ensuring that the harness is properly routed away from potential sources of interference.

Maintenance Tips

Regular maintenance of the 4997024 is important to ensure its continued reliable performance. This includes periodic inspection of the harness for any signs of wear, damage, or loose connections. Cleaning the harness and its components can also help prevent buildup that might interfere with electrical conductivity. If any damage is detected, it may be necessary to replace the affected section or the entire harness.

Safety Considerations

When working with the 4997024, it is important to observe several safety protocols. Ensure that the truck’s battery is disconnected before beginning any work to prevent electrical shocks. Use appropriate tools and protective equipment to handle the harness and its components safely. Additionally, follow all manufacturer guidelines for installation and maintenance to ensure the harness operates within safe parameters.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive industry, known for its high-quality engines and components. With a history of innovation and commitment to quality, Cummins has established a strong reputation for producing reliable and durable products. The company’s range of offerings includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications 2.

Compatibility with Cummins Engines

This wiring harness is compatible with several Cummins engine models, including:

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

The QSB6.7 CM850 (CM2850) and QSB7 CM2880 B117 engines are part of Cummins’ QSB series, known for their reliability and efficiency in various applications. The wiring harness for these engines is engineered to handle the specific electrical requirements of these models, ensuring optimal performance and durability.

The harness is designed to withstand the operational conditions these engines typically encounter, including variations in temperature, vibration, and exposure to elements. This ensures that the ECM can reliably receive data from sensors and send commands to actuators, maintaining engine efficiency and performance.

By integrating seamlessly with the ECM, the wiring harness supports critical functions such as fuel injection timing, air intake control, and exhaust gas recirculation. This integration is vital for maintaining the engine’s responsiveness and adherence to emission standards.

Role of Part 4997024 Wiring Harness for Electronic Control Module in Engine Systems

The Wiring Harness for Electronic Control Module (part 4997024) is an integral component in the orchestration of engine systems. It serves as the vital conduit that facilitates the seamless transmission of electrical signals between the Electronic Control Module (ECM) and various engine components.

This wiring harness is meticulously designed to interface with the ECM, which is the brain of the engine system, responsible for processing data from sensors and making real-time adjustments to engine performance. The harness connects to a multitude of components, including but not limited to, the fuel injectors, ignition coils, throttle position sensor, and oxygen sensors.

By providing a structured pathway for electrical signals, the harness ensures that the ECM receives accurate data from these components, allowing it to make precise adjustments to fuel delivery, ignition timing, and other critical parameters. Additionally, the harness is engineered to withstand the harsh environment within the engine compartment, ensuring reliable performance over the lifespan of the vehicle 3.

Conclusion

The 4997024 Wiring Harness for Electronic Control Module is a critical component for ensuring the efficient and reliable operation of heavy-duty trucks. Its design and features contribute to improved reliability, enhanced efficiency, and ease of installation. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.