FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

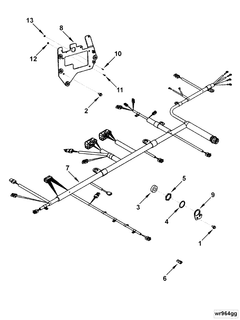

The Electronic Control Module Wiring Harness (5302000) by Cummins is a vital component in the operation of commercial trucks. This wiring harness serves as the backbone of the truck’s electronic system, facilitating communication between various electronic components and ensuring the smooth operation of the vehicle.

Basic Concepts

Electronic Control Module Wiring Harnesses are integral to vehicle electronics and communication systems. They consist of a network of wires and connectors that link different electronic components, allowing them to communicate and share data. This communication is crucial for the proper functioning of the vehicle’s systems, including the engine, transmission, and various sensors 1.

Purpose and Functionality

The 5302000 Electronic Control Module Wiring Harness plays a significant role in the operation of a truck by connecting various electronic components and facilitating communication between them. It ensures that data is accurately transmitted between the Electronic Control Module (ECM) and other parts of the truck’s electronic system, such as sensors, actuators, and the dashboard. This communication allows the ECM to monitor and control the truck’s performance, making adjustments as necessary to optimize efficiency and reliability.

Key Features

The 5302000 Electronic Control Module Wiring Harness is designed with several key features that enhance its performance and reliability. It is constructed using high-quality materials that are resistant to wear, corrosion, and environmental factors. The harness is also designed to be flexible and durable, allowing it to withstand the rigors of daily use in commercial trucking applications. Additionally, the harness is engineered to provide a secure and reliable connection between electronic components, ensuring consistent and accurate data transmission.

Benefits

The 5302000 Electronic Control Module Wiring Harness offers several benefits to truck operators. By facilitating accurate and reliable communication between electronic components, it helps to improve engine performance, enhance fuel efficiency, and increase the reliability of the truck’s electronic systems. This, in turn, can lead to reduced maintenance costs, increased uptime, and improved overall vehicle performance 2.

Installation and Integration

Proper installation and integration of the 5302000 Electronic Control Module Wiring Harness are crucial to ensure optimal performance and longevity. When installing the harness, it is important to follow the manufacturer’s guidelines and recommendations to ensure a secure and reliable connection between electronic components. This may include using the appropriate tools and techniques, as well as taking necessary precautions to protect the harness from damage during installation.

Troubleshooting and Maintenance

To ensure the optimal performance and longevity of the 5302000 Electronic Control Module Wiring Harness, it is important to perform routine maintenance and address any issues that may arise. Common issues with wiring harnesses can include loose connections, damaged wires, or corrosion. To troubleshoot these issues, it is recommended to visually inspect the harness for any signs of damage or wear, and to use diagnostic tools to identify any communication errors or data transmission issues. Regular maintenance, such as cleaning and inspecting the harness, can help to prevent these issues and ensure the continued reliable operation of the truck’s electronic system 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history dating back to 1919, Cummins has established a strong reputation in the automotive industry for producing high-quality, reliable, and innovative products. The company offers a wide range of products and services, including engines, powertrains, and aftermarket parts, serving customers in various industries such as transportation, construction, agriculture, and power generation.

Role of Part 5302000 Electronic Control Module Wiring Harness in Engine Systems

The Part 5302000 Electronic Control Module (ECM) Wiring Harness is an integral component in the orchestration of various engine systems. It serves as the vital conduit that facilitates communication and power distribution between the ECM and other critical engine components.

Integration with Engine Control Wiring

The ECM Wiring Harness interfaces directly with the Engine Control Wiring, which is responsible for transmitting signals and power to and from the ECM. This connection ensures that the ECM receives accurate data from sensors such as the Mass Air Flow (MAF) sensor, Manifold Absolute Pressure (MAP) sensor, and Oxygen (O2) sensors. In turn, the ECM can send precise commands to actuators like the fuel injectors, ignition coils, and variable valve timing (VVT) solenoids.

Communication with Harness

The harness itself is a network of wires that extends throughout the engine bay and into the vehicle’s interior. It connects the ECM to a multitude of components, including but not limited to:

- Sensors: Temperature sensors, crankshaft position sensor, camshaft position sensor, and throttle position sensor.

- Actuators: Electric fuel pump, idle air control valve, and electronic throttle control system.

- Other Modules: Transmission Control Module (TCM), Anti-lock Braking System (ABS) module, and Body Control Module (BCM).

This comprehensive connectivity allows the ECM to monitor and adjust engine performance in real-time, ensuring optimal operation under varying conditions.

Functional Synergy

The synergy between the ECM Wiring Harness and the engine control wiring is paramount for the seamless operation of the engine. The harness not only carries data but also provides the necessary voltage and ground connections required for the sensors and actuators to function. This dual role of data transmission and power supply underscores the importance of the ECM Wiring Harness in maintaining engine efficiency and reliability.

Conclusion

The 5302000 Electronic Control Module Wiring Harness by Cummins is a critical component in the operation of commercial trucks and various engine systems. Its role in facilitating communication and power distribution between the ECM and other engine components ensures optimal engine performance, efficiency, and reliability. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this Cummins part and ensure the continued reliable operation of the vehicle’s electronic system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.