5318179

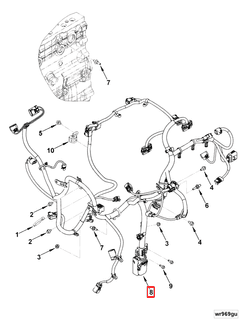

Electronic Control Module Wiring Harness

Cummins®

BACK ORDERED

Please contact us for information on lead time

FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Electronic Control Module Wiring Harness (Part #5318179) by Cummins is a critical component in the electronic systems of heavy-duty trucks. Manufactured by Cummins, a reputable name in the automotive industry, this wiring harness is designed to ensure efficient and reliable communication between various electronic components within the vehicle.

Basic Concepts

Electronic Control Module Wiring Harnesses serve as the backbone of a vehicle’s electronic and communication systems. They facilitate the transmission of signals and power between the Electronic Control Module (ECM) and other electronic components, ensuring that all systems operate in harmony. Understanding the principles behind these harnesses is fundamental to grasping their role in modern vehicle electronics 1.

Purpose and Functionality

The 5318179 Electronic Control Module Wiring Harness plays a significant role in the operation of a truck by connecting various electronic components and enabling communication within the vehicle’s systems. It acts as a conduit for signals and power, allowing the ECM to monitor and control engine functions, transmission operations, and other critical systems. This connectivity is vital for the overall performance and efficiency of the truck 2.

Key Features

The 5318179 Electronic Control Module Wiring Harness is characterized by its robust design and high-quality construction materials. It is engineered to withstand the harsh conditions typical of heavy-duty truck environments. Unique features include corrosion-resistant connectors, durable insulation, and a layout that minimizes the risk of electrical interference. These characteristics contribute to the harness’s performance and reliability 3.

Benefits

The 5318179 Electronic Control Module Wiring Harness offers several benefits, including enhanced efficiency and reliability in the truck’s electronic systems. Its design ensures seamless compatibility with Cummins engines and other components, promoting optimal vehicle performance. The harness’s durability and resistance to environmental factors further contribute to its reliability and longevity.

Installation and Integration

Proper installation and integration of the 5318179 Electronic Control Module Wiring Harness into a truck’s electronic system are crucial for its effective operation. It is important to follow manufacturer guidelines to ensure correct placement and secure connections. Precautions should be taken to protect the harness from physical damage and environmental factors during installation.

Troubleshooting and Maintenance

Regular maintenance and prompt troubleshooting are key to ensuring the continued optimal performance of the 5318179 Electronic Control Module Wiring Harness. Common issues may include loose connections, corrosion, or damage to the harness. Inspections and cleaning can prevent many problems, while careful diagnosis is required for more complex issues to ensure accurate repairs.

Cummins Overview

Cummins, the manufacturer of the 5318179 Electronic Control Module Wiring Harness, has a long-standing reputation in the automotive industry for quality and innovation. With a history of producing reliable and high-performance components, Cummins is committed to advancing technology and meeting the needs of its customers in the heavy-duty truck sector 4.

Role of Part 5318179 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified by part number 5318179, is an integral component in the orchestration of various engine systems. This harness serves as the vital link between the ECM and numerous engine components, ensuring seamless communication and operation.

Integration with Engine Components

-

Sensors and Actuators: The ECM Wiring Harness facilitates the connection between the ECM and an array of sensors and actuators. These include the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and various actuators such as the fuel injectors and throttle position actuator. By providing a robust and reliable pathway for data transmission, the harness ensures that the ECM receives accurate readings and can issue precise commands.

-

Fuel System: Within the fuel system, the harness connects to components such as the fuel pump, fuel pressure regulator, and fuel injectors. It enables the ECM to monitor fuel delivery and pressure, adjusting injector pulse width and fuel pump operation to maintain optimal fuel-air mixture.

-

Ignition System: The harness interfaces with ignition components including the ignition coil, spark plugs, and camshaft position sensor. This allows the ECM to control ignition timing and spark intensity, enhancing combustion efficiency and engine performance.

-

Emission Control System: Components such as the Exhaust Gas Recirculation (EGR) valve, catalytic converter, and various emission sensors are connected via the ECM Wiring Harness. This ensures that the ECM can regulate emissions, comply with environmental standards, and optimize engine operation for reduced pollutants.

-

Transmission Control: In engines equipped with automatic transmissions, the harness connects to the Transmission Control Module (TCM) and various transmission sensors. This integration allows the ECM to communicate with the TCM, ensuring smooth gear shifts and optimal transmission performance based on driving conditions.

-

Engine Cooling System: The harness also links to the engine coolant temperature sensor and the engine control thermostat. This enables the ECM to monitor coolant temperature and adjust engine operation to prevent overheating and ensure efficient engine performance.

-

Battery and Charging System: Connections to the battery, alternator, and voltage regulator are established through the ECM Wiring Harness. This allows the ECM to monitor battery voltage and charging system performance, ensuring consistent power supply to all engine components.

Enhanced Engine Performance and Reliability

By providing a comprehensive network of connections, the ECM Wiring Harness part 5318179 plays a significant role in enhancing engine performance, fuel efficiency, and overall reliability. It ensures that the ECM can effectively manage and coordinate the operation of all connected components, leading to a more responsive and efficient engine system.

Conclusion

The 5318179 Electronic Control Module Wiring Harness is a vital component in the electronic systems of heavy-duty trucks, ensuring efficient and reliable communication between various electronic components. Its robust design, high-quality construction, and comprehensive network of connections contribute to enhanced engine performance, fuel efficiency, and overall reliability. Proper installation, regular maintenance, and prompt troubleshooting are essential for the continued optimal performance of this Cummins part.

-

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Gijs Mom. (2023). The Evolution of Automotive Engineering: A Handbook. SAE International.

↩ -

Konrad Reif. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for L9 CM2670 L135C, Bulletin Number 5579956.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.