5256263

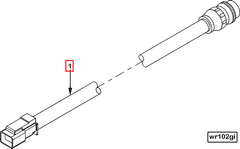

Electronic Control Module Wiring Harness

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Electronic Control Module Wiring Harness (Part #5256263) by Cummins is a specialized component designed for heavy-duty truck operations. This wiring harness serves as a vital link in the vehicle’s electronic system, facilitating communication between the Electronic Control Module (ECM) and various sensors and actuators. Its role is significant in ensuring the efficient and reliable operation of the truck’s engine and other critical systems.

Basic Concepts

Electronic Control Module Wiring Harnesses are integral to vehicle electronics and engine management systems. They consist of a network of wires and connectors that transmit signals and power between the ECM and the truck’s electronic components. This system allows for precise control over engine functions, monitoring of performance metrics, and the implementation of safety protocols 1.

Purpose and Function

The 5256263 Electronic Control Module Wiring Harness is designed to enable seamless communication between the ECM and the truck’s sensors and actuators. By providing a structured pathway for electrical signals, it ensures that the ECM receives accurate data from sensors and can send appropriate commands to actuators. This facilitates optimal engine performance, efficient fuel consumption, and effective management of emissions.

Key Features

The 5256263 Electronic Control Module Wiring Harness is characterized by its robust design and high-quality construction materials. It is engineered to withstand the harsh conditions typical of heavy-duty truck environments. Key features include durable connectors, corrosion-resistant materials, and a compact design that simplifies installation and maintenance. These attributes contribute to the harness’s performance and longevity.

Benefits

The implementation of the 5256263 Electronic Control Module Wiring Harness in a truck’s system offers several advantages. It contributes to improved engine performance by ensuring precise control over engine functions. Enhanced fuel efficiency is another benefit, as the harness allows for optimized fuel delivery based on real-time data from sensors. Additionally, the harness increases the reliability of truck operations by facilitating effective communication between the ECM and electronic components.

Installation and Compatibility

Installing the 5256263 Electronic Control Module Wiring Harness requires adherence to specific procedures to ensure proper integration with the truck’s electronic system. Compatibility with Cummins engines and other truck components is a key consideration, ensuring that the harness functions correctly within the vehicle’s architecture. Detailed instructions and guidelines are provided to facilitate a smooth installation process.

Troubleshooting and Maintenance

Regular maintenance and troubleshooting are vital for the optimal performance and longevity of the 5256263 Electronic Control Module Wiring Harness. Common issues may include loose connections, damaged wires, or faulty sensors. Diagnostic procedures and potential solutions are outlined to address these problems effectively. Routine maintenance tips are also provided to prevent issues and ensure the harness operates at peak efficiency.

Safety Considerations

When working with the 5256263 Electronic Control Module Wiring Harness, it is important to observe safety considerations to prevent electrical hazards. Proper handling procedures, including the use of insulated tools and adherence to electrical safety standards, are crucial. These precautions help protect both the technician and the vehicle’s electronic system from potential damage.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, known for its commitment to innovation, quality, and customer satisfaction. With a rich history of producing reliable and high-performance engines and components, Cummins has established a strong reputation for excellence. The company’s dedication to advancing technology and meeting the needs of its customers is evident in its diverse product offerings and continued growth in the market.

Cummins Electronic Control Module Wiring Harness (Part 5256263)

The Cummins Electronic Control Module (ECM) Wiring Harness, part number 5256263, is a critical component in the electrical architecture of various Cummins engines. This wiring harness is designed to ensure seamless communication and power distribution between the ECM and other engine control units, sensors, and actuators. Below is a detailed description of how this wiring harness fits with the specified Cummins engines.

B Series Engines

- B4.5 CM2350 B104

- B6.7 CM2350 B105

- B6.7 CM2350 B135B

The B series engines, including the B4.5 and B6.7 variants, utilize the ECM wiring harness to connect the ECM to various sensors and actuators. This harness ensures that the ECM can effectively monitor and control engine parameters such as fuel injection, air flow, and exhaust gas recirculation.

F Series Engines

- F3.8 CM2350 F107

- F3.8 CM2350 F109

- F3.8 CM2350 F120B

- F3.8 CM2350 F128C

The F series engines, particularly the F3.8 variants, rely on the ECM wiring harness to facilitate communication between the ECM and the engine’s sensors and actuators. This harness is crucial for maintaining optimal engine performance and efficiency by ensuring that the ECM can accurately read sensor data and control engine functions.

I Series Engines

- ISB4.5 CM2350 B104

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 CM2350 B135B

- ISC8.3 CM2250

- ISF3.8 CM2350 F109

- ISL9 CM2250

- ISV (Nissan)

The I series engines, including the ISB, ISC, and ISF variants, depend on the ECM wiring harness to connect the ECM to the engine’s sensors and actuators. This harness is essential for the proper functioning of the engine by ensuring that the ECM can accurately monitor and control various engine parameters.

QSB and QSL Series Engines

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSL9 CM2250

- QSL9 CM2350 L102

The QSB and QSL series engines use the ECM wiring harness to connect the ECM to the engine’s sensors and actuators. This harness is vital for maintaining engine performance and efficiency by ensuring that the ECM can accurately read sensor data and control engine functions.

QSF Series Engines

- QSF2.8 CM2880 F105

- QSF2.8 CM2880 F114

- QSF3.8 CM2350 F107

The QSF series engines, including the QSF2.8 and QSF3.8 variants, rely on the ECM wiring harness to connect the ECM to the engine’s sensors and actuators. This harness is essential for the proper functioning of the engine by ensuring that the ECM can accurately monitor and control various engine parameters.

QSX Series Engines

- QSX11.9 CM2250 ECF

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

The QSX series engines, including the QSX11.9, QSX15, and their variants, depend on the ECM wiring harness to connect the ECM to the engine’s sensors and actuators. This harness is crucial for maintaining optimal engine performance and efficiency by ensuring that the ECM can accurately read sensor data and control engine functions.

QSG Series Engine

- QSG12/X12 CM2350 G110

The QSG12/X12 engine utilizes the ECM wiring harness to connect the ECM to the engine’s sensors and actuators. This harness is essential for the proper functioning of the engine by ensuring that the ECM can accurately monitor and control various engine parameters.

ISX Series Engines

- ISX12 CM2350 X102

- ISX15 CM2350 X101

The ISX series engines, including the ISX12 and ISX15 variants, rely on the ECM wiring harness to connect the ECM to the engine’s sensors and actuators. This harness is crucial for maintaining engine performance and efficiency by ensuring that the ECM can accurately read sensor data and control engine functions.

Role of Part 5256263 Electronic Control Module Wiring Harness in Engine Systems

The Part 5256263 Electronic Control Module (ECM) Wiring Harness is an essential component that facilitates the communication and power distribution between the ECM and various engine system components. This harness is meticulously designed to ensure reliable and efficient operation of the engine by connecting multiple critical systems.

Integration with Engine Control Wiring Harness

The ECM Wiring Harness interfaces directly with the Engine Control Wiring Harness. This connection allows for the transmission of data and power to and from the ECM, enabling it to monitor and adjust engine performance in real-time. The Engine Control Wiring Harness typically includes connections to sensors such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and the Manifold Absolute Pressure (MAP) sensor. These sensors provide the ECM with vital information about the engine’s operating conditions, allowing for precise control over fuel injection, ignition timing, and other parameters 2.

Connection to Extension Harnesses

In many engine systems, the ECM Wiring Harness is extended using additional Extension Harnesses. These extensions are used to reach components that are located further away from the ECM, such as the fuel injectors, ignition coils, and various actuators. The Extension Harnesses ensure that all necessary connections are maintained without compromising the integrity of the signal or power transmission. This is particularly important in larger or more complex engine configurations where components are spread out over a greater distance.

Role in Overall System Functionality

The ECM Wiring Harness plays a significant role in the overall functionality of the engine system by providing a robust and reliable means of communication between the ECM and the various engine components. It ensures that all data transmitted is accurate and timely, which is essential for the ECM to make the correct adjustments to engine operation. Additionally, the harness supplies power to components that require it, ensuring that they function correctly.

Conclusion

In summary, the Part 5256263 ECM Wiring Harness is a fundamental component in the engine system, facilitating the necessary connections and communications that allow the ECM to effectively manage and optimize engine performance. Its robust design, compatibility with various Cummins engines, and role in ensuring efficient and reliable engine operation make it an indispensable part of heavy-duty truck systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.