FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

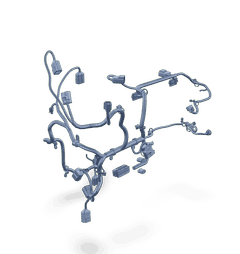

The Electronic Control Module Wiring Harness (Part #5336402) by Cummins is a vital component in the electrical system of heavy-duty trucks. This wiring harness facilitates the connection between the Electronic Control Module (ECM) and various sensors and actuators throughout the vehicle. Manufactured by Cummins, a reputable name in the automotive industry, this wiring harness is designed to enhance the performance, efficiency, and reliability of heavy-duty trucks 2.

Basic Concepts

Electronic Control Module Wiring Harnesses are integral to the electronics and communication systems within vehicles. They serve as the conduit for electrical signals between the ECM and other components, enabling the ECM to monitor and control various functions of the truck. This includes engine performance, fuel efficiency, and emissions control. The wiring harness is composed of multiple wires, each serving a specific purpose in transmitting data and power 1.

Purpose and Functionality

This Cummins part plays a significant role in the operation of a truck by connecting the ECM to various sensors and actuators. This connection allows the ECM to receive data from sensors regarding engine conditions, vehicle speed, and other operational parameters. Based on this data, the ECM sends signals to actuators to adjust engine performance, fuel injection timing, and other critical functions to optimize operation.

Key Features

The 5336402 is characterized by its robust design and high-quality materials. It is engineered to withstand the harsh conditions typical of heavy-duty truck environments, including extreme temperatures and vibrations. The harness is constructed using durable materials that resist corrosion and wear, ensuring long-term reliability. Additionally, its design includes features that enhance signal integrity and reduce the risk of electrical interference.

Benefits

The implementation of the 5336402 in a truck’s electrical system offers several benefits. It contributes to improved engine performance by ensuring precise communication between the ECM and vehicle components. This precision leads to enhanced fuel efficiency, as the ECM can make real-time adjustments to optimize fuel consumption. Furthermore, the reliability of the wiring harness reduces the likelihood of electrical failures, contributing to the overall dependability of the truck.

Installation and Integration

Proper installation and integration of the 5336402 into a truck’s electrical system are crucial for its effective operation. It is important to follow manufacturer guidelines to ensure that all connections are secure and that the harness is properly routed to avoid damage from heat, friction, or moving parts. Careful consideration should be given to the harness’s placement to protect it from environmental factors and mechanical stress.

Troubleshooting and Maintenance

Regular maintenance and prompt troubleshooting of the 5336402 are important for its longevity and optimal performance. Inspecting the harness for signs of wear, corrosion, or damage and addressing any issues immediately can prevent more significant problems. Additionally, ensuring that all connections are clean and secure can help maintain the integrity of the electrical signals transmitted through the harness.

Cummins Overview

Cummins is a well-established manufacturer in the automotive industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance components, Cummins has earned a reputation for excellence. The company’s dedication to advancing technology and improving the efficiency and reliability of automotive components is evident in its products, including the 5336402 2.

Electronic Control Module Wiring Harness for Cummins Engines

The Electronic Control Module (ECM) Wiring Harness, part number 5336402, is a critical component for the proper functioning of several Cummins engines. This wiring harness is designed to facilitate the communication between the ECM and various sensors and actuators within the engine system. It ensures that the ECM can accurately monitor and control engine performance, emissions, and other vital functions.

ISB6.7 and CM2350 Engines

The ISB6.7 and CM2350 engines are both high-performance diesel engines that benefit significantly from the ECM Wiring Harness. These engines are widely used in heavy-duty applications, including commercial trucks, construction equipment, and agricultural machinery. The wiring harness ensures that the ECM can effectively manage fuel injection, turbocharging, and other critical systems, enhancing overall engine efficiency and reliability.

B101 Engine

The B101 engine, another robust Cummins engine, also relies on the ECM Wiring Harness for seamless operation. This engine is typically found in medium-duty vehicles and industrial applications. The wiring harness plays a crucial role in maintaining the engine’s performance by ensuring that the ECM can accurately interpret data from various sensors and send appropriate commands to the engine’s actuators.

Compatibility and Importance

The ECM Wiring Harness is engineered to be compatible with these Cummins engines, providing a reliable and efficient means of communication between the ECM and other engine components. This compatibility is essential for maintaining the engine’s performance, ensuring compliance with emissions standards, and preventing potential failures or malfunctions. Proper installation and maintenance of the wiring harness are critical to the engine’s longevity and efficiency.

Role of Part 5336402 Electronic Control Module Wiring Harness in Engine Systems

The part 5336402 Electronic Control Module (ECM) Wiring Harness is an integral component in the orchestration of engine systems. It serves as the vital link between the ECM and various engine components, facilitating seamless communication and data exchange.

Integration with Engine Components

-

Sensors: The harness connects various sensors—such as the oxygen sensor, mass airflow sensor, and throttle position sensor—to the ECM. This allows the ECM to receive real-time data on engine performance, enabling it to make precise adjustments for optimal operation.

-

Actuators: It interfaces with actuators like the fuel injectors, ignition coils, and variable valve timing solenoids. By transmitting signals from the ECM, the harness ensures these components operate in harmony with the engine’s requirements.

-

Power Supply: The harness provides a consistent power supply to the ECM and other electronic components, ensuring they function reliably under varying conditions.

-

Grounding: It establishes essential ground connections, which are critical for the proper functioning of electronic components and for preventing electrical noise that could interfere with signal integrity.

-

Communication Networks: In modern engine systems, the harness may also connect to communication networks such as CAN (Controller Area Network) buses, allowing for integrated control and diagnostics across multiple systems.

Functional Synergy

The ECM Wiring Harness plays a pivotal role in the functional synergy of engine systems. It ensures that all electronic components work in concert, allowing the ECM to execute complex algorithms that enhance engine efficiency, performance, and emissions control.

By providing a robust and reliable connection infrastructure, the harness supports the ECM’s ability to adapt to changing conditions, whether it’s adjusting fuel delivery, ignition timing, or emissions controls, thereby contributing to the overall reliability and performance of the engine system.

Conclusion

The 5336402 Electronic Control Module Wiring Harness by Cummins is a critical component in the electrical system of heavy-duty trucks. Its robust design, high-quality materials, and precise functionality contribute to improved engine performance, enhanced fuel efficiency, and increased reliability. Proper installation, maintenance, and troubleshooting are essential for ensuring the longevity and optimal performance of this part. Cummins’ commitment to quality and innovation is reflected in the design and functionality of the 5336402, making it a reliable choice for heavy-duty applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.