5336400

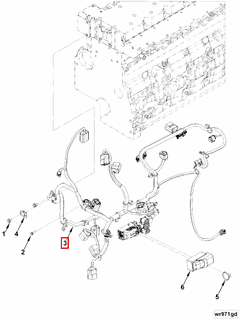

Electronic Control Module Wiring Harness

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Electronic Control Module Wiring Harness (part 5336400) by Cummins is a vital component in the operation of commercial trucks. This wiring harness is designed to facilitate the connection between the Electronic Control Module (ECM) and various sensors and components within the truck. Its role is significant in ensuring that the ECM can effectively manage and optimize the truck’s performance 1.

Basic Concepts

The Electronic Control Module (ECM) serves as the brain of the truck, processing data from various sensors and components to manage engine performance, fuel efficiency, and emissions. The wiring harness is a network of wires and connectors that link the ECM to these sensors and components, enabling the transmission of data and control signals. This connection is essential for the ECM to monitor and adjust the truck’s operations in real-time 2.

Purpose and Functionality

The 5336400 Wiring Harness is specifically designed to facilitate seamless communication between the ECM and other truck systems. By providing a reliable pathway for data and control signals, it ensures that the ECM can effectively manage the truck’s performance and efficiency. This wiring harness plays a role in maintaining the optimal operation of the truck by ensuring that all components are in sync with the ECM’s directives 3.

Key Features

The 5336400 Wiring Harness is characterized by several key features that enhance its performance and durability. Its design incorporates high-quality materials that are resistant to the harsh conditions often encountered in commercial trucking. The harness is engineered to withstand vibrations, temperature fluctuations, and exposure to chemicals, ensuring long-lasting reliability. Additionally, it features robust connectors and protective coatings that safeguard against corrosion and wear, contributing to its durability 4.

Benefits

The implementation of the 5336400 Wiring Harness in commercial trucks offers several benefits. It contributes to improved engine performance by ensuring that the ECM receives accurate and timely data from all connected sensors and components. This leads to more precise control over engine operations, resulting in enhanced fuel efficiency. Furthermore, the reliable data transmission facilitated by the wiring harness ensures that the ECM can make informed decisions, leading to optimal truck performance and reduced downtime 5.

Troubleshooting and Maintenance

Regular maintenance of the Electronic Control Module Wiring Harness is important for ensuring its longevity and optimal performance. Inspecting the harness for signs of wear, corrosion, or damage can help identify potential issues before they lead to more significant problems. Troubleshooting common issues may involve checking for loose connections, damaged wires, or faulty sensors. Addressing these issues promptly can prevent disruptions in the ECM’s communication with the truck’s systems, maintaining the truck’s performance and efficiency 6.

About Cummins

Cummins Inc. is a global leader in the design, manufacture, and distribution of diesel and alternative fuel engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry. The company’s commitment to innovation is evident in its continuous development of advanced engine technologies and components, including the 5336400 Electronic Control Module Wiring Harness. Cummins’ expertise in diesel engine manufacturing and its dedication to enhancing the performance and efficiency of commercial trucks underscore its position as a leader in the industry 7.

Conclusion

The Electronic Control Module Wiring Harness (part 5336400) by Cummins is a critical component for the efficient and reliable operation of commercial trucks. Its role in facilitating communication between the ECM and various truck systems ensures optimal performance, enhanced fuel efficiency, and reduced downtime. Regular maintenance and prompt troubleshooting of this part are essential for maintaining the truck’s performance and efficiency.

-

Kirk T Van Gelder, Fundamentals of Automotive Technology Principles and Practice, Jones Bartlett Learning, 2018.

↩ -

Sean Bennett, Modern Diesel Technology Light Duty Diesels, Cengage Learning, 2012.

↩ -

Michael Hilgers, Transmissions and Drivetrain Design, Springer Vieweg, 2022.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 4388737, L9.5 L117.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 4388737, L9.5 L117.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 4388737, L9.5 L117.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 4388737, L9.5 L117.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.