5332299

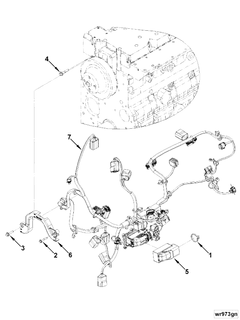

Electronic Control Module Wiring Harness

Cummins®

IN STOCK

2 are currently available

Ships within 1 business day

FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Electronic Control Module Wiring Harness, part number 5332299, is a critical component for the seamless operation of various Cummins engines. This wiring harness is designed to interface with the Electronic Control Module (ECM) and other electronic components, ensuring that electrical signals are transmitted accurately and efficiently 1.

Basic Concepts

The Electronic Control Module (ECM) serves as the brain of the truck, managing and regulating various functions to optimize performance. It processes data from sensors and other inputs to control engine operations, transmission shifts, and other critical functions. The wiring harness, on the other hand, acts as the nervous system, connecting the ECM to sensors, actuators, and other components throughout the truck. This network of wires and connectors enables the ECM to receive data from and send commands to different parts of the vehicle, ensuring coordinated and efficient operation 2.

Purpose of the 5332299 Electronic Control Module Wiring Harness

The 5332299 Wiring Harness plays a significant role in the operation of a truck by providing a reliable pathway for electrical signals between the ECM and other components. It ensures that the ECM can effectively monitor and control various systems within the truck, such as the engine, transmission, and braking system. This communication is crucial for the truck’s performance, efficiency, and safety 3.

Key Features

The 5332299 Wiring Harness is characterized by its robust design and high-quality materials, which contribute to its durability and performance. It is engineered to withstand the harsh conditions often encountered in heavy-duty truck operations, including extreme temperatures, vibrations, and exposure to chemicals. The harness is constructed using corrosion-resistant materials and is designed to minimize electrical resistance, ensuring efficient signal transmission. Additionally, its modular design allows for easy integration with the truck’s existing systems, enhancing its versatility 4.

Benefits

Utilizing the 5332299 Wiring Harness offers several advantages. Its design enhances the reliability of the electrical system, reducing the likelihood of failures and improving overall truck performance. The ease of installation, thanks to its modular design, minimizes downtime during maintenance or upgrades. Furthermore, the harness’s durability ensures long-term operation without the need for frequent replacements, contributing to cost efficiency 5.

Installation Process

Installing the 5332299 Wiring Harness involves several steps to ensure proper integration with the truck’s systems. Begin by disconnecting the battery to prevent electrical shocks. Next, route the harness through the designated pathways, ensuring it is secured in place to avoid damage from vibrations. Connect the harness to the ECM and other components, following the manufacturer’s instructions for polarity and connection points. Finally, reattach the battery and test the system to confirm proper installation 6.

Common Issues and Troubleshooting

Common issues with the 5332299 Wiring Harness may include loose connections, damaged wires, or corrosion at connection points. To troubleshoot, inspect the harness for visible damage or wear. Ensure all connections are secure and free from corrosion. If issues persist, use a multimeter to test for continuity and identify any breaks in the wiring. Addressing these issues promptly can prevent more significant problems and ensure the truck’s continued reliable operation 7.

Maintenance Tips

Regular maintenance of the 5332299 Wiring Harness is key to ensuring its longevity and optimal performance. Inspect the harness during routine maintenance checks for signs of wear, damage, or corrosion. Clean connection points to remove any dirt or debris that could interfere with signal transmission. Additionally, ensure the harness is properly secured and protected from physical damage. Following these maintenance practices can help prevent issues and extend the life of the wiring harness 8.

Cummins Overview

Cummins, a renowned name in the automotive industry, has a rich history of innovation and quality in manufacturing truck components. Established with a commitment to excellence, Cummins has consistently delivered reliable and high-performance parts for heavy-duty trucks. Their focus on research and development ensures that their products, like the 5332299 Wiring Harness, meet the demanding requirements of modern truck operations, contributing to the efficiency, reliability, and safety of vehicles on the road 9.

Conclusion

The Electronic Control Module Wiring Harness, part number 5332299, is indispensable for the efficient and reliable operation of Cummins engines. Its role in facilitating communication between the ECM and various engine components underscores its importance in modern automotive systems. By ensuring precise control over engine operations and enhancing overall vehicle performance, this Cummins part exemplifies the commitment to quality and innovation that Cummins is known for.

-

Sheng, Gang. Vehicle Noise, Vibration and Sound Quality. SAE International, 2012.

↩ -

Thompson, Rob. Automotive Maintenance: Light Repair. Cengage Learning, 2019.

↩ -

Huzij, Robert, et al. Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning, 2019.

↩ -

Cummins Inc. Service Manual (5613391). QSK38 CM2350 K125, Cummins Inc.

↩ -

Sheng, Gang. Vehicle Noise, Vibration and Sound Quality. SAE International, 2012.

↩ -

Thompson, Rob. Automotive Maintenance: Light Repair. Cengage Learning, 2019.

↩ -

Huzij, Robert, et al. Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning, 2019.

↩ -

Cummins Inc. Service Manual (5613391). QSK38 CM2350 K125, Cummins Inc.

↩ -

Sheng, Gang. Vehicle Noise, Vibration and Sound Quality. SAE International, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.