FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

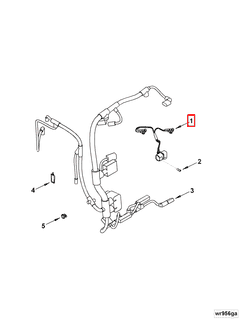

The 5291469 Electronic Control Module (ECM) Wiring Harness, manufactured by Cummins, is a vital component in the operation of commercial trucks. Cummins, a well-established name in the industry, is renowned for its high-quality engine and powertrain solutions. The 5291469 Wiring Harness is integral to the electrical system of commercial trucks, facilitating communication between the ECM and various truck systems.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a network of wires and connectors that link the ECM to other electronic components within a truck’s electrical system. This harness includes various components such as wires, connectors, and terminals. It functions by transmitting signals and power between the ECM and other systems, ensuring that the truck operates efficiently and effectively 1.

Role of the 5291469 Electronic Control Module Wiring Harness in Truck Operation

The 5291469 Wiring Harness plays a specific role in the operation of commercial trucks by enabling the ECM to communicate with and control various truck systems. This includes the engine, transmission, brakes, and other critical components. The harness ensures that data and power are accurately transmitted, allowing for precise control and monitoring of truck operations 2.

Key Features of the 5291469 Wiring Harness

The 5291469 Wiring Harness is designed with several key features that enhance its performance and reliability. These include a robust construction using high-quality materials, precise engineering to ensure compatibility with Cummins ECMs, and a design that protects against environmental factors such as moisture and vibration. These features contribute to the harness’s durability and efficiency in demanding commercial truck applications 3.

Benefits of Using the 5291469 Wiring Harness

Using the 5291469 Wiring Harness offers several benefits. It provides improved efficiency by ensuring reliable communication between the ECM and other truck systems. This leads to better overall performance and fuel efficiency. Additionally, the harness’s robust design contributes to its reliability, reducing the likelihood of failures and downtime. Furthermore, its high-quality construction can offer cost-saving advantages by minimizing the need for frequent replacements or repairs 4.

Troubleshooting the 5291469 Wiring Harness

When troubleshooting the 5291469 Wiring Harness, it is important to follow systematic diagnostic procedures. This includes checking for visible signs of damage, such as frayed wires or corroded connectors, and using diagnostic tools to identify any electrical issues. Potential solutions may involve repairing or replacing damaged components, ensuring all connections are secure, and verifying that the harness is correctly installed.

Maintenance of the 5291469 Wiring Harness

Regular maintenance of the 5291469 Wiring Harness is crucial for ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, cleaning connectors to prevent corrosion, and ensuring that all connections are tight and secure. Adhering to a maintenance schedule can help identify potential issues before they lead to more significant problems, thereby extending the harness’s lifespan.

Cummins: Manufacturer Overview

Cummins is a leading manufacturer in the commercial truck industry, known for its innovative engine and powertrain solutions. With a history spanning over a century, Cummins has built a reputation for quality, reliability, and performance. The company offers a wide range of products and services designed to meet the diverse needs of commercial truck operators, ensuring that their vehicles run efficiently and reliably.

Electronic Control Module Wiring Harness for Cummins Engines

The Electronic Control Module (ECM) Wiring Harness, part number 5291469, is a critical component for the proper functioning of several Cummins engines. This wiring harness is designed to ensure seamless communication between the ECM and other electronic control units within the engine system.

ISB/ISD6.7 CM2150 SN Engines

The ISB/ISD6.7 CM2150 SN engines benefit significantly from the ECM Wiring Harness. This part is integral in managing the complex electrical pathways that control engine performance, ensuring that all electronic components are correctly powered and communicating effectively. The harness is engineered to withstand the rigors of heavy-duty applications, providing reliability and durability in demanding environments.

ISBE CM2150 and ISBE4 CM850 Engines

Similarly, the ISBE CM2150 and ISBE4 CM850 engines also utilize the ECM Wiring Harness part number 5291469. This harness is essential for maintaining the integrity of the electronic control systems in these engines. It ensures that the ECM can effectively manage engine parameters, optimize performance, and enhance fuel efficiency. The design of the harness is tailored to fit the specific electrical architecture of these engines, ensuring a precise and reliable connection.

The ECM Wiring Harness is a critical component for the ISB/ISD6.7 CM2150 SN, ISBE CM2150, and ISBE4 CM850 engines. Its role in facilitating communication between the ECM and other electronic control units is vital for the overall performance and reliability of these engines.

Role of Part 5291469 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified as part 5291469, is integral to the operation of modern engine systems. This component serves as the vital link between the ECM and various engine sensors, actuators, and other electronic components.

Integration with Engine Sensors

The ECM Wiring Harness facilitates communication between the ECM and engine sensors such as the Mass Air Flow (MAF) sensor, Manifold Absolute Pressure (MAP) sensor, and Oxygen (O2) sensors. These sensors provide real-time data on air intake, fuel mixture, and exhaust emissions, allowing the ECM to make precise adjustments for optimal engine performance.

Connection to Actuators

Actuators like the fuel injectors, throttle body, and variable valve timing (VVT) solenoids rely on the ECM Wiring Harness to receive signals from the ECM. This ensures that fuel delivery, air intake, and valve timing are synchronized for efficient combustion and reduced emissions.

Interaction with Other Electronic Components

The harness also connects the ECM to other critical components such as the transmission control module (TCM), anti-lock braking system (ABS) module, and powertrain control module (PCM). This interconnectivity allows for coordinated control of various vehicle systems, enhancing overall drivability and safety.

Role in Diagnostic Systems

In addition to facilitating real-time data exchange, the ECM Wiring Harness is essential for onboard diagnostics (OBD). It allows the ECM to communicate with diagnostic tools, enabling mechanics to retrieve error codes, monitor sensor readings, and perform system tests. This capability is invaluable for troubleshooting and maintaining engine health.

Support for Advanced Features

Modern engine systems often include advanced features such as start-stop technology, cylinder deactivation, and hybrid powertrains. The ECM Wiring Harness supports these features by ensuring seamless communication between the ECM and the additional components required for their operation.

Conclusion

In summary, the ECM Wiring Harness (part 5291469) is a foundational element in the engine system, enabling the ECM to effectively manage and optimize engine performance through its connections to sensors, actuators, and other electronic modules. Its robust design, precise engineering, and comprehensive integration with engine systems make it a critical component for the reliable operation of commercial trucks.

-

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩ -

Eret, A. (2024). Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Goodnight, N., & Van Gelder, K. (2018). Automotive Braking Systems. Jones & Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.