This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3965953 Electronic Control Module (ECM) is a sophisticated component designed to manage and optimize the operation of commercial trucks. Its purpose is to regulate various systems within the truck, ensuring efficient performance and reliability. The significance of this Cummins part lies in its ability to enhance the overall functionality of the vehicle, contributing to better fuel efficiency, improved engine performance, and streamlined diagnostics 1.

Basic Concepts of Electronic Control Modules

An Electronic Control Module (ECM) is a computerized device that plays a central role in the management of vehicle systems. It processes data from various sensors and actuators, making real-time adjustments to ensure optimal performance. The ECM integrates with other components by receiving input signals, processing them, and sending output signals to control different systems within the vehicle 2.

Role of the 3965953 ECM in Truck Operation

The Cummins 3965953 ECM is integral to the operation of a truck, interacting with the engine, transmission, and other systems to maintain efficient performance. It monitors engine parameters such as fuel injection, air intake, and exhaust emissions, making necessary adjustments to optimize engine operation. Additionally, it communicates with the transmission control module to ensure smooth gear shifts and efficient power delivery. The ECM also interfaces with other systems, such as the braking system and emissions control, to enhance overall truck performance 3.

Key Features of the Cummins 3965953 ECM

The Cummins 3965953 ECM boasts several key features that contribute to its effectiveness. These include robust processing power, which allows it to handle complex calculations and data processing in real-time. It also has a substantial memory capacity, enabling it to store extensive data logs and diagnostic information. The ECM’s diagnostic capabilities are enhanced by its ability to detect and log fault codes, providing valuable information for troubleshooting. Additionally, it offers various connectivity options, allowing for easy integration with diagnostic tools and other systems.

Benefits of Using the Cummins 3965953 ECM

The Cummins 3965953 ECM offers several benefits that enhance truck operation. One of the primary advantages is improved fuel efficiency, as the ECM optimizes fuel delivery and combustion processes. This results in reduced fuel consumption and lower operating costs. Enhanced performance is another benefit, with the ECM ensuring that the engine operates at peak efficiency under various conditions. Better diagnostics are facilitated by the ECM’s ability to monitor system performance and log fault codes, making it easier to identify and address issues. Lastly, the ECM contributes to the reliability of the truck by continuously monitoring and adjusting system parameters to prevent malfunctions.

Troubleshooting the Cummins 3965953 ECM

When troubleshooting the Cummins 3965953 ECM, it is important to follow a systematic approach. Begin by checking for any visible signs of damage or loose connections. Use diagnostic tools to read any stored fault codes, which can provide insights into specific issues. Common problems may include sensor malfunctions, wiring issues, or software glitches. Interpreting error codes and consulting the ECM’s diagnostic manual can help identify the root cause of the problem. Potential solutions may involve repairing or replacing faulty components, updating the ECM’s software, or recalibrating sensors.

Maintenance Tips for the Cummins 3965953 ECM

To ensure the optimal performance and longevity of the Cummins 3965953 ECM, regular maintenance is crucial. This includes performing regular checks to ensure all connections are secure and there are no signs of corrosion or damage. Software updates should be applied as they become available, as these can enhance the ECM’s functionality and address any known issues. Environmental considerations, such as protecting the ECM from extreme temperatures and moisture, are also important to prevent damage. Additionally, keeping the ECM’s firmware up to date ensures it continues to operate efficiently.

Integration with Other Systems

The Cummins 3965953 ECM seamlessly integrates with other truck systems to provide comprehensive management of vehicle operations. It works in conjunction with the engine management system to optimize fuel delivery and combustion. The ECM also communicates with the transmission control module to ensure smooth and efficient gear changes. Furthermore, it can interface with aftermarket devices, such as performance tuners or diagnostic tools, to enhance its capabilities and provide additional data for analysis.

Diagnostic Capabilities

The diagnostic capabilities of the Cummins 3965953 ECM are robust, offering valuable insights into the truck’s performance. Onboard diagnostics (OBD) allow for real-time monitoring of various parameters, enabling quick identification of issues. The ECM stores fault codes, which can be retrieved using diagnostic tools to pinpoint specific problems. Real-time data monitoring provides continuous feedback on system performance, allowing for proactive maintenance and adjustments to ensure optimal operation.

Software and Firmware Updates

Software and firmware updates are vital for the Cummins 3965953 ECM to maintain its performance and compatibility with other systems. Updates can introduce new features, improve diagnostic capabilities, and address any bugs or issues identified in previous versions. Performing updates involves connecting the ECM to a diagnostic tool and following the manufacturer’s instructions to download and install the latest software. Keeping the ECM up to date ensures it continues to operate efficiently and effectively.

Cummins Corporation

Cummins Inc. is a renowned manufacturer with a rich history in the commercial truck industry. Founded in 1919, the company has established a strong reputation for producing high-quality engines and components. Cummins offers a wide range of products, including diesel and natural gas engines, filtration systems, and aftermarket parts. The company’s commitment to innovation and customer satisfaction has made it a trusted name in the industry, providing reliable and efficient solutions for commercial truck operators.

Electronic Control Module (Part 3965953) Compatibility with Cummins Engines

The Electronic Control Module (ECM) part number 3965953, manufactured by Cummins, is designed to integrate seamlessly with a variety of Cummins engines. This ECM is a critical component in managing engine performance and ensuring optimal operation. Below is a detailed description of its compatibility with specific Cummins engines:

B5.9 GAS PLUS CM556, C GAS PLUS CM556, L GAS PLUS CM556

The ECM part 3965953 is engineered to work with the B5.9 GAS PLUS CM556, C GAS PLUS CM556, and L GAS PLUS CM556 engines. These engines are part of Cummins’ range of gas-powered engines, known for their reliability and efficiency. The ECM plays a pivotal role in these engines by:

- Managing Fuel Injection: The ECM controls the timing and quantity of fuel injected into the engine, ensuring efficient combustion and optimal performance.

- Monitoring Engine Parameters: It continuously monitors various engine parameters such as temperature, pressure, and RPM, making real-time adjustments to maintain performance and efficiency.

- Emissions Control: The ECM is integral to managing emissions by regulating the air-fuel mixture and ensuring compliance with environmental standards.

- Diagnostic Capabilities: It provides diagnostic information and error codes, aiding in troubleshooting and maintenance.

By integrating with these engines, the ECM ensures that the B5.9 GAS PLUS CM556, C GAS PLUS CM556, and L GAS PLUS CM556 engines operate at peak efficiency, providing reliable performance and reducing downtime.

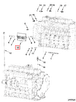

Role of Part 3965953 ECM in Engine Systems

The Electronic Control Module (ECM) part 3965953 is integral to the operation and management of modern engine systems. It interfaces with a variety of components to ensure optimal performance and efficiency.

Integration with Assembly Kit

When installed as part of an assembly kit, the ECM part 3965953 coordinates with sensors and actuators within the kit. This coordination allows for precise control over fuel injection, ignition timing, and other critical functions. The ECM processes data from various sensors and adjusts engine parameters in real-time to maintain performance standards.

Interaction with Electronic Service Calibration

The ECM part 3965953 works in tandem with electronic service calibration processes. During calibration, the ECM is programmed to fine-tune engine performance based on specific requirements or environmental conditions. This ensures that the engine operates within optimal parameters, enhancing both efficiency and reliability.

Coordination with Engine Control Module

Although the terms ECM and Engine Control Module (ECM) are often used interchangeably, it’s important to note that part 3965953 ECM is designed to integrate seamlessly with other ECMs within the engine system. This integration allows for comprehensive management of engine functions, including communication with other control modules such as the transmission control module and the anti-lock braking system module.

The ECM part 3965953 receives data from various engine sensors, processes this information, and sends commands to actuators to adjust engine operations. This continuous feedback loop ensures that the engine responds appropriately to changing conditions, whether it’s load variations, temperature changes, or other operational factors.

Conclusion

In summary, the ECM part 3965953 is a central component in the engine system, facilitating communication and control across multiple subsystems to ensure efficient and reliable engine performance. Its integration with various Cummins engines and its role in managing engine parameters, emissions, and diagnostics make it a critical component for modern commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.