FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

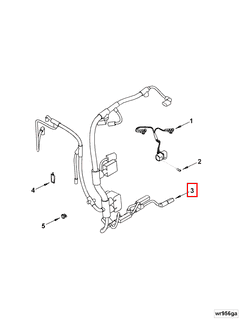

The Electronic Control Module Wiring Harness (Part #5262554) by Cummins is a vital component in the electronic systems of heavy-duty trucks. This wiring harness is designed to facilitate the communication and operation of various electronic components within the vehicle. Manufactured by Cummins, a renowned name in the automotive and heavy-duty truck industry, this part is engineered to meet the demanding requirements of modern truck electronics 1.

Basic Concepts

Electronic Control Module Wiring Harnesses serve as the backbone of a vehicle’s electronic system. They are responsible for transmitting signals and power between the Electronic Control Module (ECM) and other electronic components. This communication is crucial for the operation of the vehicle’s systems, including engine management, transmission control, and various sensor inputs. The wiring harness ensures that these components can interact seamlessly, allowing for optimized performance and efficiency 2.

Purpose and Functionality

The 5262554 Electronic Control Module Wiring Harness plays a significant role in the operation of a truck. It connects various electronic components, enabling them to communicate with the ECM. This communication is essential for the ECM to monitor and control the truck’s systems, such as fuel injection, ignition timing, and emissions control. By facilitating this interaction, the wiring harness ensures that the truck operates efficiently and reliably 3.

Key Features

The 5262554 Electronic Control Module Wiring Harness is designed with several key features that enhance its performance and reliability. It is constructed using high-quality materials that are resistant to the harsh conditions found in heavy-duty truck environments. The harness is also designed to be durable and flexible, allowing it to withstand the vibrations and movements associated with truck operation. Additionally, it features precise wiring and connectors that ensure secure and reliable connections between components.

Benefits

The use of the 5262554 Electronic Control Module Wiring Harness offers several benefits. It contributes to improved engine performance by ensuring that the ECM can accurately monitor and control engine functions. This results in enhanced fuel efficiency, as the engine operates more efficiently. Furthermore, the reliable communication facilitated by the wiring harness increases the overall reliability of the truck’s electronic systems, reducing the likelihood of malfunctions and improving uptime.

Troubleshooting and Maintenance

To ensure the optimal performance and longevity of the 5262554 Electronic Control Module Wiring Harness, regular maintenance and troubleshooting practices are recommended. Inspecting the harness for signs of wear, corrosion, or damage can help identify potential issues before they lead to system failures. Additionally, ensuring that all connections are secure and free from debris can prevent communication errors. If issues arise, consulting the vehicle’s service manual or a professional technician can provide guidance on troubleshooting and repairs.

Cummins Overview

Cummins is a well-established manufacturer in the automotive and heavy-duty truck industry, known for its commitment to innovation and quality. With a history of producing reliable and high-performance components, Cummins has earned a reputation for excellence. The company’s dedication to advancing technology and meeting the needs of its customers is evident in its product offerings, including the 5262554 Electronic Control Module Wiring Harness.

Electronic Control Module Wiring Harness (Part 5262554) Compatibility with Cummins Engines

The Electronic Control Module (ECM) Wiring Harness, part number 5262554, manufactured by Cummins, is designed to interface seamlessly with a range of Cummins engines. This wiring harness is crucial for ensuring the proper electrical connectivity between the ECM and the engine’s various control units and sensors.

ISB/ISD6.7 CM2150 SN

The ISB/ISD6.7 CM2150 SN engines are equipped with the ECM Wiring Harness 5262554 to facilitate the transmission of critical data between the ECM and the engine’s electronic control units. This harness is engineered to withstand the operational demands of these engines, ensuring reliable performance and diagnostics.

ISBE CM2150

Similar to the ISB/ISD6.7 CM2150 SN, the ISBE CM2150 engine also utilizes the ECM Wiring Harness 5262554. This harness is integral to the engine’s electronic management system, providing the necessary electrical pathways for the ECM to communicate with other engine components effectively.

ISBE4 CM850

The ISBE4 CM850 engine is another model that benefits from the ECM Wiring Harness 5262554. This harness ensures that the ECM can accurately receive and send data to the engine’s sensors and actuators, maintaining optimal engine performance and efficiency.

Grouping of Engines

The ISB/ISD6.7 CM2150 SN and ISBE CM2150 engines share a common platform and thus have similar wiring harness requirements. The ECM Wiring Harness 5262554 is designed to fit both these engines, ensuring compatibility and ease of installation. The ISBE4 CM850, while distinct, also relies on this wiring harness for its electronic control needs, highlighting the versatility and broad applicability of the part across different engine models.

Role of Part 5262554 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified as part 5262554, serves as the vital connective tissue within modern engine systems. This harness is responsible for facilitating communication and power distribution between the ECM and various engine components.

Integration with Engine Components

-

Sensors: The harness connects an array of sensors—such as the Mass Air Flow (MAF) sensor, Manifold Absolute Pressure (MAP) sensor, and Oxygen (O2) sensors—to the ECM. These sensors provide real-time data on air intake, fuel mixture, and exhaust emissions, allowing the ECM to make precise adjustments for optimal performance.

-

Actuators: It also links actuators like the throttle body, fuel injectors, and variable valve timing (VVT) solenoids to the ECM. This ensures that the ECM’s commands are executed accurately, maintaining engine efficiency and responsiveness.

-

Ignition System: The harness plays a key role in connecting the ignition coils and spark plugs to the ECM. This enables the ECM to control the timing and intensity of the spark, crucial for combustion efficiency and engine power.

-

Fuel System: By connecting the fuel pump, fuel pressure regulator, and fuel injectors, the harness allows the ECM to manage fuel delivery precisely. This ensures the right amount of fuel is delivered at the right time, optimizing both performance and fuel economy.

-

Emission Control Systems: Components like the Exhaust Gas Recirculation (EGR) valve and the catalytic converter rely on the ECM Wiring Harness for operation. The harness ensures that these systems function within regulatory limits, reducing harmful emissions.

-

Battery and Alternator: The harness also facilitates the connection between the battery, alternator, and the ECM. This ensures that the ECM receives a stable power supply, essential for consistent engine operation and data processing.

Summary

In essence, the ECM Wiring Harness (part 5262554) is indispensable in modern engine systems. It ensures seamless communication and power distribution between the ECM and a multitude of engine components, thereby playing a significant role in maintaining engine performance, efficiency, and compliance with emission standards.

Conclusion

The 5262554 Electronic Control Module Wiring Harness by Cummins is a critical component in the electronic systems of heavy-duty trucks. Its role in facilitating communication and power distribution between the ECM and various engine components ensures optimal engine performance, efficiency, and compliance with emission standards. Regular maintenance and troubleshooting practices are essential to ensure the longevity and reliability of this part.

-

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning, 2011.

↩ -

Parikyan, Tigran Ed. Advances in Engine and Powertrain Research and Technology. Springer Nature, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.