5256262

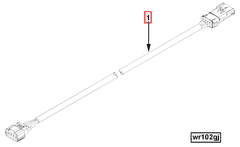

Electronic Control Module Wiring Harness

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 5256262 Electronic Control Module (ECM) Wiring Harness is a vital component in the electrical system of heavy-duty trucks. It serves as the conduit for communication between the ECM and various sensors and actuators throughout the vehicle. This wiring harness ensures that the ECM receives accurate data from sensors and can effectively control the truck’s systems, contributing to efficient and reliable operation 3.

Basic Concepts

Electronic Control Module Wiring Harnesses are integral to the vehicle’s electrical system. They facilitate the transmission of data and power between the ECM and other components. The ECM relies on this harness to gather information from sensors and to send signals to actuators that control various functions such as fuel injection, engine timing, and emissions systems. Understanding the function of these harnesses is fundamental to grasping how modern heavy-duty trucks operate 4.

Purpose and Role

The Cummins 5256262 ECM Wiring Harness is designed to enable seamless communication between the ECM and the truck’s sensors and actuators. This communication is crucial for the ECM to monitor and adjust the truck’s performance in real-time. By providing a reliable pathway for data and power, the wiring harness ensures that the ECM can make precise adjustments to optimize engine performance, fuel efficiency, and emissions control 1.

Key Features

The Cummins 5256262 ECM Wiring Harness is engineered with several key features that enhance its functionality and durability. Its design includes robust connectors and high-quality wires that are resistant to abrasion, heat, and corrosion. These features ensure that the harness can withstand the demanding conditions encountered in heavy-duty truck operations. Additionally, the harness is constructed to minimize electrical interference, which helps maintain signal integrity and ensures accurate data transmission 2.

Benefits

Utilizing the Cummins 5256262 ECM Wiring Harness offers several benefits. Its high-quality construction contributes to improved reliability, reducing the likelihood of electrical failures. The efficient design of the harness enhances the overall performance of the truck’s electrical system, leading to better fuel efficiency and reduced emissions. Moreover, the durability of the harness means that it requires less frequent maintenance, which can lower operational costs over time 3.

Troubleshooting and Maintenance

To ensure the optimal performance and longevity of the Cummins 5256262 ECM Wiring Harness, regular maintenance and troubleshooting practices are recommended. Inspecting the harness for signs of wear, corrosion, or damage can help identify potential issues before they lead to more significant problems. Cleaning the connectors and ensuring they are securely attached can prevent poor connections that may cause electrical issues. Additionally, following the manufacturer’s guidelines for maintenance can help maintain the harness’s integrity and performance 4.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a long-standing reputation for producing high-quality automotive components, particularly for heavy-duty trucks. Founded in 1919, Cummins has built a legacy of innovation and excellence in the automotive industry. The company’s expertise in engine technology and component manufacturing has made it a trusted name among fleet operators and maintenance professionals. Cummins’ commitment to quality and performance is evident in its wide range of products, including the Cummins 5256262 ECM Wiring Harness 1.

Cummins Engine Compatibility with Part 5256262

The Electronic Control Module (ECM) Wiring Harness part number 5256262, manufactured by Cummins, is designed to integrate seamlessly with a variety of Cummins engine models. This wiring harness is a crucial component for ensuring proper communication and power distribution between the ECM and various engine sensors and actuators. Below is a detailed breakdown of the engine compatibility for this specific part.

B6.7 Series Engines

- B6.7 CM2350

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

These engines benefit from the robust and reliable wiring harness, ensuring that all electrical signals are transmitted accurately and efficiently. The harness is engineered to withstand the rigors of heavy-duty applications, providing a stable connection that enhances engine performance and longevity.

ISB Series Engines

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

The ISB series engines, known for their versatility and power, are well-suited for the 5256262 wiring harness. This harness ensures that all electrical components are properly connected, facilitating optimal engine operation and diagnostics.

ISC Series Engines

- ISC8.3 CM2250

The ISC8.3 CM2250 engine is designed for applications requiring high torque and reliability. The wiring harness part 5256262 is tailored to meet these demands, providing a secure and efficient electrical connection.

ISF Series Engines

- ISF3.8 CM2350 F109

This engine model is often used in applications where fuel efficiency and performance are critical. The wiring harness ensures that all electrical components are properly interfaced, enhancing overall engine efficiency and reliability.

ISL Series Engines

- ISL9 CM2250

The ISL9 CM2250 engine is designed for heavy-duty applications. The 5256262 wiring harness is engineered to handle the demanding electrical requirements of this engine, ensuring stable and reliable performance.

ISX Series Engines

- ISX12 CM2350 X102

- ISX15 CM2350 X101

These high-performance engines are used in demanding applications such as construction and transportation. The wiring harness is designed to provide a robust and reliable connection, ensuring that all electrical signals are transmitted accurately and efficiently.

QSX Series Engines

- QSX11.9 CM2250 ECF

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

The QSX series engines are known for their power and efficiency. The 5256262 wiring harness is engineered to meet the stringent electrical requirements of these engines, ensuring optimal performance and reliability.

QSL Series Engines

- QSL9 CM2250

- QSL9 CM2350 L102

These engines are designed for heavy-duty applications. The wiring harness ensures that all electrical components are properly connected, facilitating optimal engine operation and diagnostics.

Other Models

- F3.8 CM2350 F120B

- F3.8 CM2350 F128C

These engines also benefit from the reliable and robust wiring harness, ensuring that all electrical signals are transmitted accurately and efficiently. The harness is engineered to withstand the rigors of heavy-duty applications, providing a stable connection that enhances engine performance and longevity.

This comprehensive compatibility ensures that the 5256262 wiring harness can be used across a wide range of Cummins engines, providing a reliable and efficient electrical connection 2.

Role of Part 5256262 Electronic Control Module Wiring Harness in Engine Systems

The Part 5256262 Electronic Control Module (ECM) Wiring Harness is an integral component in the orchestration of various engine systems. It serves as the primary conduit for electrical signals between the ECM and other critical engine components.

Integration with Engine Systems

-

Engine Control Wiring Harness: The ECM Wiring Harness interfaces directly with the Engine Control Wiring Harness. This connection allows the ECM to receive data from sensors such as the Mass Air Flow (MAF) sensor, Manifold Absolute Pressure (MAP) sensor, and Oxygen (O2) sensors. It also enables the ECM to send commands to actuators like the fuel injectors, ignition coils, and variable valve timing (VVT) solenoids.

-

Harness Extension: In scenarios where the standard length of the ECM Wiring Harness is insufficient, a Harness Extension can be employed. This extension maintains signal integrity while allowing for greater flexibility in the physical layout of engine components. It ensures that all connections remain secure and that data transmission between the ECM and other engine systems is unimpeded.

-

Electronic Control Module Wiring: The ECM Wiring itself is a network of wires that facilitates communication between the ECM and various subsystems within the engine. This includes the transmission control module, anti-lock braking system (ABS), and traction control system. The ECM Wiring Harness ensures that these subsystems operate in harmony, optimizing overall engine performance and efficiency.

Functional Synergy

The ECM Wiring Harness plays a pivotal role in the functional synergy of engine systems. By providing a reliable pathway for electrical signals, it enables the ECM to monitor and adjust engine operations in real-time. This results in enhanced fuel efficiency, reduced emissions, and improved drivability.

In summary, the Part 5256262 ECM Wiring Harness is a foundational element in the electrical architecture of modern engine systems, ensuring seamless communication and optimal performance across all connected components 3.

Conclusion

The Cummins 5256262 ECM Wiring Harness is a critical component in the electrical system of heavy-duty trucks, facilitating seamless communication between the ECM and various sensors and actuators. Its robust design, high-quality construction, and compatibility with a wide range of Cummins engines make it an essential part for ensuring optimal engine performance, fuel efficiency, and reliability. Regular maintenance and adherence to manufacturer guidelines are recommended to ensure the longevity and performance of this vital component 4.

-

Isermann, Rolf. Combustion Engine Diagnosis. Springer Vieweg, 2017.

↩ ↩ -

Bonnick, Allan. A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier, 2004.

↩ ↩ -

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ ↩ ↩ -

Garrett, TK, Newton, K, Steeds, W. The Motor Vehicle. Reed Educational and Professional Publishing Ltd, 2001.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.