FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

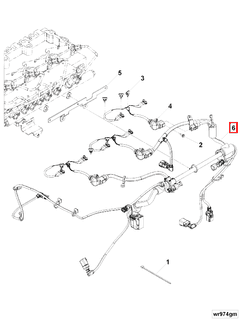

The Electronic Control Module Wiring Harness (Part #5361689) by Cummins is a vital component in the realm of heavy-duty trucks. This wiring harness is designed to facilitate communication between the Electronic Control Module (ECM) and various sensors and actuators within the vehicle. Cummins, a renowned manufacturer in the automotive industry, produces this part with a focus on reliability and performance, ensuring that it meets the demanding requirements of heavy-duty applications.

Basic Concepts

Electronic Control Module Wiring Harnesses are fundamental to the operation of modern vehicle electronics and engine management systems. These harnesses serve as the conduit through which the ECM receives data from sensors and sends commands to actuators. This bidirectional flow of information allows the ECM to monitor and adjust engine performance in real-time, optimizing efficiency and ensuring smooth operation 1.

Purpose and Functionality

The 5361689 Electronic Control Module Wiring Harness plays a significant role in the operation of a truck by connecting the ECM to a network of sensors and actuators. This connection enables the ECM to gather data on engine conditions, such as temperature, pressure, and fuel levels, and to control various engine functions, including fuel injection, ignition timing, and emissions systems. By facilitating this communication, the wiring harness contributes to the overall performance and efficiency of the engine 2.

Key Features

The 5361689 Electronic Control Module Wiring Harness is characterized by its robust design and high-quality construction materials. It is engineered to withstand the harsh conditions typical of heavy-duty truck environments, including exposure to vibrations, temperature fluctuations, and moisture. The harness is constructed from durable materials that ensure longevity and reliability, and it features precise wiring and connections to maintain signal integrity and prevent electrical interference.

Benefits

The implementation of the 5361689 Electronic Control Module Wiring Harness in a truck’s engine system offers several advantages. It contributes to improved engine performance by enabling the ECM to make real-time adjustments based on sensor data. This results in enhanced fuel efficiency, as the engine operates more efficiently under varying conditions. Additionally, the reliable connection provided by the wiring harness increases the overall reliability of the engine system, reducing the likelihood of malfunctions and improving uptime 3.

Installation and Compatibility

Proper installation of the 5361689 Electronic Control Module Wiring Harness is crucial for ensuring its effective operation. Installation procedures should follow manufacturer guidelines to ensure secure and correct connections. Compatibility with different truck models and engine types is an important consideration, as the harness must be designed to interface correctly with the specific ECM and sensor/actuator configurations of the vehicle.

Troubleshooting and Maintenance

Common issues with the 5361689 Electronic Control Module Wiring Harness may include loose connections, damaged wires, or corrosion at connection points. Regular inspection and maintenance can help identify and address these issues before they lead to more significant problems. Troubleshooting tips include checking for secure connections, inspecting wires for signs of wear or damage, and cleaning connection points to prevent corrosion. Adhering to a maintenance schedule can ensure the longevity and optimal performance of the wiring harness.

Cummins Overview

Cummins is a well-established name in the automotive industry, known for its commitment to quality and innovation in the production of automotive components. With a rich history of providing reliable and high-performance parts, Cummins has built a reputation for excellence. The company’s dedication to advancing technology and meeting the needs of its customers is evident in its wide range of products, including the 5361689 Electronic Control Module Wiring Harness.

Cummins Engine Compatibility with Electronic Control Module Wiring Harness Part 5361689

The Electronic Control Module (ECM) Wiring Harness part number 5361689, manufactured by Cummins, is a critical component for ensuring the proper electrical connectivity between the ECM and various sensors and actuators within the engine system. This wiring harness is designed to facilitate seamless communication and control, enhancing the overall performance and reliability of the engine.

QSL9.3 CM2880 L113 Engines

The ECM Wiring Harness part 5361689 is compatible with the QSL9.3 CM2880 L113 engines. These engines are known for their robust design and efficiency, often used in heavy-duty applications where reliability and performance are paramount. The wiring harness ensures that the ECM can effectively manage engine operations, including fuel injection, ignition timing, and emissions control, by providing a secure and efficient electrical pathway.

The harness is engineered to withstand the harsh conditions typically encountered in these engines’ environments, ensuring longevity and consistent performance. Its design allows for easy installation and maintenance, which is crucial for minimizing downtime and maximizing productivity in industrial and commercial settings.

By integrating the ECM Wiring Harness part 5361689 into the QSL9.3 CM2880 L113 engines, users can expect improved engine diagnostics, enhanced control over engine functions, and better overall system integration. This compatibility underscores Cummins’ commitment to providing high-quality, reliable components that meet the demanding needs of modern engine applications.

Role of Part 5361689 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified by part number 5361689, is an integral component in the orchestration of various engine systems. This harness serves as the vital link between the ECM and multiple engine components, ensuring seamless communication and operation.

Integration with Engine Components

-

Sensors: The ECM Wiring Harness connects various sensors such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and Manifold Absolute Pressure (MAP) sensor to the ECM. These sensors provide real-time data on air intake, oxygen levels, and pressure within the intake manifold, allowing the ECM to make precise adjustments to fuel delivery and ignition timing.

-

Actuators: This harness also interfaces with actuators like the fuel injectors, throttle body, and variable valve timing (VVT) solenoids. By transmitting signals from the ECM, it enables these components to respond accordingly, optimizing engine performance and efficiency.

-

Ignition System: The harness facilitates communication between the ECM and the ignition system components, including the ignition coils and spark plugs. This ensures that the ignition timing is accurately controlled, contributing to smooth engine operation and reduced emissions.

-

Emission Control Systems: Components such as the Evaporative Emission Control (EVAP) system and the Exhaust Gas Recirculation (EGR) valve rely on the ECM Wiring Harness to receive commands from the ECM. This coordination helps in minimizing harmful emissions and ensuring compliance with environmental regulations.

-

Battery and Alternator: The harness also plays a role in connecting the ECM to the vehicle’s power sources, including the battery and alternator. This ensures that the ECM receives a stable power supply, which is essential for its operation and the overall electrical system’s reliability.

-

Communication Networks: In modern vehicles, the ECM Wiring Harness is part of a larger communication network that includes the Controller Area Network (CAN) bus. This network allows the ECM to share data with other control modules, such as the Transmission Control Module (TCM) and the Anti-lock Braking System (ABS) module, enhancing overall vehicle performance and safety.

By effectively linking the ECM to these diverse components, the 5361689 ECM Wiring Harness ensures that the engine operates efficiently, responds accurately to driving conditions, and maintains optimal performance across a range of operating scenarios.

Conclusion

The 5361689 Electronic Control Module Wiring Harness by Cummins is a critical component in the operation of heavy-duty trucks. Its robust design, high-quality construction, and compatibility with various engine systems make it an essential part for ensuring reliable and efficient engine performance. Proper installation, regular maintenance, and understanding its role in engine systems are key to maximizing the benefits of this Cummins part.

-

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.